Combined treatment method of electric discharge of waste battery and desulfuration of waste water containing sulfur

A waste battery and combined treatment technology, which is applied in the direction of gaseous discharge wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of unsatisfactory discharge effect, long discharge time, sulfur pollution in industrial wastewater, etc., to achieve Achieve cascade utilization and shorten discharge time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

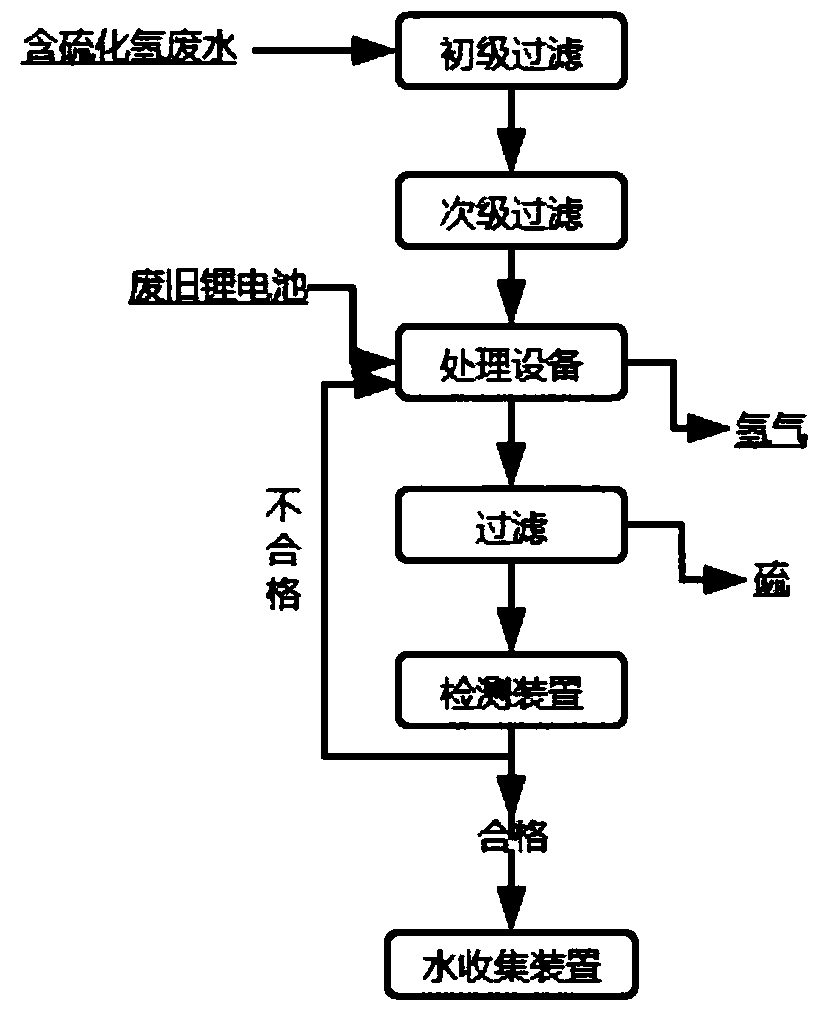

[0048] Such as figure 1 Shown, the present invention is a kind of method for the hydrogen sulfide in waste water that the residual energy cascade utilization in a kind of battery, industrial waste water (in the waste water, the existence form of sulfur is S 2- and HS - , the total mass fraction of sulfur is at 9.6wt.%) through the primary filter to remove the suspended matter with a particle size greater than 0.5mm in advance; then carry out secondary filtration, add an adsorbent during the secondary filter and centrifugally filter to remove the suspended matter with a particle size less than 0.5mm A secondary filtrate was obtained. The pH value of the secondary filtrate is about 7.3 (7.3 ± 0.1), and the secondary filtrate is sent to the reaction device equipped with waste lithium batteries (soaking the waste lithium batteries in the secondary filtrate) for discharge treatment. The generated gas is collected to obtain high-purity hydrogen, and after sufficient time to react,...

Embodiment 2

[0054] Take 10L of industrial waste water, and after primary filtration and secondary adsorption filtration, the sulfur content of the secondary filtrate without suspended solids is determined to be 9.6wt.%. Then pour the secondary filtrate into a closed device with waste batteries. The initial voltage of the waste batteries is 3.8-3.85V. Add sulfuric acid to adjust the pH value of the filtrate to about 1. At this time, the sulfur in the solution is 2 S, HS- exists in the form. After 24 hours of discharge, the sulfur content was determined to be 0.73wt.%, the average residual voltage of the waste battery was around 0.5V, and the gas composition in the gas collection device was analyzed to find that the hydrogen gas fraction was 73%, and the hydrogen sulfide volume fraction was 25%. It can be seen that hydrogen sulfide gas is released in acidic environment.

Embodiment 3

[0056] Take 10L of industrial waste water, and after primary filtration and secondary adsorption filtration, the sulfur content of the secondary filtrate without suspended solids is determined to be 9.6wt.%. Then pour the secondary filtrate into a closed device containing waste batteries, the initial voltage of which is 3.8-3.85V. Add sodium hydroxide to adjust the pH value of the filtrate to about 10 (10 ± 0.1). 2- form exists. After 24 hours of discharge, the sulfur content was determined to be 0.13wt.%, the average residual voltage of the waste battery was around 0V, the gas composition in the gas collection device was analyzed and the hydrogen gas fraction was 98%, and no hydrogen sulfide gas was detected. It can be seen that no hydrogen sulfide gas is released under alkaline environment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com