Method for obtaining atomic-scale dispersed noble metal catalyst by one-step reduction loading

A noble metal catalyst and atomic-level technology, applied in the fields of materials science and engineering technology and chemistry, to achieve the effects of high application range, efficient regulation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

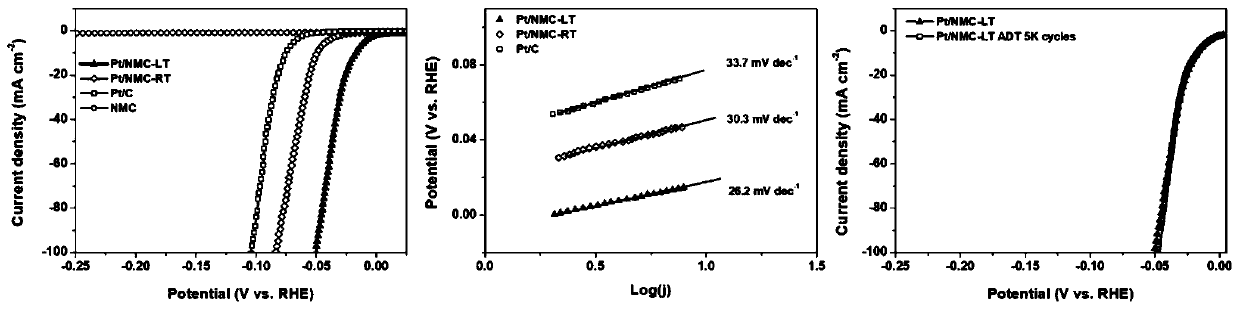

[0024] Preparation of atomically dispersed metal Pt catalysts.

[0025] First, configure reaction solution A: 0.01M H 2 PtCl 6 Solution, the solvent is a water / ethanol mixed solution with a volume ratio of 1:9; reducing agent solution B: ethanol solution; carrier dispersion C: 2.5 mg ml -1 Nitrogen-doped mesoporous carbon dispersions. Next, the above-mentioned solution and dispersion liquid were placed in a low-temperature box, the temperature was lowered to minus 60° C., and the temperature was maintained for 30 minutes. Mix the reducing agent solution B and the carrier dispersion C evenly, add 5ml H 2 PtCl 6 Solution A was added to the well mixed solution. The mixed liquid was stirred continuously for 5-7h at minus 60°C to complete the reduction and loading process. The nitrogen-doped mesoporous carbon-supported Pt single-atom samples were recovered and cleaned by low-temperature vacuum filtration, and then dried naturally at room temperature. An atomically dispersed ...

Embodiment 2

[0027] Preparation of atomically dispersed metal Pt catalysts.

[0028] First, configure reaction solution A: 0.02M H 2 PtCl 6 solution, the solvent is a water / ethanol mixed solution with a volume ratio of 1:9; reducing agent solution B: 5.0M N containing 0.10M KOH 2 h 5 OH hydrazine hydrate solution; carrier dispersion C: 2.5 mg ml -1 Nitrogen-doped mesoporous carbon dispersions. Next, the above-mentioned solution and dispersion liquid were placed in a low-temperature box, the temperature was lowered to minus 40° C., and the temperature was maintained for 30 minutes. Mix the reducing agent solution B and the carrier dispersion C evenly, add 5ml H 2 PtCl 6 Solution A was added to the well mixed solution. The mixed liquid was stirred continuously for 5-7h at minus 40°C to complete the reduction and loading process. The nitrogen-doped mesoporous carbon-supported Pt single-atom samples were recovered and cleaned by low-temperature vacuum filtration, and then dried natural...

Embodiment 3

[0030] Preparation of atomically dispersed metal Pt catalysts.

[0031] First, configure reaction solution A: 0.01M H 2 PtCl 6 solution, the solvent is a water / ethanol mixed solution with a volume ratio of 1:9; reducing agent solution B: 5.0M NaBH containing 0.5M KOH 4 Solution; Carrier Dispersion C: 2.5 mg ml -1 Nitrogen-doped mesoporous carbon dispersions. Next, the above-mentioned solution and dispersion liquid were placed in a low-temperature box, the temperature was lowered to minus 60° C., and the temperature was maintained for 30 minutes. Mix the reducing agent solution B and the carrier dispersion C evenly, add 5ml H 2 PtCl 6 Solution A was added to the well mixed solution. The mixed liquid was stirred continuously for 5-7h at minus 60°C to complete the reduction and loading process. The nitrogen-doped mesoporous carbon-supported Pt single-atom samples were recovered and cleaned by low-temperature vacuum filtration, and then dried naturally at room temperature. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com