Internal high-pressure formed auxiliary frame and forming method thereof

A technology of internal high pressure forming and sub-frame, which is applied to vehicle components, substructure, transportation and packaging, etc., and can solve problems such as increasing design and development cycle and manufacturing cost, increasing sub-frame development molds, and difficulty in sub-frame layout , to achieve the effect of shortening the design cycle, saving production investment and improving competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

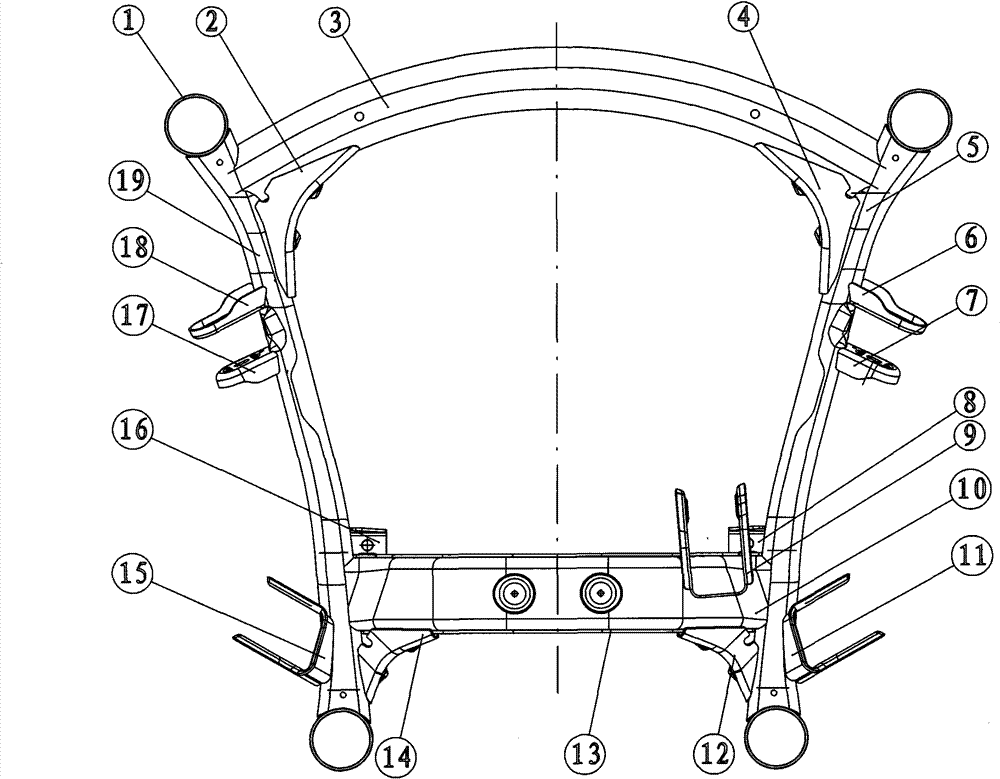

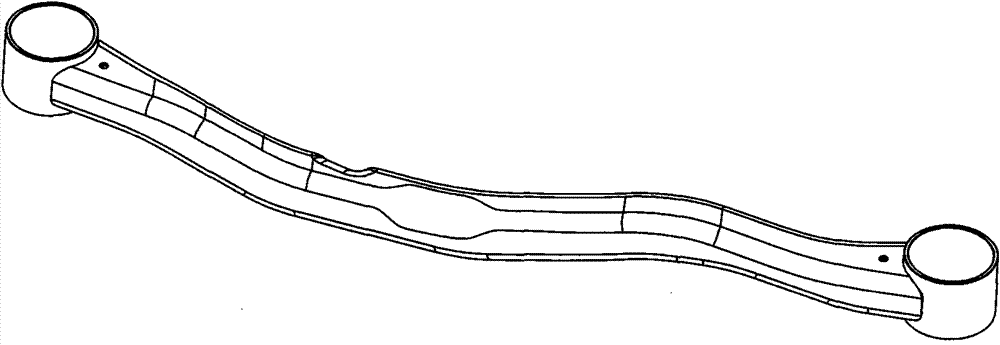

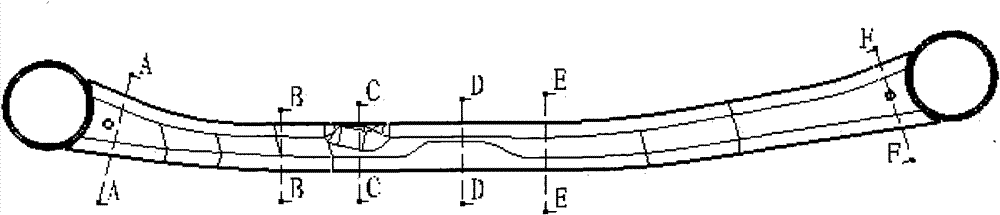

[0036] see Figure 1 to Figure 9 Shown, the subframe connection structure of the present invention consists of two longitudinal beams (5,19), a front beam (3), rear beam upper and lower plates (10,13), six swing arm supports (6,7, 11, 15, 17, 18), four reinforcement plates (2, 4, 12, 14), four bushing sleeves (1), two stabilizer bar brackets (8, 16) and one engine rear suspension bracket (9 ) welded, this sub-frame overall frame structure has the characteristics of high strength and good rigidity, sub-frame longitudinal beams (5, 19) and front beam (3) are formed by internal high pressure, Figure 4 to Figure 9 The individual cross-sectional shape characteristics of the stringer are shown.

[0037] The sub-frame longitudinal beam and the front beam adopt the internal high-pressure forming technology of pipe fittings, which is suitable for h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com