Production method of electrical laminated wood-rubber stick

A technology of electrical laminated wood and a production method, which is applied in the manufacture of wood sticks, the joining and coating of wooden veneers, etc., can solve the problem of the general compressive resistance and voltage breakdown resistance of bakelite sticks, and limit the application of bakelite sticks. range and other issues, to achieve the effect of improving mechanical properties and dielectric properties, compressive capacity and anti-voltage breakdown capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

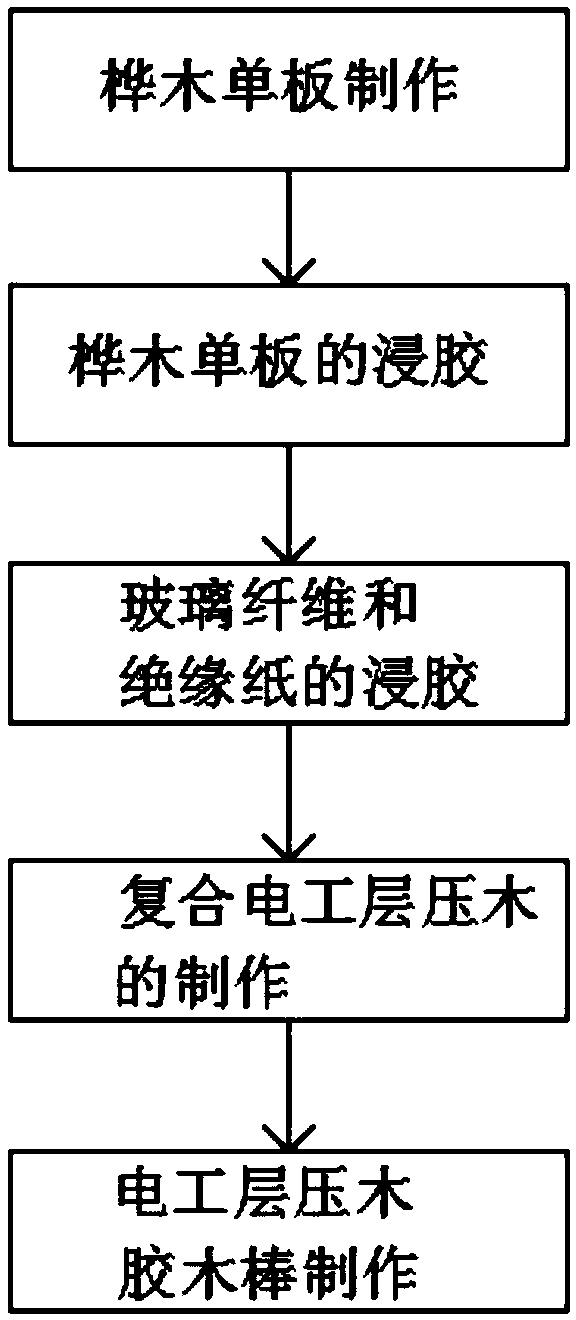

[0020] A method for producing an electrical laminated wood glue stick, comprising the steps of:

[0021] S1: Huamu veneer production, the Huamu is peeled and knotted, the treated Huamu is steamed, the cooked Huamu is naturally cooled, and the cooled Huamu is cut into Huamu veneer.

[0022] S2: Glue dipping of the Huamu veneer, soaking the processed Huamu veneer in a modified phenolic resin, drying the soaked Huamu veneer to obtain a modified Huamu veneer.

[0023] S3: impregnation of glass fiber and insulating paper, taking glass fiber grid cloth and soaking it in modified phenolic resin, drying the soaked glass fiber grid cloth to obtain modified glass fiber grid cloth;

[0024] The insulating paper is soaked in the modified phenolic resin, and the soaked insulating paper is dried to obtain the modifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com