Manufacturing process of instant tea tablet, and mixing machine applied to process

A production process and technology for instant tablets, which are applied in mixers, manufacturing tools, presses for material forming, etc., can solve the problems of lack of quick tea drinking methods and uneven mixing of raw materials, and achieve simple structure, small volume, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of manufacture technology of tea instant tablet, comprises the following steps:

[0048] (1) Mixing: Take 25% of instant tea powder, 20% of citric acid, 0.9% of sodium carboxymethyl cellulose, and 0.1% of theaflavin in a mixer and fully mix to obtain an acidic mixture;

[0049] (2) Tablet compression: compress the acidic mixture through a tablet machine to obtain acidic tablets;

[0050] (3) Mixing: 25% of instant tea powder, 28% of sodium bicarbonate, 0.9% of sodium carboxymethyl cellulose, and 0.1% of theaflavin are fully mixed in a mixer to obtain an alkaline mixture;

[0051] (4) Tablet compression: compress the alkaline mixture through a tablet machine to obtain alkaline tablets;

[0052] (5) Packaging: The acidic tablet and the alkaline tablet are packaged together at a ratio of 1:1 to obtain tea instant tablets.

Embodiment 2

[0054] A kind of manufacture technology of tea instant tablet, comprises the following steps:

[0055] (1) Mixing: 24% of instant tea powder, 20% of citric acid, 0.9% of sodium carboxymethyl cellulose, and 0.1% of theaflavin are fully mixed in a mixer to obtain an acidic mixture;

[0056] (2) Tablet compression: compress the acidic mixture through a tablet machine to obtain acidic tablets;

[0057] (3) Mixing: 24% of instant tea powder, 30% of sodium bicarbonate, 0.9% of sodium carboxymethyl cellulose, and 0.1% of theaflavin are fully mixed in a mixer to obtain an alkaline mixture;

[0058] (4) Tablet compression: compress the alkaline mixture through a tablet machine to obtain alkaline tablets;

[0059] (5) Packaging: The acidic tablet and the alkaline tablet are packaged together at a ratio of 1:1 to obtain tea instant tablets.

Embodiment 3

[0061] A kind of manufacture technology of tea instant tablet, comprises the following steps:

[0062] (1) Mixing: Take 25% of instant tea powder, 25% of citric acid, 0.9% of sodium carboxymethyl cellulose, and 0.1% of theaflavin in a mixer and fully mix to obtain an acidic mixture;

[0063] (2) Tablet compression: compress the acidic mixture through a tablet machine to obtain acidic tablets;

[0064] (3) Mixing: Take 25% of instant tea powder, 23% of sodium bicarbonate, 0.9% of sodium carboxymethyl cellulose, and 0.1% of theaflavin in a mixer and fully mix to obtain an alkaline mixture;

[0065] (4) Tablet compression: compress the alkaline mixture through a tablet machine to obtain alkaline tablets;

[0066] (5) Packaging: The acidic tablet and the alkaline tablet are packaged together at a ratio of 1:1 to obtain tea instant tablets.

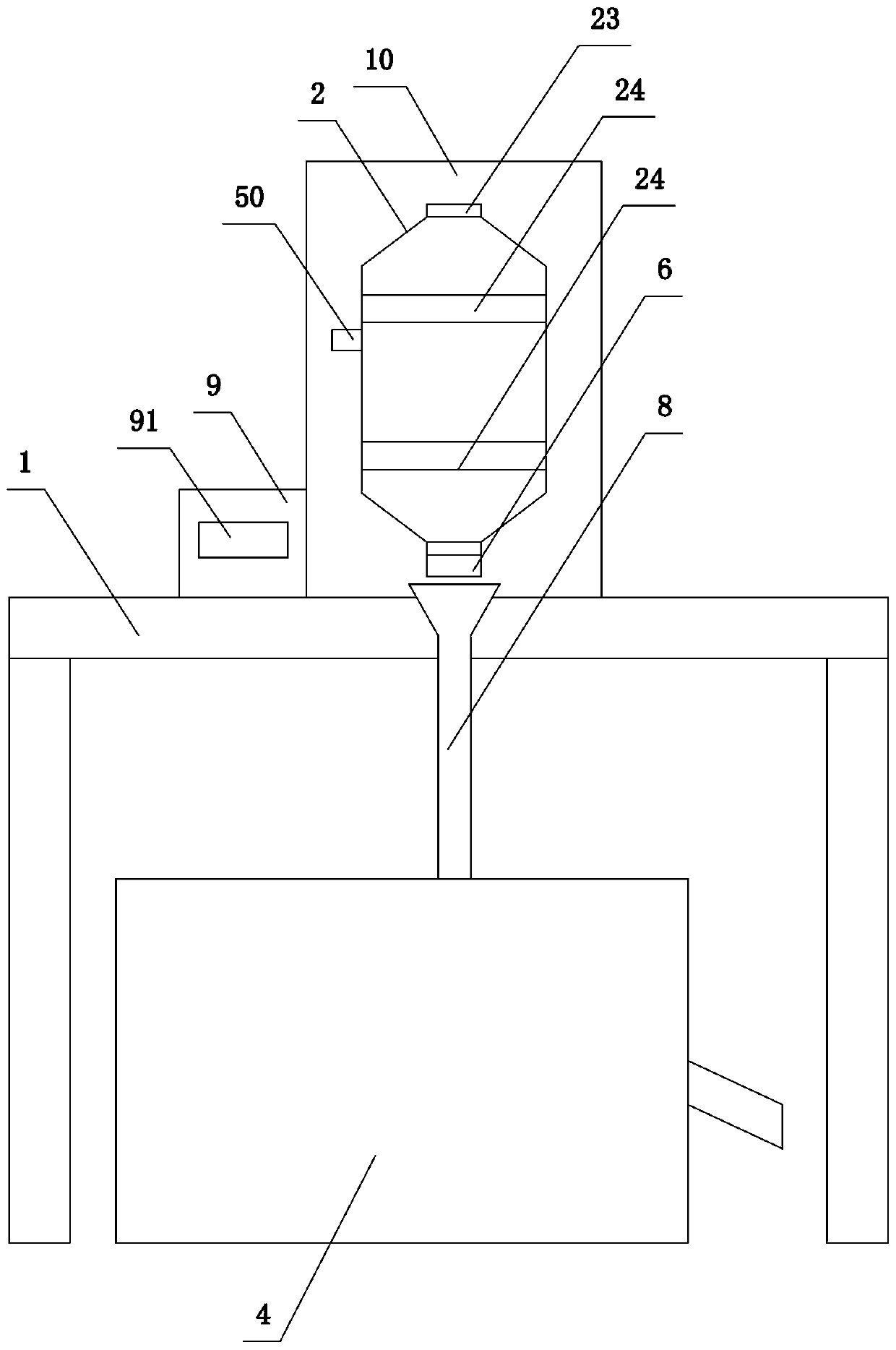

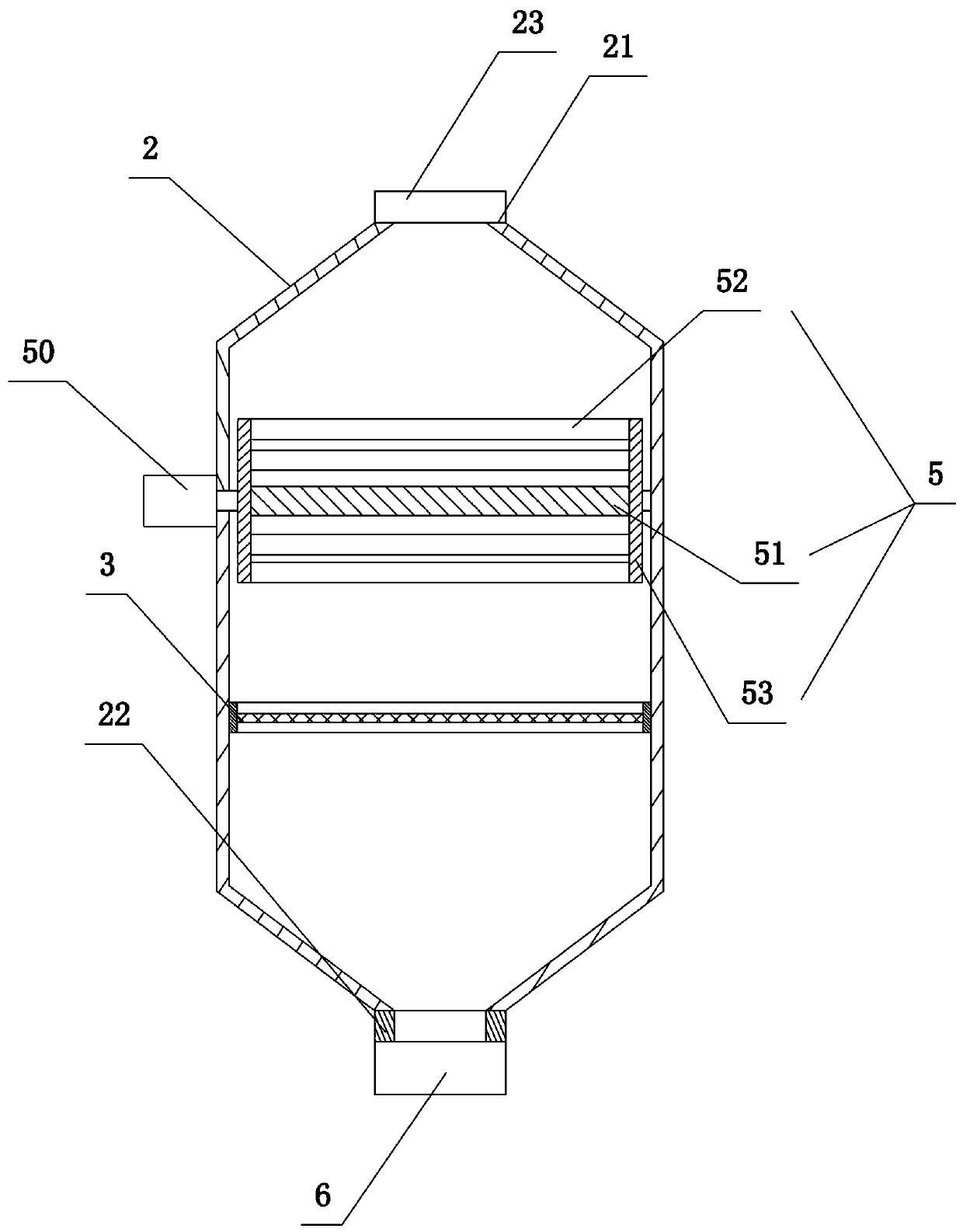

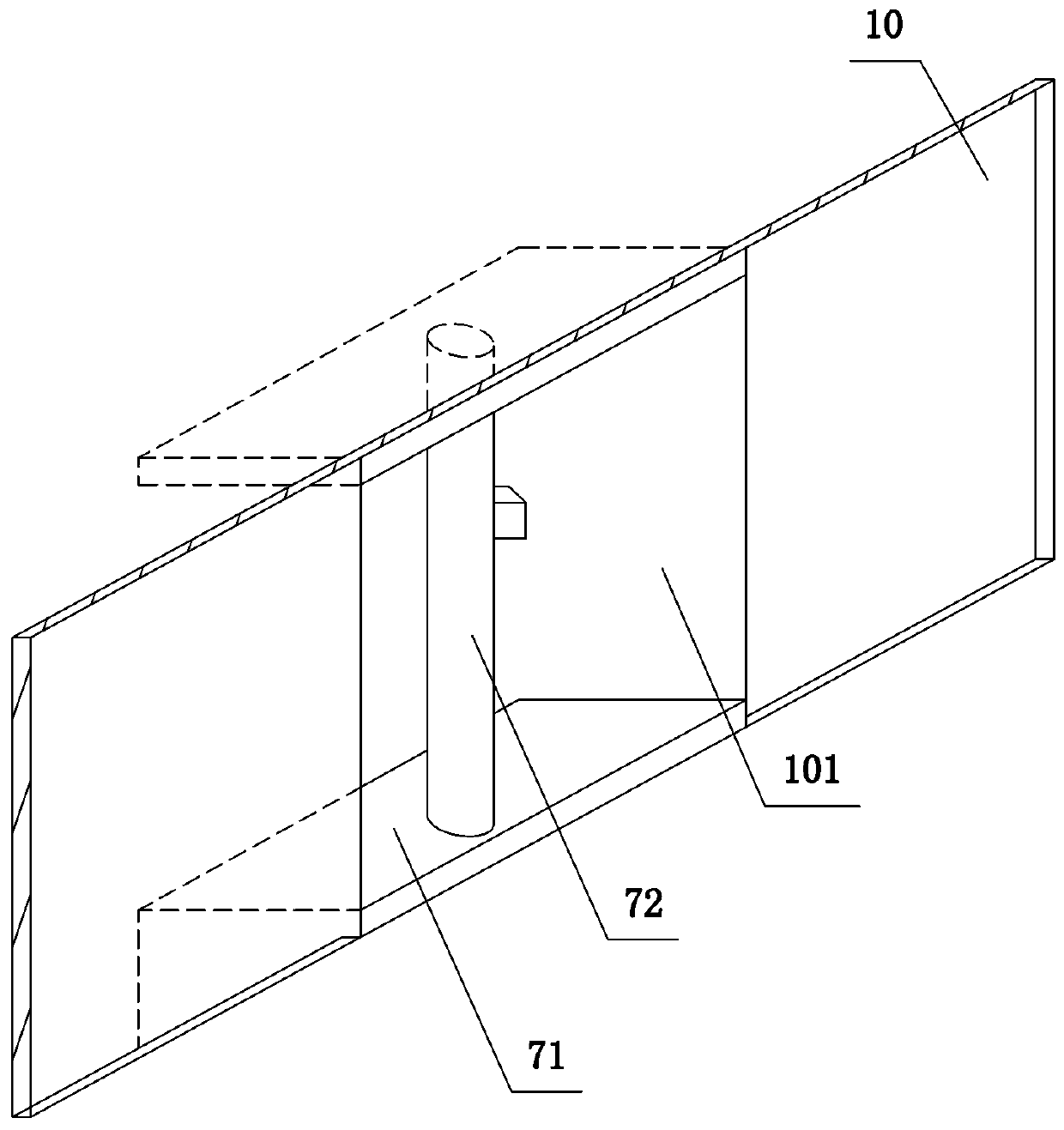

[0067] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 . A mixing machine used in the production process of tea in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com