Automatic seedling transplanting machine driving device

An automatic seedling transplanter and driving device technology, applied in electromechanical devices, transplanting machinery, planting methods, etc., can solve the problems of slow seedling transplanting speed, soil and root impact, etc., to avoid damage to the root system and improve the effect of soil breaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

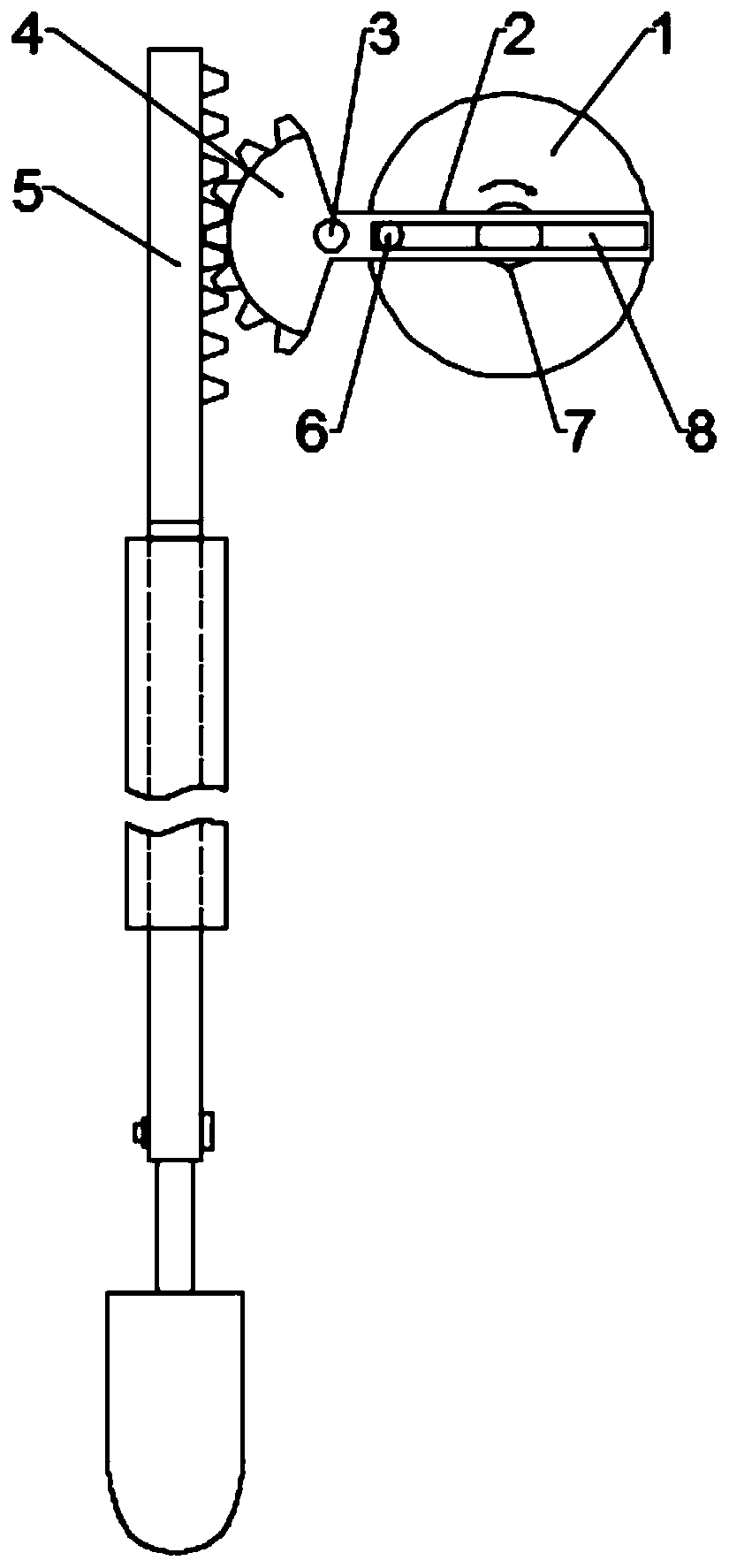

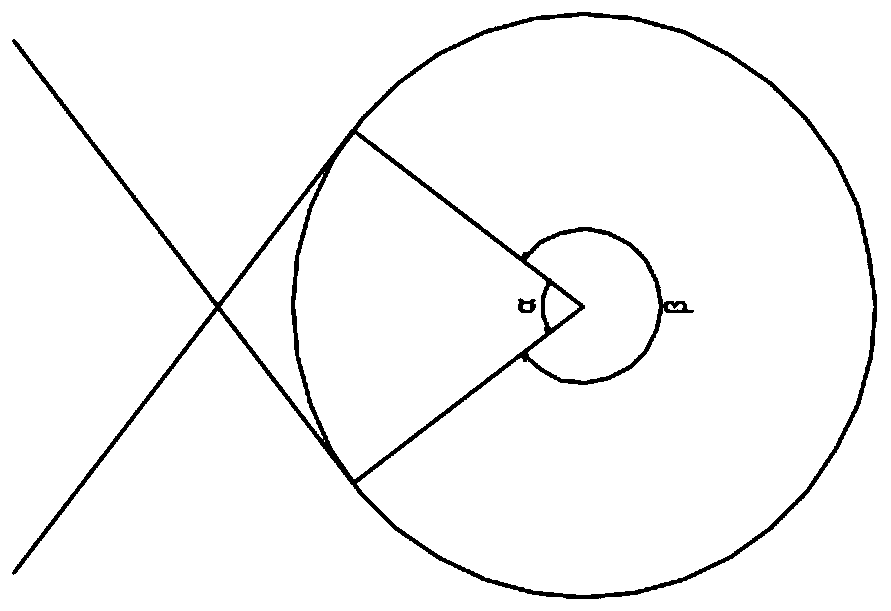

[0019] see Figure 1~2 , in the embodiment of the present invention, a driving device for an automatic seedling transplanting machine includes a motor 7 and a driving member 5, a disk 1 is installed at the end of the output shaft of the motor 7, and a swing rod 2 is connected to the front side of the disk 1 , the outer side of the front end of the disc 1 is integrally provided with a cylindrical pin 6, the swing rod 2 is provided with a chute 8 for the cylindrical pin 6 to penetrate and slide, the end of the cylindrical pin 6 is pierced with a limit pin, the function of the limit pin It is to prevent the cylindrical pin 6 from being separated from the chute 8 due to external force. The left end of the swing rod 2 is welded and fixed with a sector gear 4. The center of the sector gear 4 is pierced with a positioning pin 3. There is a gap between the positioning pin and the center of the sector gear 4. Cooperate, one side of the sector gear 4 is provided with a drive member 5, t...

Embodiment 2

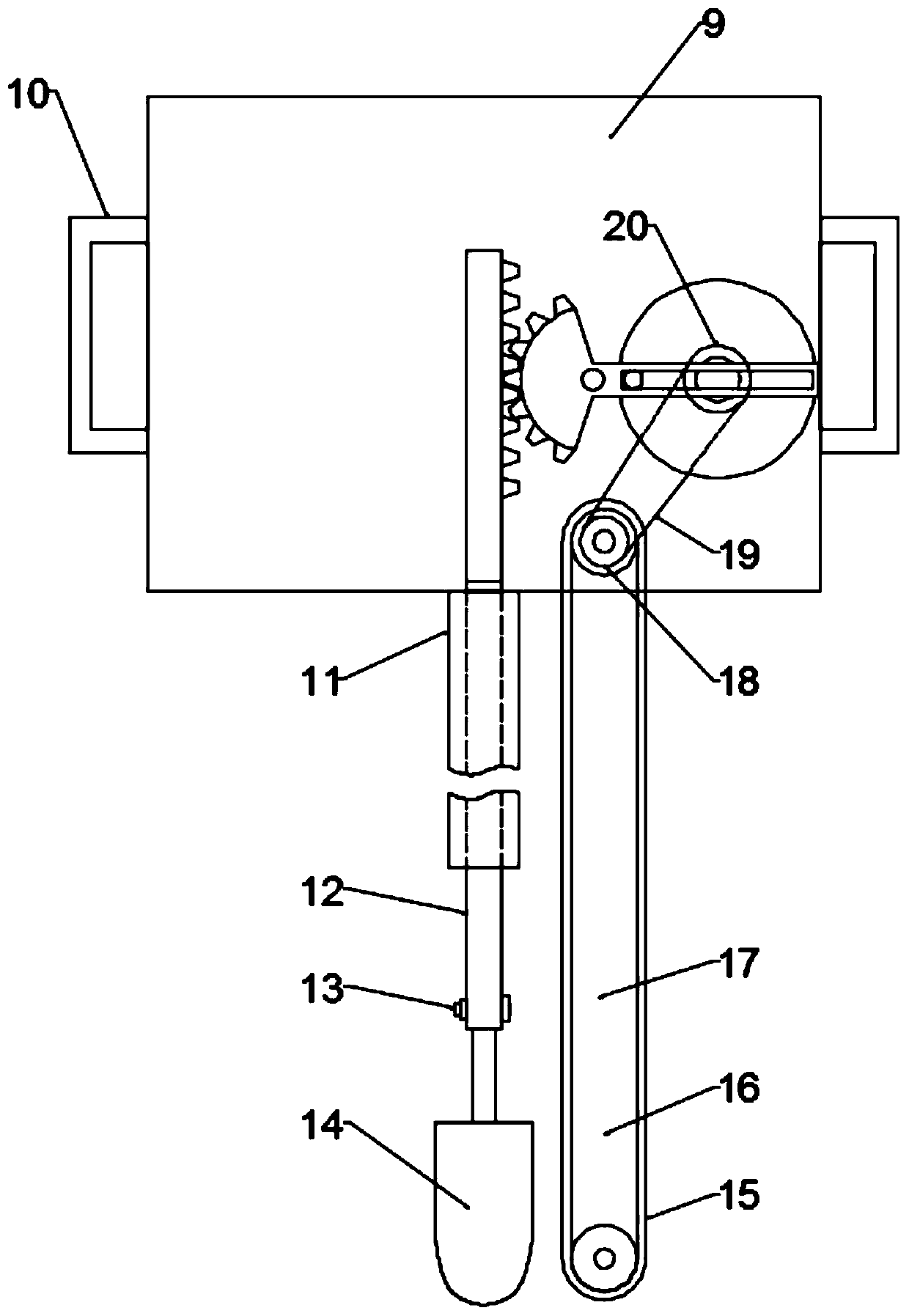

[0021] see image 3 , this embodiment discloses an automatic seedling transplanting machine, including the automatic seedling transplanting machine driving device described in embodiment 1, and also includes a frame 9, a guide sleeve 11, a mounting rod 12 and a shovel head 14, the driving device Installed in the frame 9, the two ends of the frame 9 are welded and fixed with handles 10, the bottom of the frame 9 is welded and fixed with a guide sleeve 11, the bottom of the driver 5 is welded and fixed with a mounting rod 12, and the other end of the mounting rod 12 passes through the guide sleeve 11 And extend to below the guide sleeve 11, the installation rod 12 is matched with the guide sleeve 11 clearance, the shovel head 14 is installed on the bottom end of the installation rod 12 by the bolt 13, and the chain saw 17 is installed on the described frame 9, and the chain saw 17 comprises a chain plate 16, chain wheel and saw blade 15, chain plate 16 is welded and fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com