Method for efficient desulfuration and denitration in coal combustion

A coal combustion and denitrification technology, applied in combustion methods, controlled combustion, separation methods, etc., can solve problems such as affecting manufacturing and inability to accurately detect pore positions, and achieve the effects of reducing corrosion, beneficial to overall stability, and beneficial to desulfurization treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

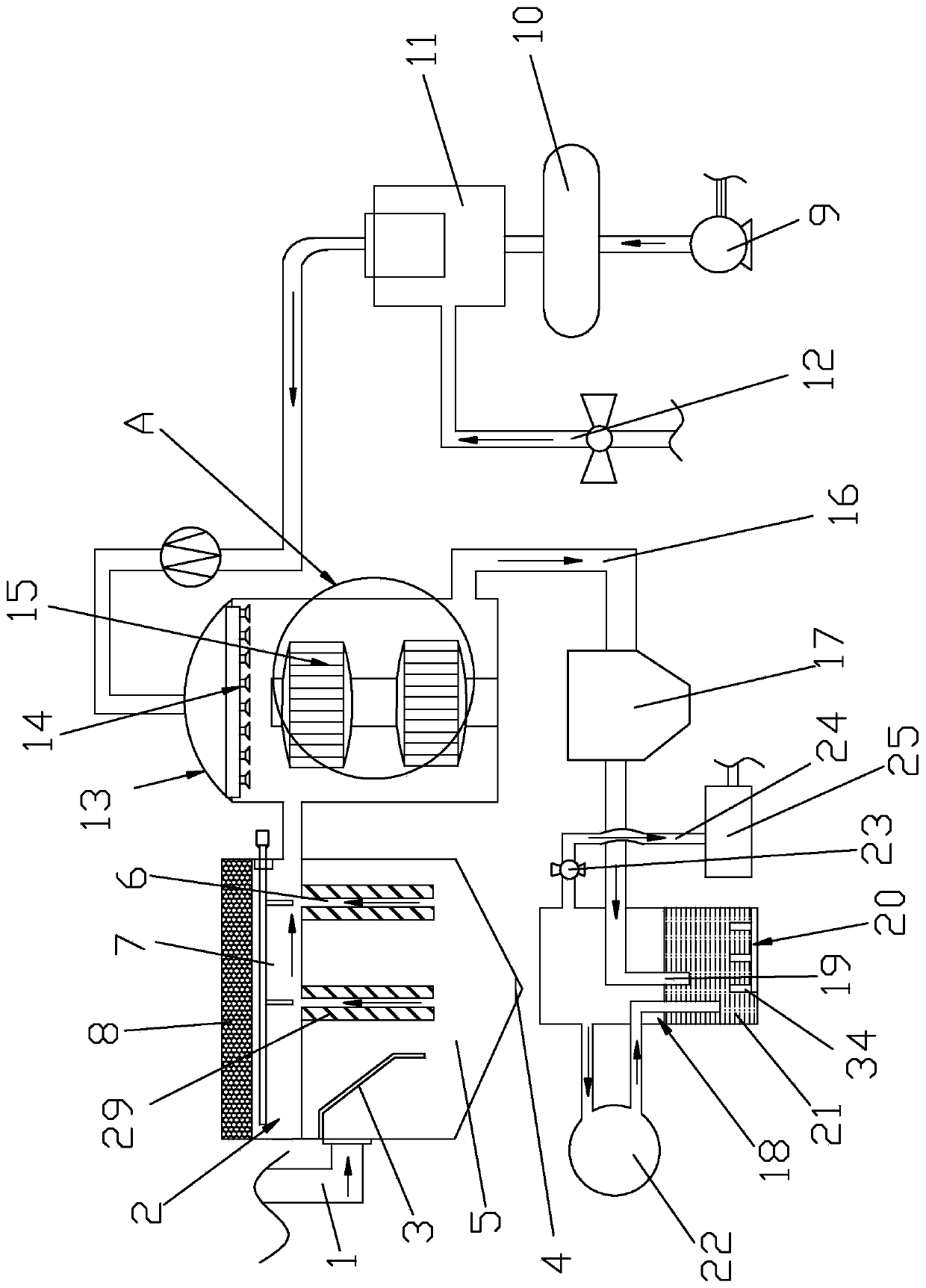

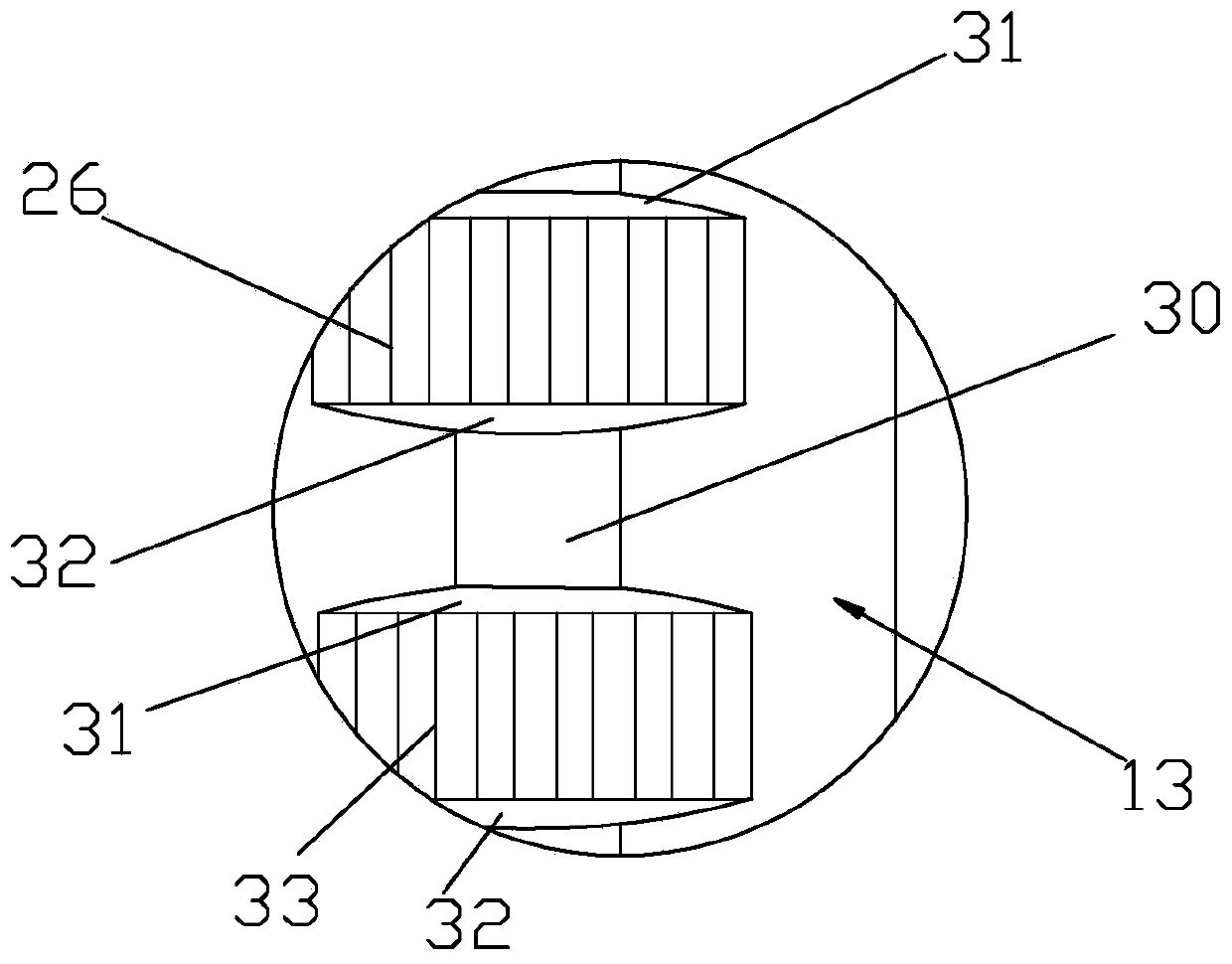

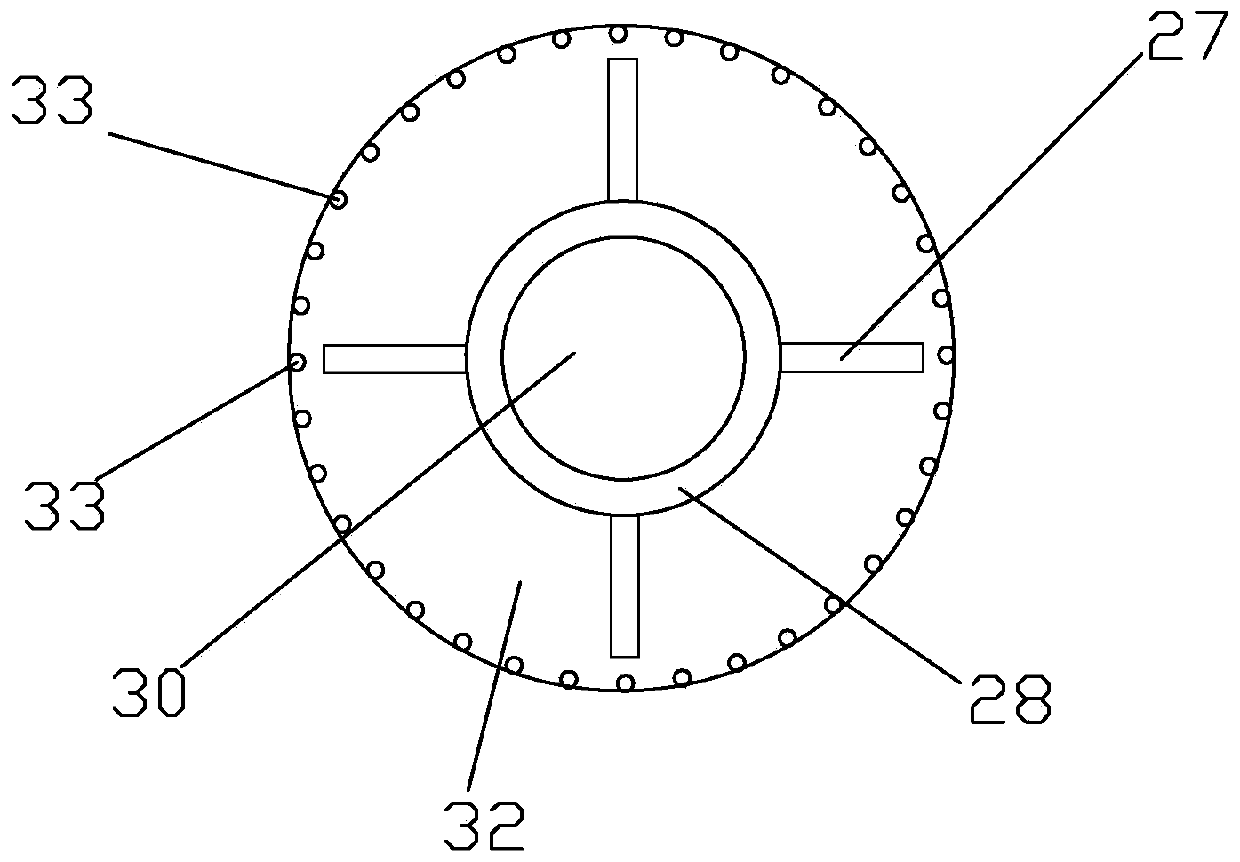

[0043] like Figure 1 to Figure 3 Shown, be the method for a kind of coal combustion efficient desulfurization, denitrification of the present invention, comprise the steps:

[0044] 1) Coal feeding control

[0045] a. Put the burning coal on the coal feeder, adjust the speed of the coal feeder to adjust the amount of coal fed to the coal feeder;

[0046] b. Lead the supplied coal into the heating tank to raise the temperature of the burning coal. The temperature in the heating tank rises to 820-935 °C, and air is introduced into the heating tank, and the excess air coefficient is 0.8-1.2;

[0047] 2) Industrial dust removal

[0048] a. CO in raw material pipe 1 2 The mixed gas is passed into the dust removal tower 2, and the preliminary dust removal is carried out through the dust baffle 3, and the dust enters the dust collection tank 4 after being blocked by the ash baffle 3 under the action of gravity;

[0049] b.CO 2The mixed gas passes through the primary dedusting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com