A kind of negative electrode material of sodium ion battery and preparation method thereof

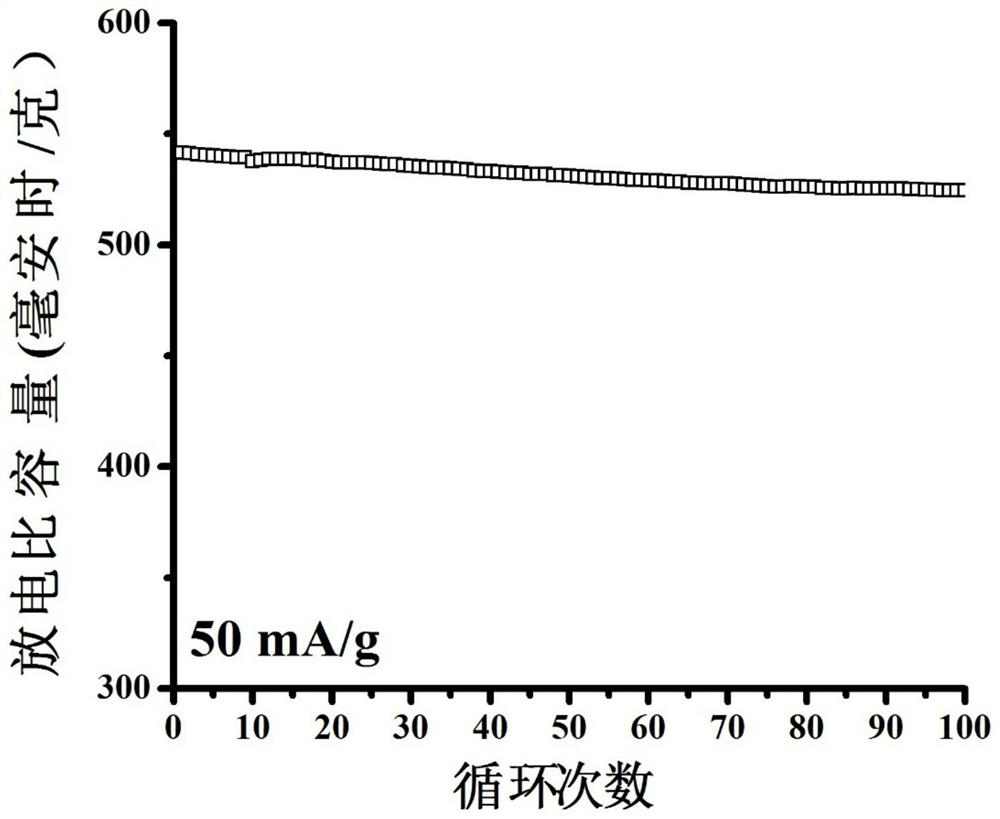

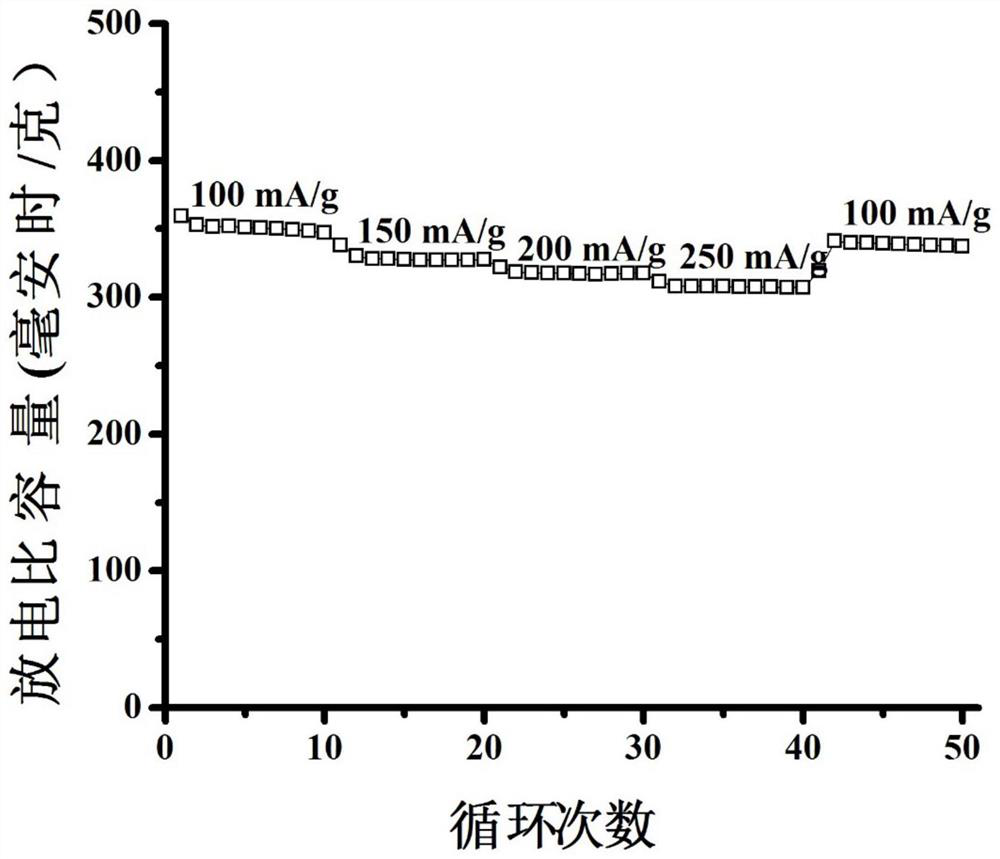

A sodium ion battery and negative electrode material technology, applied in the field of material chemistry, can solve the problems of sodium ion battery negative electrode material volume expansion, easy damage of zinc oxide electrode material, poor cycle stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of reduced graphene oxide fibers:

[0028] Take a commercially available graphene oxide aqueous solution (concentration: 0.5mg / mL), ultrasonicate for 40min, add sodium hydroxide to the uniformly dispersed graphene oxide aqueous solution, the solid-liquid ratio of sodium hydroxide and graphene oxide aqueous solution is 3:100g / mL mL, stirred and reacted at 70°C for 4h, followed by suction filtration to dry the solid powder. The prepared solid powder was placed in N,N-dimethylformamide at a solid-to-liquid ratio of 0.5:100 g / mL to prepare a spinning stock solution, and then the graphene oxide fiber was prepared by wet spinning. Place the prepared graphene oxide fiber in a reaction vessel, add hydrazine hydrate dropwise to it, the amount of hydrazine hydrate is added dropwise with reference to the ratio of 0.3g graphene oxide fiber: 0.1mL hydrazine hydrate, and place it in a constant temperature furnace , heat preservation at 100°C for 8 hours to obtain red...

Embodiment 2

[0034] (1) Preparation of reduced graphene oxide fibers:

[0035] Take commercially available graphene oxide aqueous solution (concentration is 0.1mg / mL), ultrasonic 30min, add sodium hydroxide to the uniformly dispersed graphene oxide aqueous solution, the solid-liquid ratio of sodium hydroxide and graphene oxide aqueous solution is 2:100g / mL mL, stirred and reacted at 60°C for 3h, followed by suction filtration to dry the solid powder. The prepared solid powder was placed in N,N-dimethylformamide at a solid-to-liquid ratio of 0.1:100 g / mL to prepare a spinning stock solution, and then the graphene oxide fiber was prepared by wet spinning. Place the prepared graphene oxide fiber in a reaction vessel, add hydrazine hydrate dropwise, the amount of hydrazine hydrate is added dropwise with reference to the ratio of 0.1g graphene oxide fiber: 0.1mL hydrazine hydrate, and place it in a constant temperature furnace , 90 ° C for 6 h to react to obtain reduced graphene oxide fibers. ...

Embodiment 3

[0041] (1) Preparation of reduced graphene oxide fibers:

[0042] Take a commercially available graphene oxide aqueous solution (concentration: 2mg / mL), ultrasonicate for 60min, add sodium hydroxide to the uniformly dispersed graphene oxide aqueous solution, the solid-liquid ratio of sodium hydroxide to graphene oxide aqueous solution is 5:100g / mL , Stir the reaction at 80° C. for 5 h, and then perform suction filtration to dry the solid powder. The prepared solid powder was placed in N,N-dimethylformamide at a solid-to-liquid ratio of 2:100 g / mL to prepare a spinning stock solution, and then the graphene oxide fiber was prepared by wet spinning. Place the prepared graphene oxide fiber in a reaction vessel, add hydrazine hydrate dropwise, the amount of hydrazine hydrate is added dropwise with reference to the ratio of 0.5g graphene oxide fiber: 0.1mL hydrazine hydrate, and place it in a constant temperature furnace , 120 ° C for 12 h to react to obtain reduced graphene oxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com