The saturation method of the graphite frame and the graphite frame

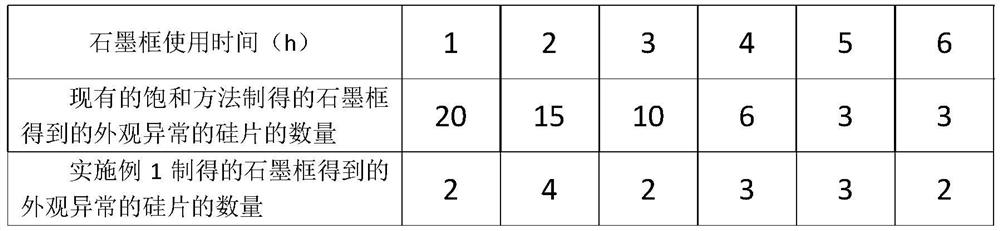

A graphite frame and secondary drying technology, which is applied in the field of solar cells, can solve the problems of affecting the passivation effect of silicon wafers and prone to red edges, so as to improve the passivation effect, prolong the cleaning cycle, and increase the production capacity of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

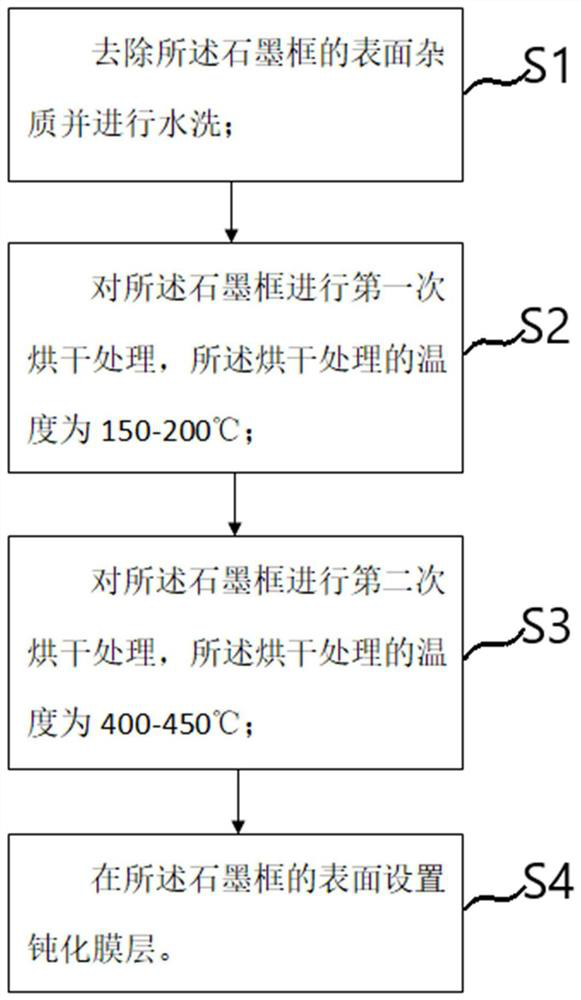

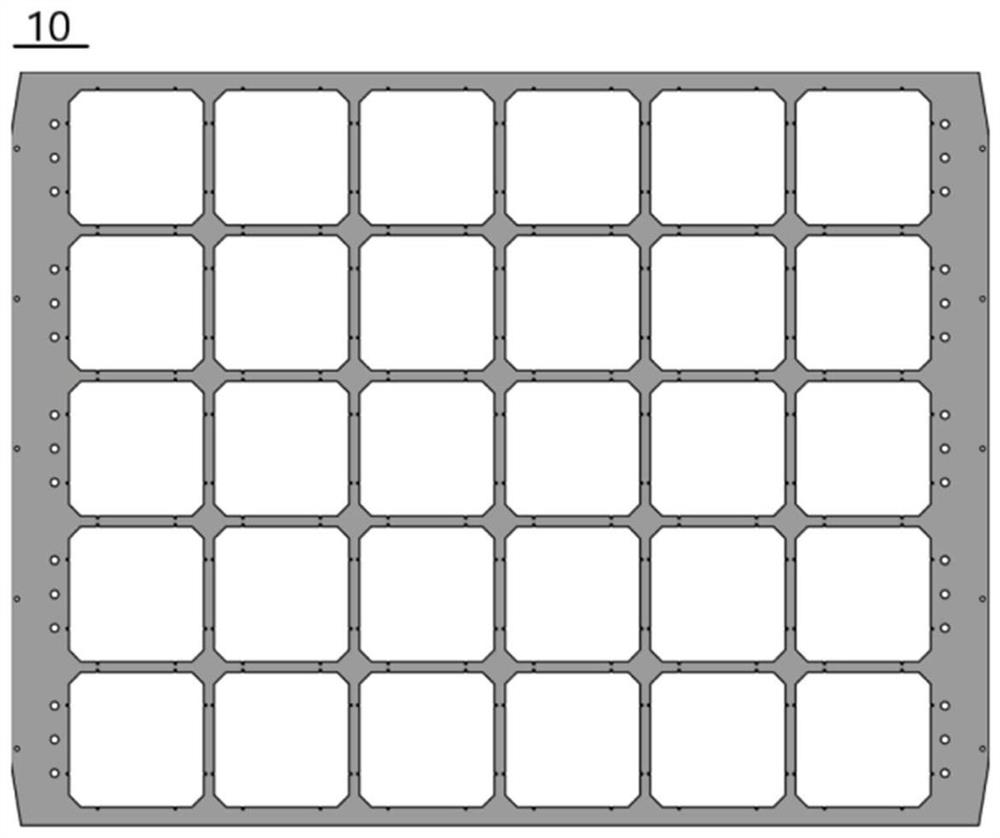

[0050] (1) Take the old graphite frame 10, and use 5% to 15% hydrofluoric acid to clean the graphite frame 10 for 8 hours to remove the silicon nitride passivation layer deposited on the surface of the graphite frame 10;

[0051] (2) Use pure water to rinse the graphite frame 10 after removing the passivation layer for 0.5 hours;

[0052] (3) Use pure water to soak the graphite frame 10 for 4 hours;

[0053] (4) Use an oven to dry the graphite frame 10 for the first time at a temperature of 150°C to 200°C for 6 hours;

[0054] (5) Carry out a second drying treatment on the graphite frame 10 in the plate plasma enhanced chemical vapor deposition equipment, the temperature of the drying treatment is 400-450° C., and the drying treatment time is 1 hour;

[0055] (6) After drying the graphite frame 10 for the second time in the plasma-enhanced chemical vapor deposition equipment, feed ammonia and silane, turn on the radio frequency power supply, and deposit a silicon nitride pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com