Cobaltous oxide slice, preparation method thereof and application of cobaltous oxide slice in visible-light photocatalysis total-decomposition of water

A cobalt oxide, flake technology, applied in the field of photocatalytic water splitting, to achieve the effect of excellent performance, high activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a method for preparing cobaltous oxide flakes, comprising the following steps:

[0039] S1. Using sodium chloride as a template and cobalt acetate as a cobalt source, obtain precursor flakes through hydrothermal reaction or solvothermal reaction;

[0040] S2. Calcining the precursor flakes at 200-300° C. in an inert atmosphere to obtain sphalerite-type cobaltous oxide flakes.

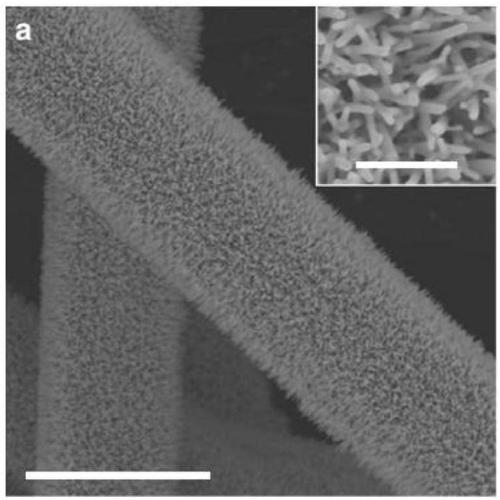

[0041] Aiming at the status quo of visible light catalytic total water splitting in the prior art, this application provides a preparation method of sphalerite-type CoO ultra-thin flakes. The ultra-thin flakes prepared above can realize the catalytic decomposition of water under visible light, and the product Has high stability.

[0042] Specifically, the embodiment of the present invention discloses a preparation method of sphalerite-type CoO ultrathin flakes, including the following steps:

[0043] Sodium chloride and cobalt acetate are dispersed and reacted in water or...

Embodiment 1

[0063] Add 320mg of sodium chloride and 500mg of cobalt acetate tetrahydrate into 20mL of water, stir vigorously at room temperature for 30min, pre-cool the resulting reaction solution, put it into a freeze dryer, and freeze-dry for 24h to obtain a precursor powder; take 50mg of the obtained precursor powder In a tube furnace, calcined at 240°C for 3 hours in a high-purity argon atmosphere, took it out after natural cooling to obtain a powder product, washed with water to remove sodium chloride, centrifuged to obtain a sample, and dried the sample in a vacuum oven at 60°C for 10 hours to obtain 10-13mg of powder, that is, sphalerite-type CoO flakes.

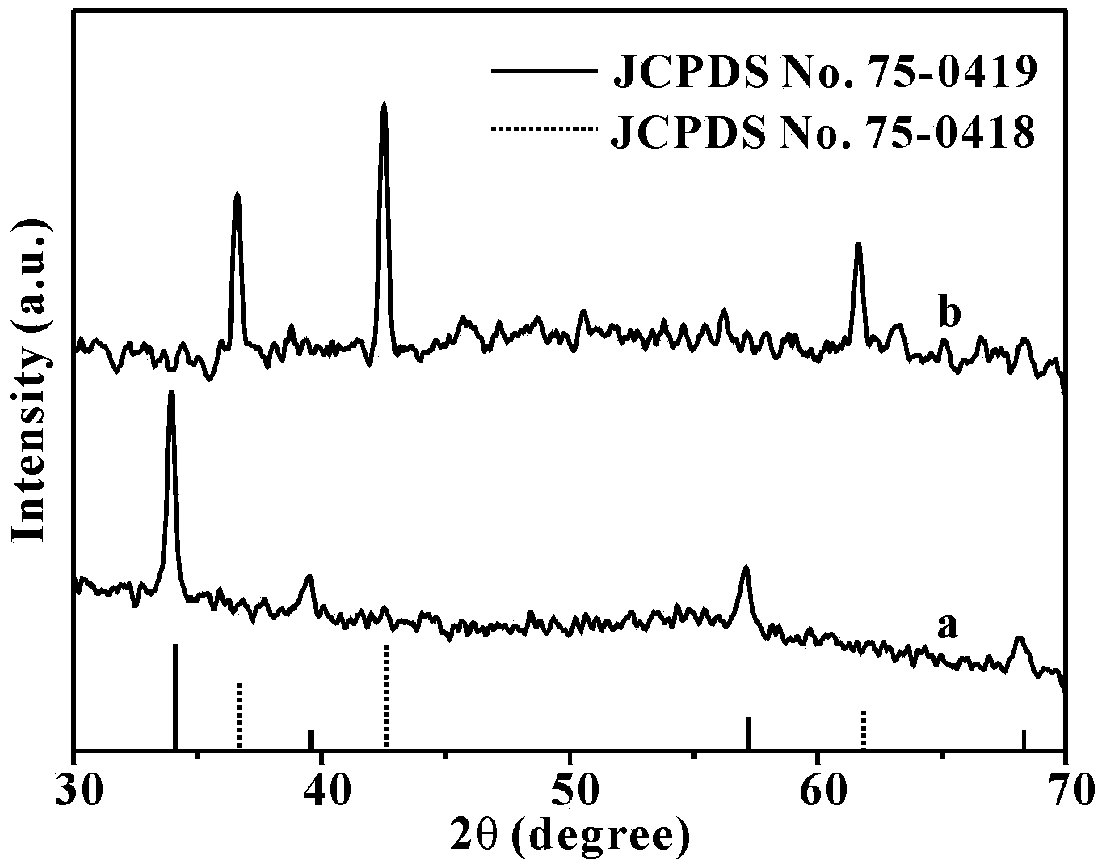

[0064] The compound prepared in Example 1 is carried out structural identification, the results are shown in Figure 3 ~ Figure 6 , image 3 The curve a in the middle is the X-ray diffraction (XRD diffraction) pattern of the sphalerite-type CoO flakes prepared in this example, where the ordinate is the intensity (Intensity), and...

Embodiment 2

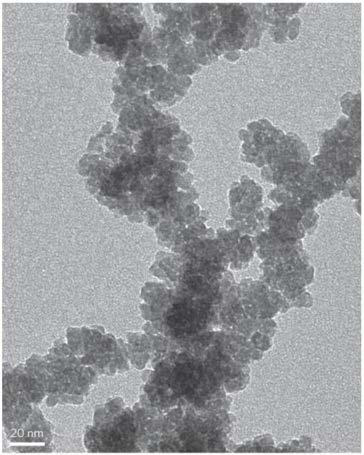

[0073] Add 320mg of sodium chloride and 500mg of cobalt acetate tetrahydrate into 20mL of water, stir vigorously at room temperature for 30min, and dry the resulting reaction solution at 65-75°C for 24h to obtain a precursor powder; take 50mg of the obtained precursor powder in a tube furnace, Calcined at 240°C for 3 hours in a high-purity argon atmosphere, cooled naturally to obtain a powder product, washed with water to remove sodium chloride, and then centrifuged to obtain a sample, dried the sample in a vacuum drying oven at 60°C for 10 hours to obtain 10-13 mg of powder, That is, sphalerite-type CoO flakes, whose TEM photos are as follows Figure 12 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com