Landing device for vertical lifting aircraft and ship

A vertical lift and aircraft technology, applied in the field of ships, can solve the problems of hitting the deck, not suitable for lift, and not strong in versatility, so as to achieve the effect of buffering the impact force and avoiding strong vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

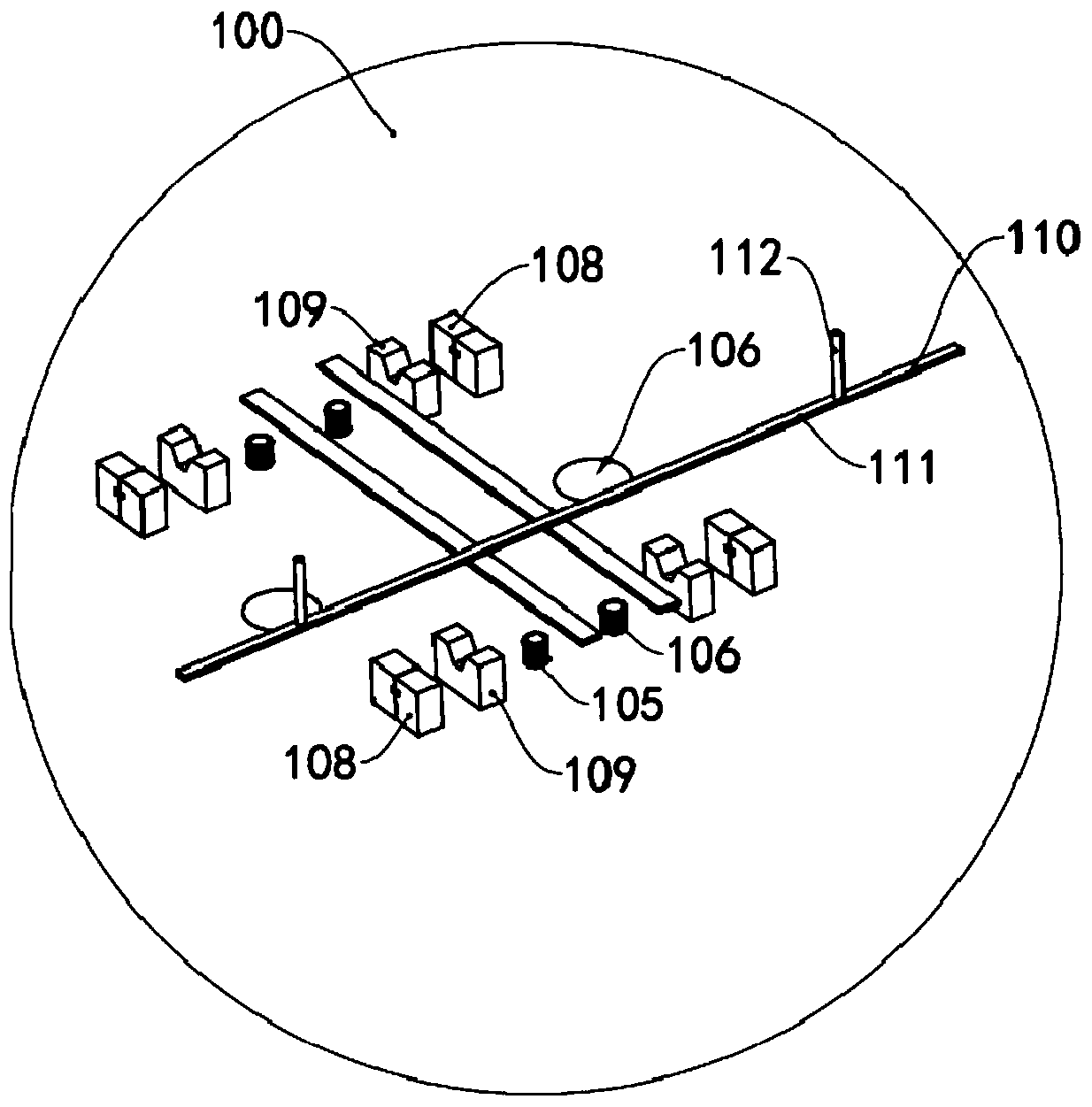

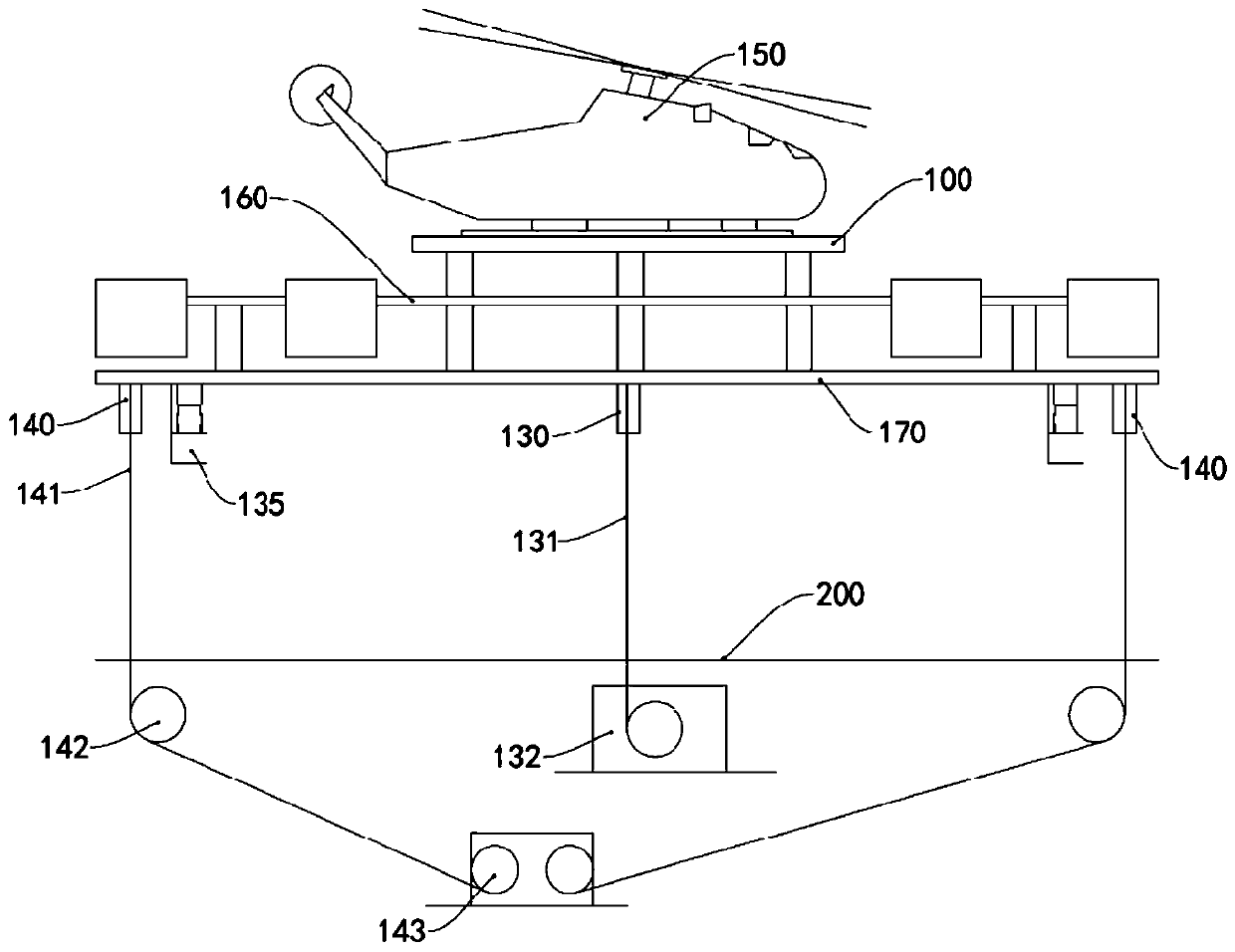

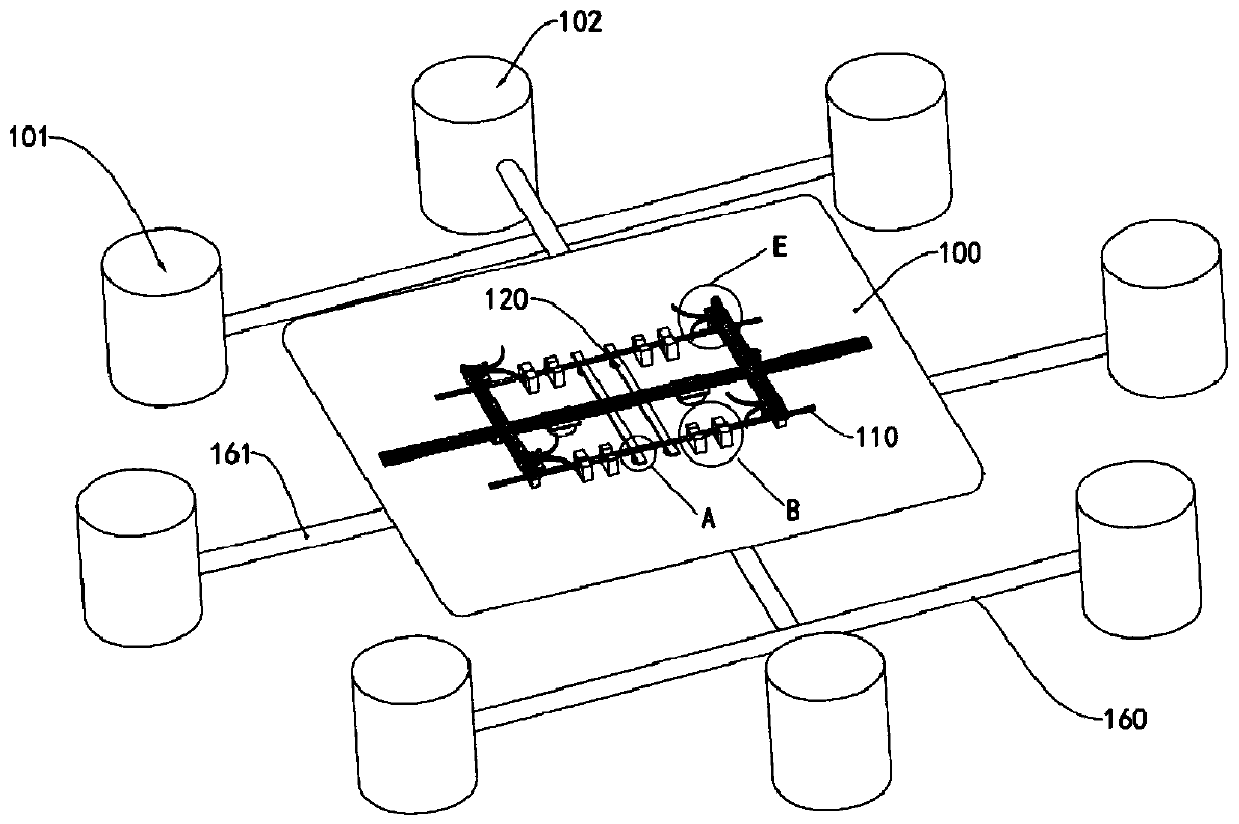

[0075] The ship landing device of this embodiment is mainly applied to the landing of vertical lift aircraft such as helicopters and vertical lift unmanned aerial vehicles on ships, so as to avoid landing accidents.

[0076] see figure 1 , the ship includes a hull, the hull is provided with a deck 200, and the lift-off platform is arranged on the deck 200. The lift-off platform of the present embodiment includes a three-layer structure, which is an upper platform 100, a power plant, and a power plant that are sequentially arranged from top to bottom. The layer 160 and the connection layer 170 are fixedly connected by rigid materials, such as steel pipes, among the three layers. The aircraft 150 is locked on the upper platform 100 and lands on the deck 200 together with the lift-off platform, so that the aircraft 150 can be prevented from directly landing on the deck 200 and the rigid collision between the aircraft 150 and the violently shaking deck 200 can be avoided.

[0077...

no. 2 example

[0109] see Figure 16 , the ship in this embodiment has a hull, the hull is provided with a deck 350 , and a lift-off platform 300 is arranged above the deck 350 , and the aircraft 380 can land on the lift-off platform 300 . A magnet 381 is disposed under the belly of the aircraft 380 , preferably, the magnet 381 is flat and has a large area. The landing gear of the aircraft 380 is a skid type landing gear 382 , of course, the aircraft 380 may also adopt a wheel type landing gear.

[0110] In this embodiment, the lift-off platform 300 includes an upper platform 305, a power plant layer 301 and a connecting layer 302. Power devices such as rotors or turbofan engines are arranged on the power plant layer 301. For example, a rotor mounting frame 303 is set on the power plant layer 301 and The turbofan engine mounting frame 304 is driven by the power unit to raise or lower the lift-off platform 300 . In addition, a main probe 330 and a plurality of auxiliary probes 340 are arran...

no. 3 example

[0117] The ship of this embodiment has a hull, a deck is provided on the hull, and a lift-off platform is arranged above the deck, and the aircraft can land on the lift-off platform. Power devices such as rotors or turbofan engines are arranged on the lift-off platform to drive the lift-off platform to rise or fall. In addition, a main probe and multiple auxiliary probes are arranged under the lift-off platform. A main drop cable is arranged in the main probe tube, an auxiliary drop cable is arranged in the auxiliary probe tube, the main drop cable is wound on the main pull winch, and the auxiliary drop cable is wound on the auxiliary drop winch. Moreover, the landing device also includes a cable winch arranged below the deck, the power cable is connected to the cable winch, and the cable winch can release or recover the power cable.

[0118] see Figure 19 and Figure 20 , The locking device of this embodiment includes a telescopic rod 400, the telescopic rod 400 is a hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com