Determination of activated sludge concentration

A measurement method and activated sludge technology, applied in chemical method analysis, chemical analysis by titration method, measuring device, etc., can solve problems such as inaccurate test results, achieve low cost, high repeatability, and low detection cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

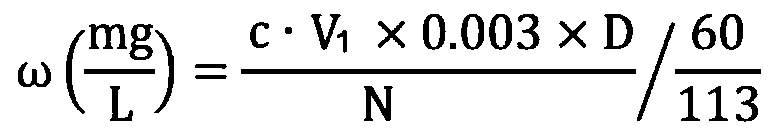

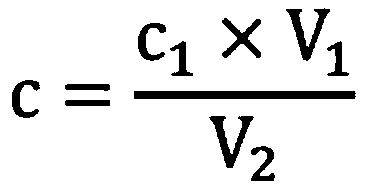

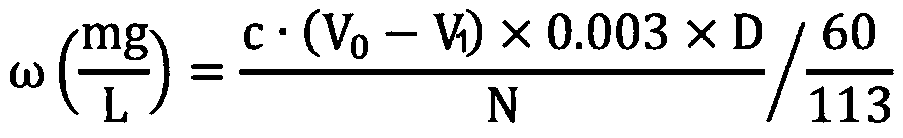

[0039] (1) Calibration of ferrous sulfate standard solution

[0040] Before each use, 0.2mol / L ferrous sulfate standard solution needs to be calibrated with 0.1mol / potassium dichromate standard solution. Draw 0.1mol / L potassium dichromate standard solution 20mL and 150mL Erlenmeyer flask, add concentrated sulfuric acid 3~5mL and 2~3 drops of phenanthroline indicator, and titrate with ferrous sulfate standard solution. According to the consumption of ferrous sulfate standard solution titration, the following formula is calculated:

[0041]

[0042] c 1 —concentration of potassium dichromate standard solution (mol / L); V 1 - Draw the volume of potassium dichromate standard solution (mL);

[0043] V 2 ——The volume of ferrous sulfate standard solution consumed during titration (mL).

[0044] (2) Digestion reaction.

[0045] Take 1mL of activated sludge in a 100mL volumetric flask and dilute to the mark with distilled water. Take 1 mL of the sample in the volumetric flask ...

Embodiment 2

[0060] The difference with Example 1 is: no blank test is carried out.

[0061] The calculated concentration of activated sludge is 5.75g / L, and the accuracy of the test result is 99.65%.

Embodiment 3

[0063] The difference with Example 1 is: the concentration of iron sulfate standard solution is 0.192mol / L.

[0064] The calculated concentration of activated sludge is 5.70g / L, and the accuracy of the test result is 99.48%.

[0065] From the above description, it can be seen that the above-mentioned embodiments of the present invention have achieved the following technical effects:

[0066] Compared with dry sludge as the measurement object, this application directly takes the mud-water mixture containing activated sludge as the measurement object. This can save the step of drying the sludge and simplify the measurement process. At the same time, the above-mentioned test method can eliminate the interference of volatile and easily sublimable inorganic substances on the measurement results of activated sludge concentration and organic matter content, so that the measurement results are accurate, the properties of activated sludge can be accurately characterized, and the norma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com