Deformation joint later-burying type waterstop belt and mounting method thereof

An installation method and deformation joint technology, which are applied in building components, building insulation materials, buildings, etc., can solve the problems of easy damage to filler strips, failure of rubber waterstops, short service life, etc., and achieve good welding fixing effect and welding. Mature, the effect of improving waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

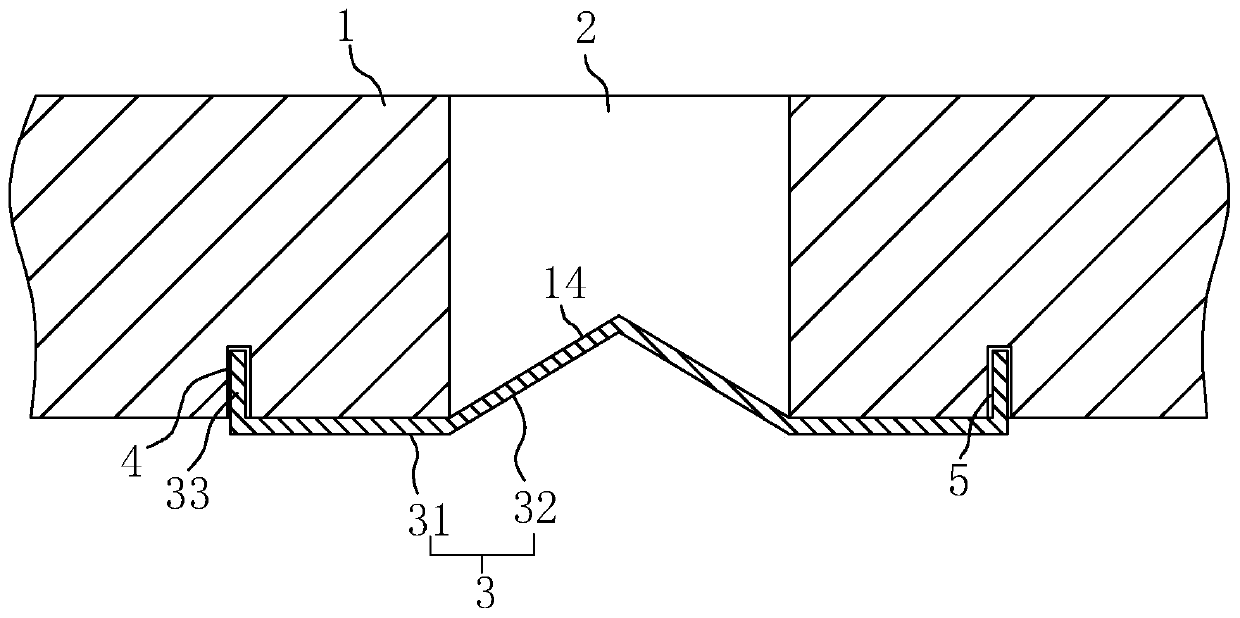

[0045] Example 1: A buried waterstop behind a deformation joint, such as figure 1 As shown, it includes a deformation joint 2 reserved on the concrete wall 1, and a water stop plate 3 is provided on the side of the deformation joint 2 facing the interior, and the water stop plate 3 includes a V-shaped bending part in the middle. 32 and the wing plates 31 on both sides, wherein the bent part 32 and the wing plate 31 are integrally set and fixed on the surface of the concrete wall 1 through the wing plate 31; there are installation joints on the surface of the concrete wall 1 on both sides of the deformation joint 2 4. The width of the installation seam 4 is 5 mm, and the depth of the seam is 20-30 mm. In this embodiment, the seam depth of the installation seam 4 is 25 mm. 4 Inserting the plug-in part 33, by injecting the anchoring agent 5 in the installation seam 4, the model of the anchoring agent 5 is GCYY-201, and fixing the water-stop plate 3 after the anchoring agent 5 sol...

Embodiment 2

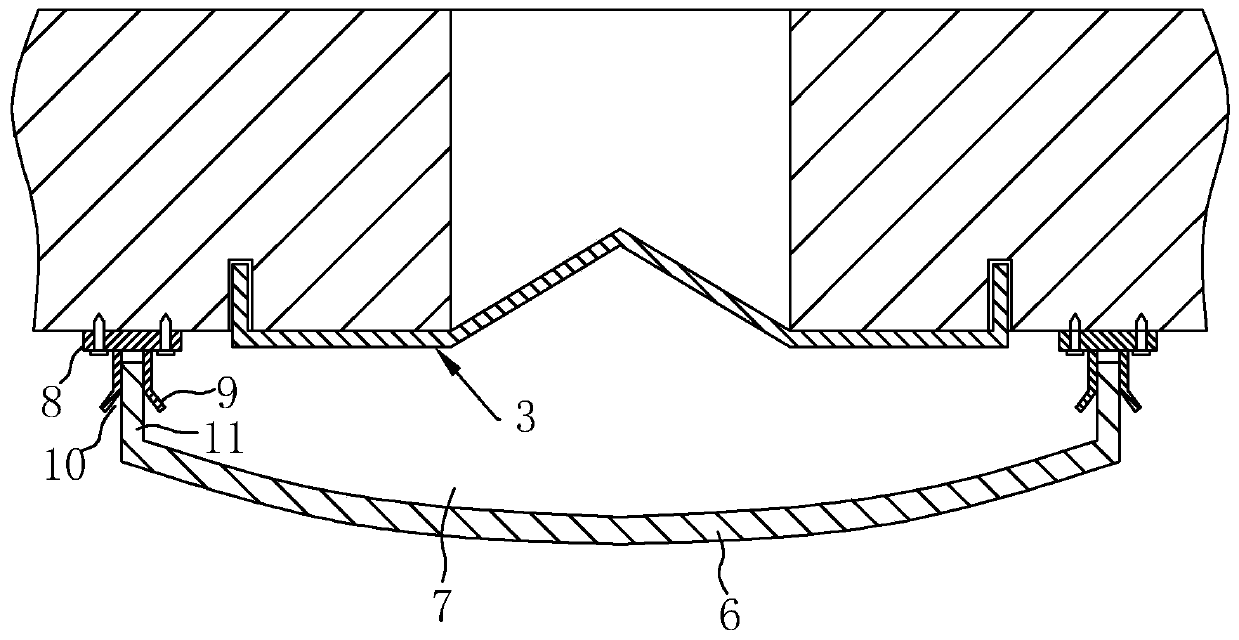

[0049] Example 2: A buried waterstop behind a deformation joint, such as image 3 As shown, the main difference from Embodiment 1 is that an additional water receiving plate 6 is added. The water receiving plate 6 is arranged on the indoor side of the water stop plate 3. The water receiving plate 6 is U-shaped and forms a water receiving tank 7. A base 8 is arranged on the surface of the concrete wall 1, and the base 8 is fixed on the concrete wall 1 by screws, and polyurethane waterproof glue is applied at the joint between the base 8 and the concrete wall 1, which is The base 8 ensures the waterproofness of the connection between the base 8 and the concrete wall 1 while reinforcing; There are inserts 11 that fit into the slots 10 at the two side edges of the two sides; through the further setting of the water-receiving plate 6, a double waterproof effect can be achieved, even if the water-stopping plate 3 accidentally leaks, the water can be caught by the water Plate 6 unde...

Embodiment 3

[0050] Example 3: A buried waterstop behind a deformation joint, such as Figure 4 and Figure 5 As shown, the difference between it and Embodiment 1 is mainly that the insertion portion 33 is tapered, and the width of the insertion portion 33 gradually increases from one end away from the wing plate 31 to the other end, and in the horizontal direction at the end of the insertion portion 33 The protruding part 12 protrudes outward, so that on the one hand, it is convenient for the insertion part 33 to be plugged into the installation seam 4, and on the other hand, the protruding part 12 is laterally trapped in the solidified anchoring agent 5, which can play a good role in preventing detachment, and The amount of anchoring agent 5 at the bottom wall of the installation slot 4 is larger, so that the fixation of the insertion part 33 is better.

[0051] In addition, glue grooves 13 are arranged at intervals on the surface of the wing plate 31 close to the insertion portion 33 f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com