Expandable ultra-filtration centrifugation pipe using AAO porous membrane

A porous membrane and centrifuge tube technology, which is applied in the field of ultrafiltration centrifuge tube preparation, can solve the problems of low retention rate of nanoparticles, low uniformity of pore size, poor filtration effect, etc., achieve accurate and reliable filtration effect, save washing cost, prevent The effect of cross contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

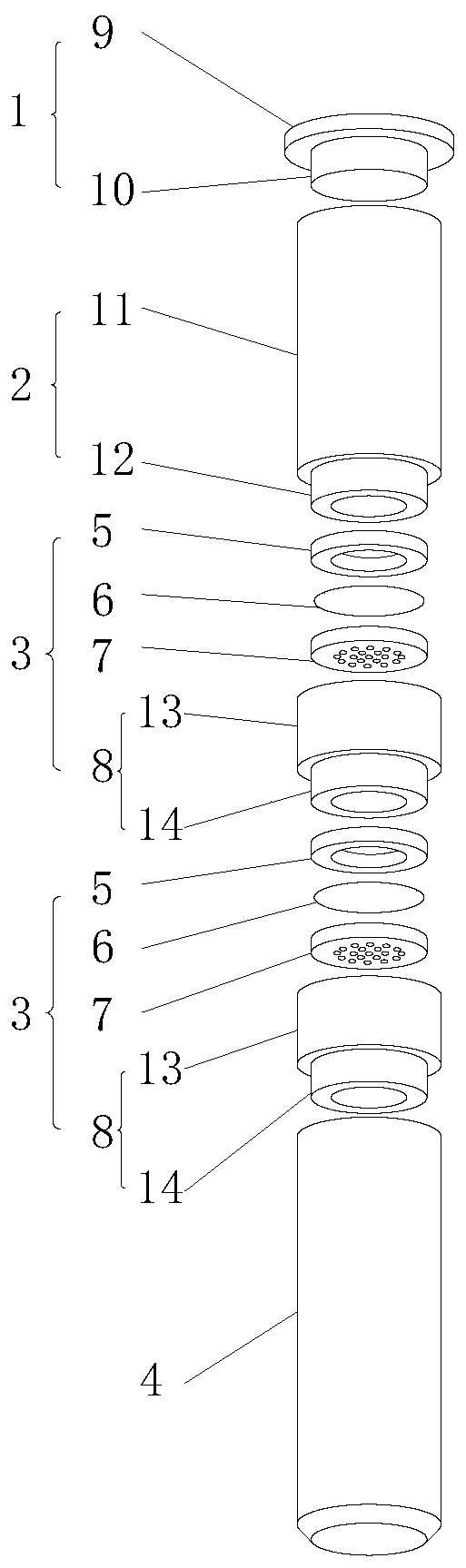

[0031] Embodiment 1 of the present invention: as figure 1 or figure 2 As shown, the expandable ultrafiltration centrifuge tube using AAO porous membrane includes a cover 1, a filtrate cylinder 2, a filter layer 3 and a bottom cylinder 4 connected in sequence, and the cover 1, filtrate cylinder 2, filter layer 3 and bottom cylinder The material of 4 is acrylic.

[0032] The cover 1 includes a cover plate 9 and a boss 10 which are integrally formed and coaxially arranged, the cover plate 9 is a circular thin plate, the boss 10 is cylindrical, and the outer surface of the boss 10 is provided with external threads for use It is connected to the filtrate cartridge 2.

[0033] The filtrate cartridge 2 includes an integrally formed and coaxially arranged filtrate chamber 11 and a first connector 12, the filtrate chamber 11 is a hollow cylinder, the inner diameter of the filtrate chamber 11 is equal to the diameter of the boss 10, and the filtrate chamber The inner side of the cav...

Embodiment 2

[0036] Embodiment 2 of the present invention: as figure 1 or figure 2 As shown, the expandable ultrafiltration centrifuge tube using AAO porous membrane includes a cover 1, a filtrate cylinder 2, three filter layers 3 and a bottom cylinder 4 connected in sequence, and the cover 1, filtrate cylinder 2, filter layer 3 and The material of bottom cylinder 4 is stainless steel.

[0037] The cover 1 includes a cover plate 9 and a boss 10 which are integrally formed and coaxially arranged, the cover plate 9 is a circular thin plate, the boss 10 is cylindrical, and the outer surface of the boss 10 is provided with external threads for use It is connected to the filtrate cartridge 2.

[0038] The filtrate cartridge 2 includes an integrally formed and coaxially arranged filtrate chamber 11 and a first connector 12, the filtrate chamber 11 is a hollow cylinder, the inner diameter of the filtrate chamber 11 is equal to the diameter of the boss 10, and the filtrate chamber The inner si...

Embodiment 3

[0043] Embodiment 3 of the present invention: as figure 1 or figure 2 As shown, the expandable ultrafiltration centrifuge tube using AAO porous membrane includes a cover 1, a filtrate cylinder 2, two filter layers 3 and a bottom cylinder 4 connected in sequence, and the cover 1, filtrate cylinder 2, filter layer 3 and The material of bottom cylinder 4 is acrylic. This example is used for the separation of exosomes in blood. Exosomes in blood are a type of tiny membrane vesicles secreted by cells. It plays a role in biological functions, and its size is between 30 nanometers and 150 nanometers, which is smaller than blood cells and most other vesicles, but larger than free liposomes, proteins, DNA and other particles.

[0044] The cover 1 in the expandable ultrafiltration centrifuge tube includes an integrally formed and coaxially arranged cover plate 9 and a boss 10, the cover plate 9 is a circular thin plate, the boss 10 is cylindrical, and the outer surface of the boss 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com