An electromagnetically controlled exhaust valve connection device

A technology of electromagnetic control and connection device, applied in valve devices, non-mechanically actuated valves, lift valves, etc., can solve problems such as large exhaust resistance of exhaust valves, achieve extended service life, increase impact strength, increase The effect of shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

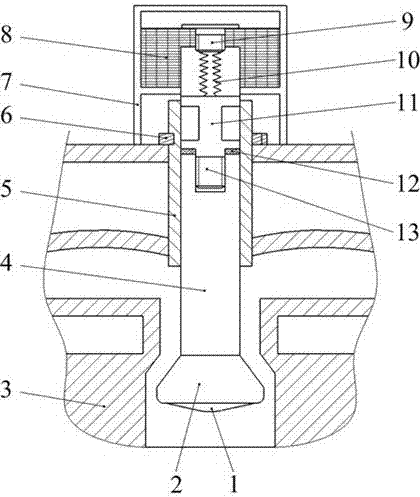

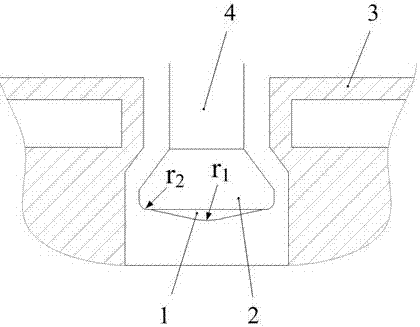

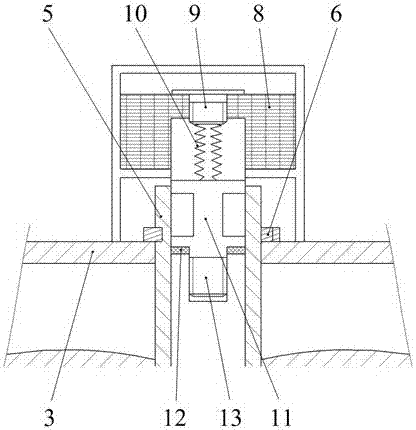

[0020] Such as figure 1 As shown, an electromagnetically controlled exhaust valve connecting device of the present invention mainly includes a valve device and an electromagnetic control device. The electromagnetic control device is installed above the valve device. , snap ring 6 and cylinder block 3, the valve stem 4 and valve head 2 are integrally structured, the upper end of the valve stem 4 is provided with an internal thread blind hole, and the electromagnetic control device is mainly composed of a housing 7, an electromagnetic coil 8, a spring seat 9, a spring 10 and slider 11 form.

[0021] The valve cover 5 is installed outside the valve stem 4, and the valve cover 5 is fixed on the cylinder block 3 by the snap ring 6. The valve cover 5 is made of aluminum alloy. When working, this design realizes the rapid heat dissipation of the valve stem 4, that is, the heat on the valve stem 4 is quickly transferred to the cylinder block 3 through the valve cover 5 by utilizing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com