Lateral core-pulling mechanism capable of pushing and returning on oblique plane and method

A lateral core-pulling and push-out mechanism technology, applied in the field of molds, can solve the problems of easy interference in laterally-molded parts extraction and reset, increased operating procedures, long core-pulling distance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

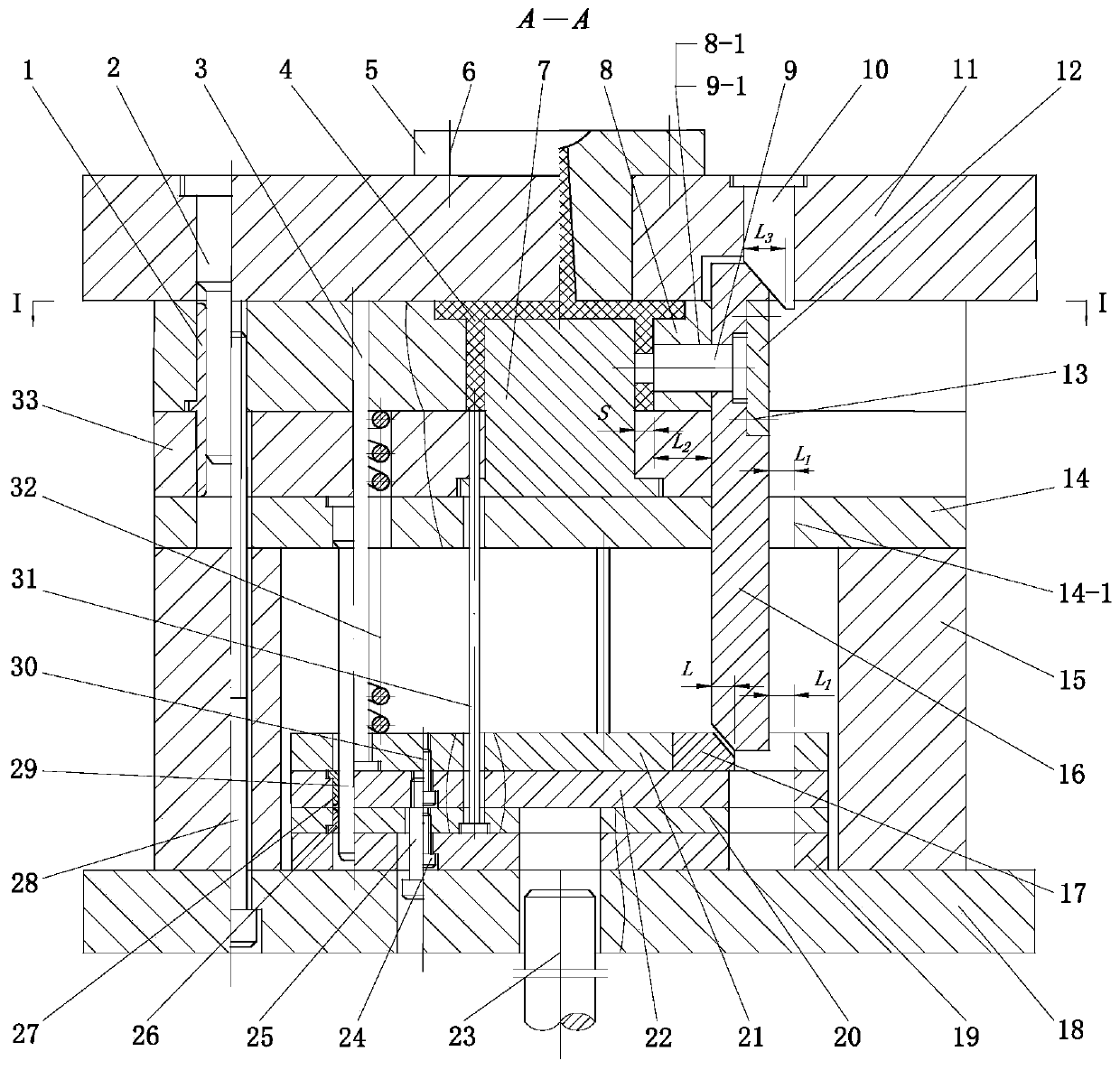

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

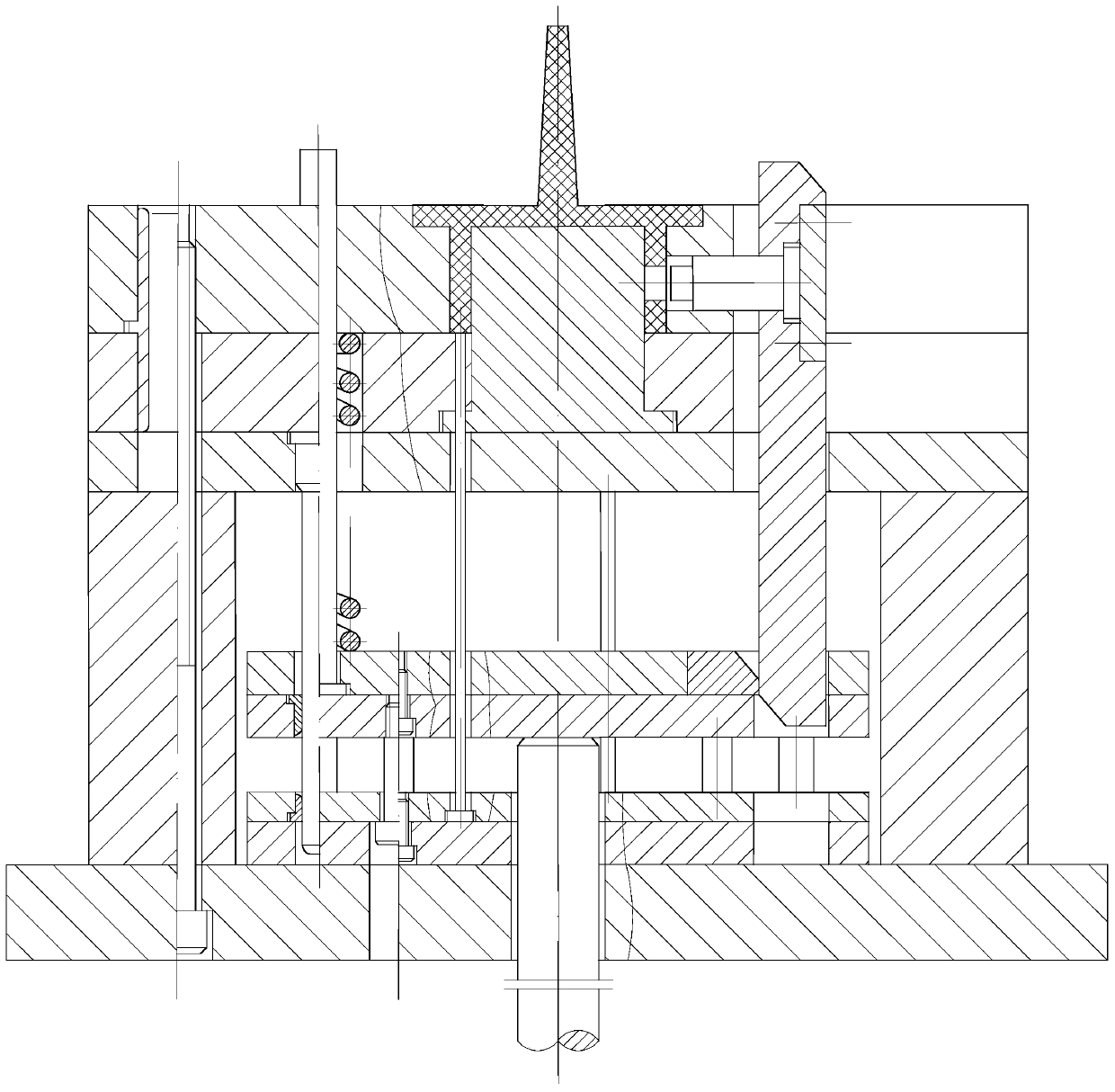

[0043] This embodiment is used for injection molding mould, and mold is installed on the horizontal injection machine. After the injection molding is completed, under the action of the mold opening mechanism of the injection machine, the movable mold part moves along the figure 1 The shown parting surface I-I retreats to the set position.

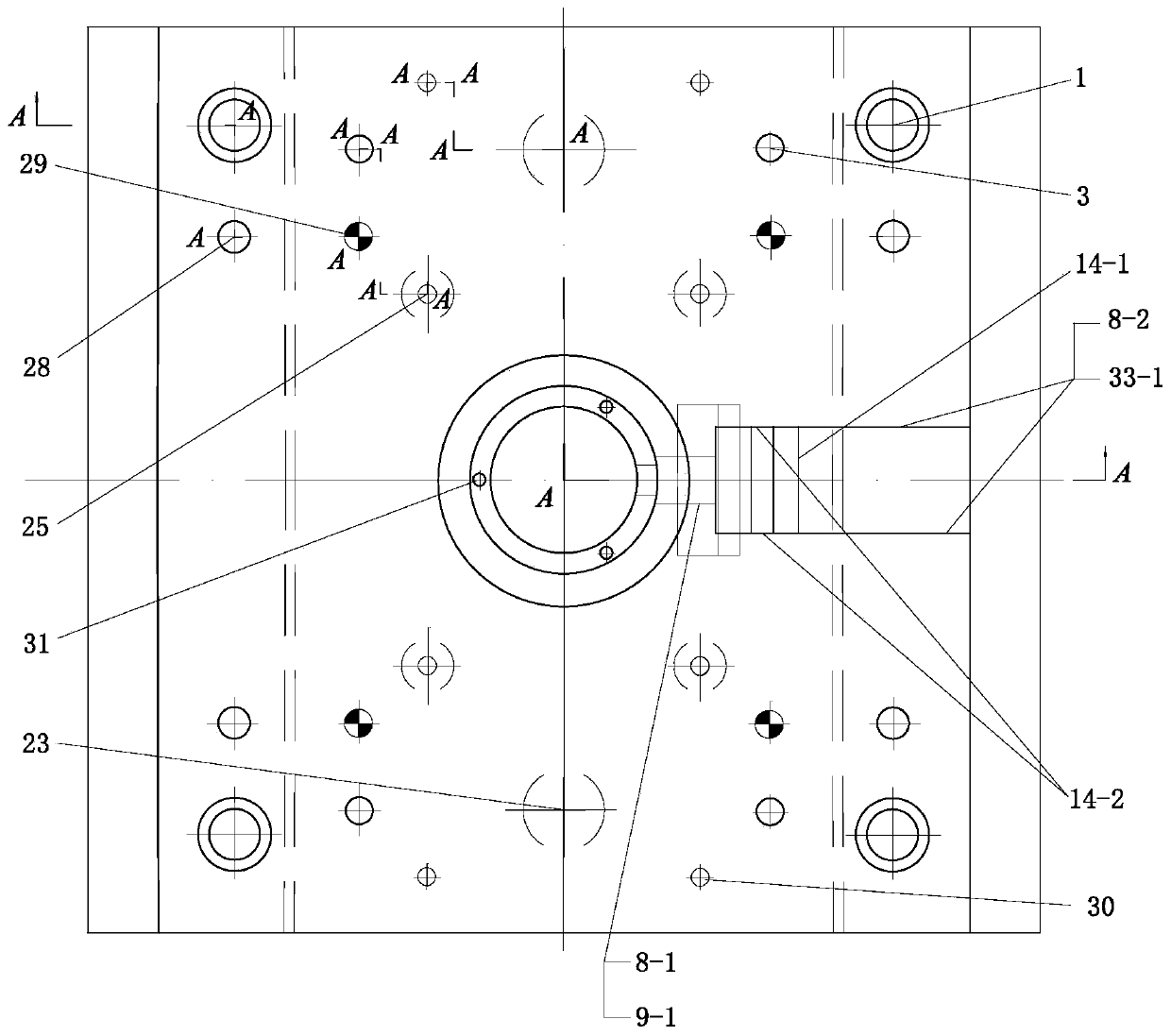

[0044] The lateral core-pulling mechanism of inclined plane pushing and reset proposed by the present invention is as follows: Figure 1-2 shown (where, figure 2It mainly reflects the distribution position of core cavity, inclined push block, lateral core, lateral plate, connecting rod, push rod, reset rod, push plate guide post, guide post, hexagon socket screw, ejector rod of injection machine, etc. ), including formwork, wedge blocks, lateral cores, lateral plates, inclined push blocks, two-stage sequential push-out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com