Edible environment-friendly straw and preparation method thereof

A straw, an environmentally friendly technology, applied in the field of edible and environmentally friendly straws and its preparation, can solve the problems of insufficient waterproof performance, poor taste, and low mechanical strength, and achieve the effects of lower unit price, short decomposition cycle, and no toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

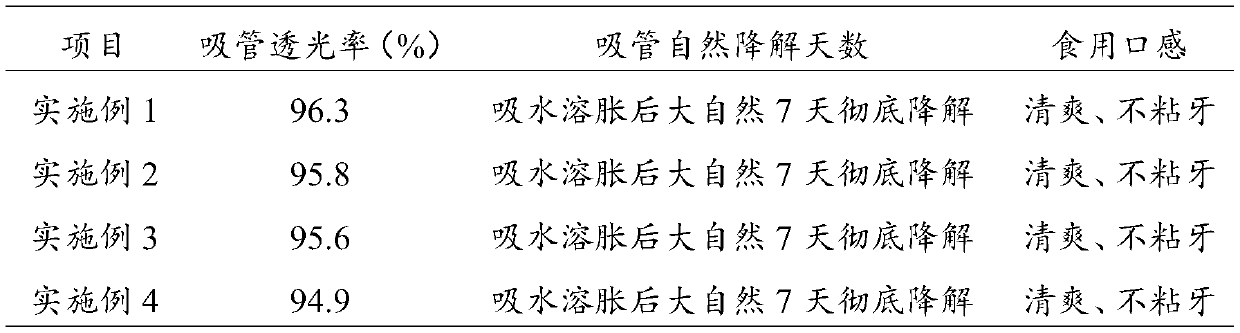

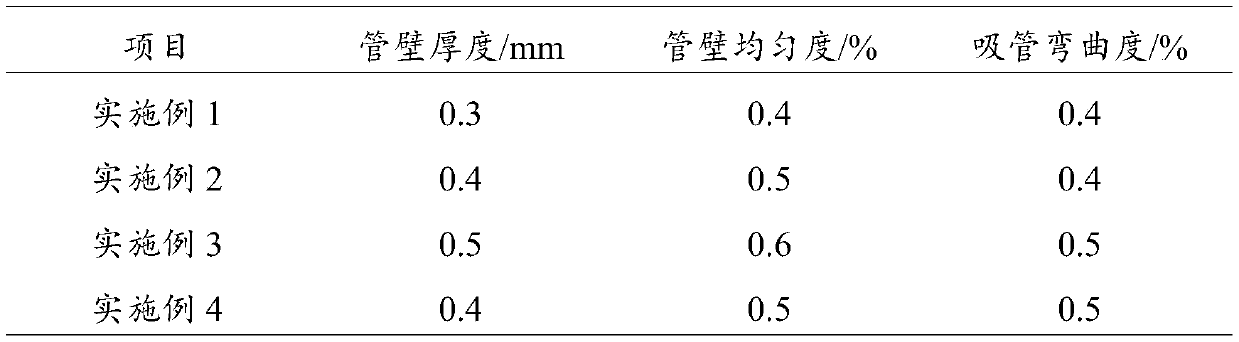

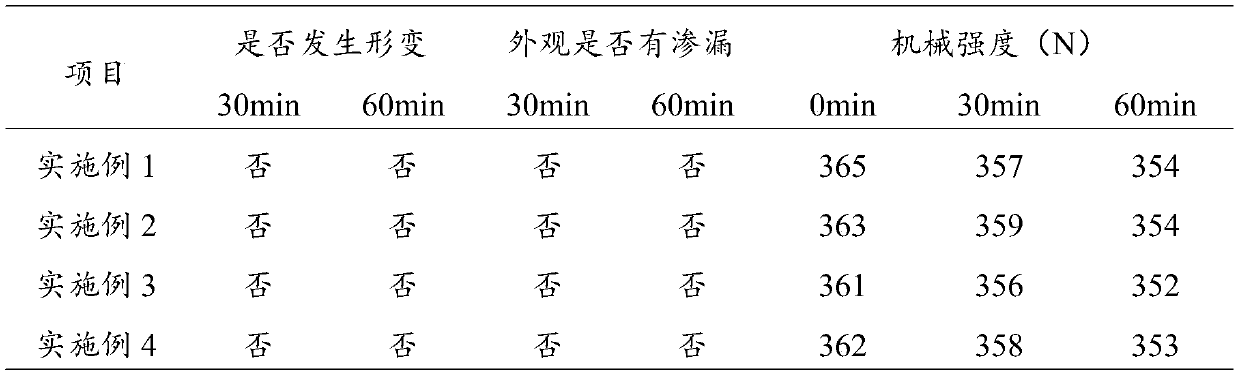

Examples

Embodiment 1

[0024] An edible environmental straw, comprising the following raw materials in parts by weight: 100 parts of sorghum flour, 15 parts of pure water, 1 part of food coloring, 0.1 part of table salt, 0.3 part of sodium carboxymethylcellulose, 0.2 part of calcium propionate and 0.3 part of mango powder share.

[0025] S1. Superfinely crushing and sieving the sorghum flour of the weight portion to make a mixed superfine powder;

[0026] S2. Add the weight of pure water to the ultrafine powder prepared in step S1 and soak for 2 hours, then add 0.3% of the mixed enzyme solution of the weight of the ultrafine powder, stir evenly, and enzymolyze it for 1 hour at 35°C to obtain a mixed enzymatic solution;

[0027] The mixed enzyme liquid is formed by mixing red yeast rice esterase, compound plant hydrolase, and amylase at a weight ratio of 1:6:8, wherein the red yeast rice esterase is food grade, with an enzyme activity of 200u / g, and the compound plant The hydrolase is food grade, t...

Embodiment 2

[0033] An edible environment-friendly straw comprises the following raw materials in parts by weight: 105 parts of corn flour, 15 parts of pure water, 0.1 part of table salt, 0.3 part of sodium carboxymethylcellulose, 0.2 part of calcium propionate and 0.3 part of mango powder.

[0034] S1. The corn flour of the weight part is made into a mixed superfine powder through ultrafine pulverization and sieving;

[0035] S2. Add the weight of pure water to the ultrafine powder prepared in step S1 and soak for 2 hours, then add 0.3% of the mixed enzyme solution of the weight of the ultrafine powder, stir evenly, and enzymolyze it for 1 hour at 35°C to obtain a mixed enzymatic solution;

[0036] The mixed enzyme liquid is formed by mixing red yeast rice esterase, compound plant hydrolase, and amylase at a weight ratio of 1:6:8, wherein the red yeast rice esterase is food grade, with an enzyme activity of 200u / g, and the compound plant The hydrolase is food grade, the enzyme activity i...

Embodiment 3

[0042] An edible environmental straw comprises the following raw materials in parts by weight: 120 parts of buckwheat flour, 20 parts of pure water, 2 parts of food coloring, 0.2 part of table salt, 0.4 part of glycerin, 0.3 part of potassium sorbate and 0.5 part of vanilla bean powder.

[0043] The preparation method of the above-mentioned edible environment-friendly straw comprises the following steps:

[0044] S1. The buckwheat flour of the weight part is made into mixed superfine powder through superfine pulverization and sieving;

[0045] S2. Add the weight of pure water to the ultrafine powder prepared in step S1 and soak for 3 hours, then add 0.5% of the mixed enzyme solution of the weight of the ultrafine powder, stir evenly, and enzymolyze for 2 hours at 40°C to obtain a mixed enzymatic solution;

[0046] The mixed enzyme liquid is made by mixing red yeast rice esterase, compound plant hydrolase, and amylase at a weight ratio of 1:10:7, wherein the red yeast rice est...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com