A prefabricated building system of box plate steel structure

A technology of building system and steel structure, which is applied in the field of prefabricated building system of box-plate steel structure, which can solve the problems that equipment pipelines are not separated from the structural system, affect the overall service life of the building, and have low matching degree with the flat of the apartment, so as to facilitate industrialization Production, excellent mechanical properties of materials, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

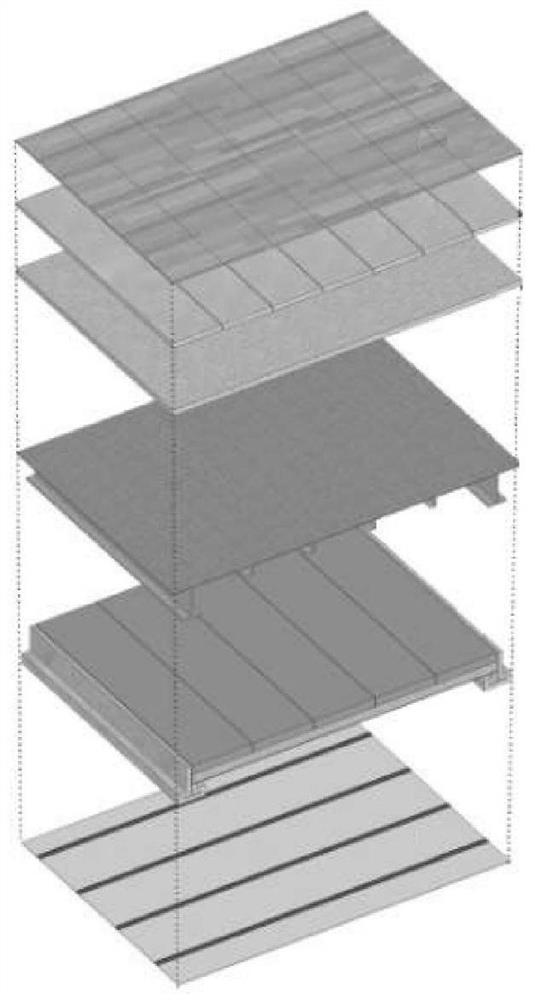

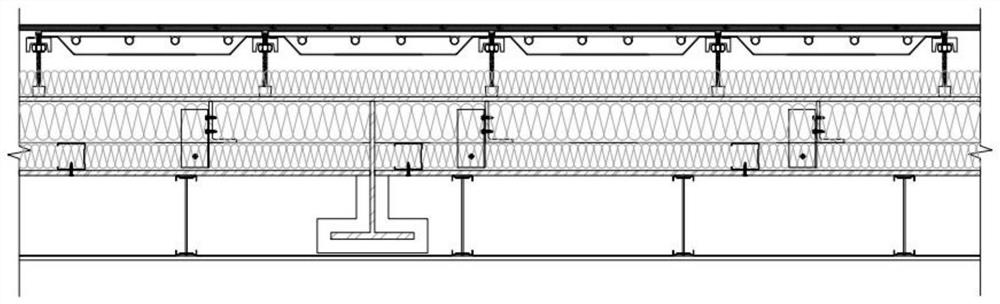

[0060] A specific embodiment of the present invention discloses a prefabricated building system of box-plate steel structure. The building system mainly studies the three parts of the building's outer enclosure structure, inner partition wall structure, and floor structure. Research on configuration and construction methods meets the requirements of building fire protection, heat transfer, sound insulation, and waterproofing, while ensuring the coordination with the interior and exterior decorative surfaces and the ductility and flexibility of the structure itself.

[0061] The box plate steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com