Winching potential energy real-time recycling system and control method thereof

A potential energy recovery and potential energy technology, applied in the field of hoist hydraulics, can solve problems such as restricting application, inconvenient construction machinery structure design, and difficulty in hoisting down at a constant speed, achieving obvious energy-saving effect, simple and reliable pipeline connection, and excellent energy-saving effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

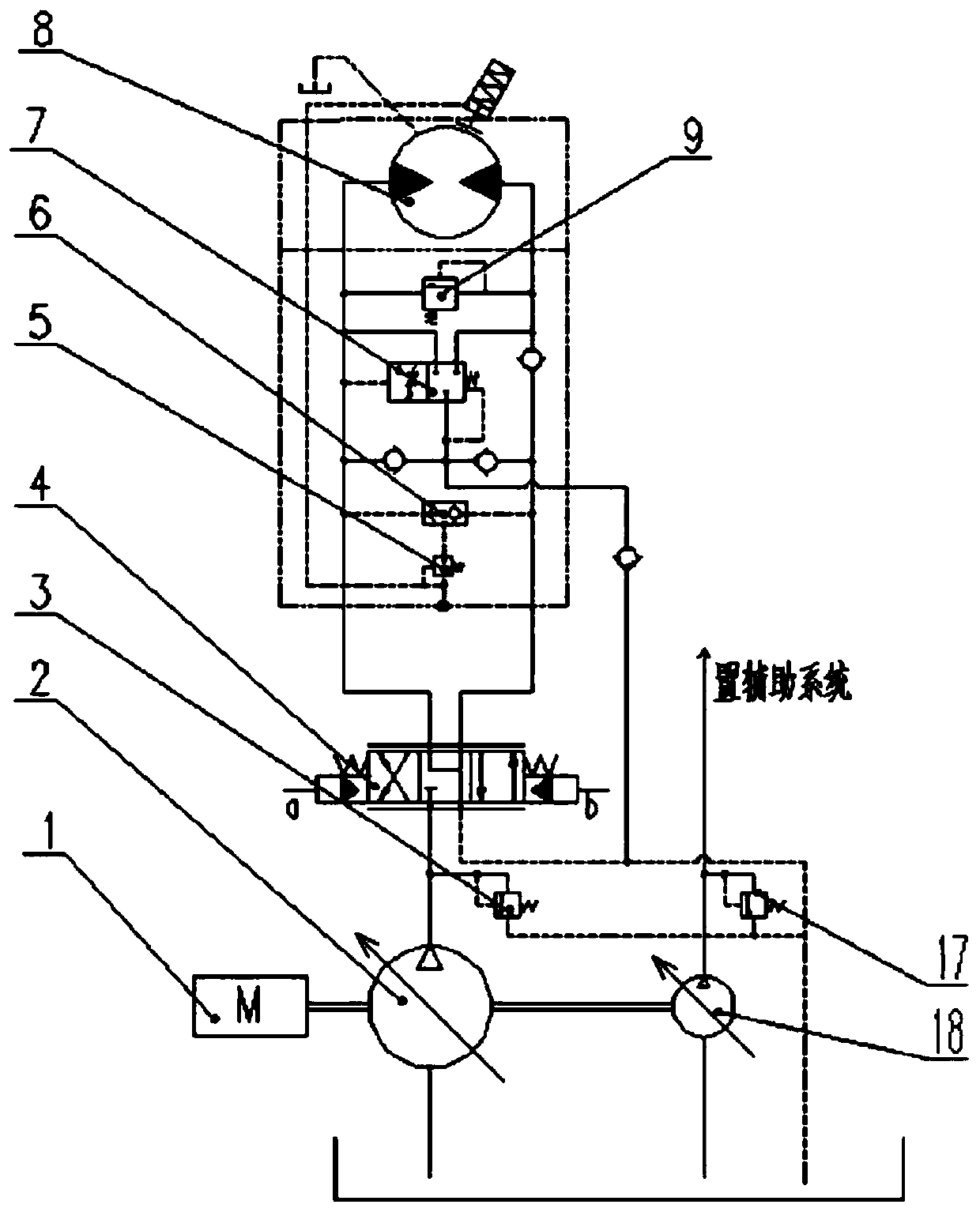

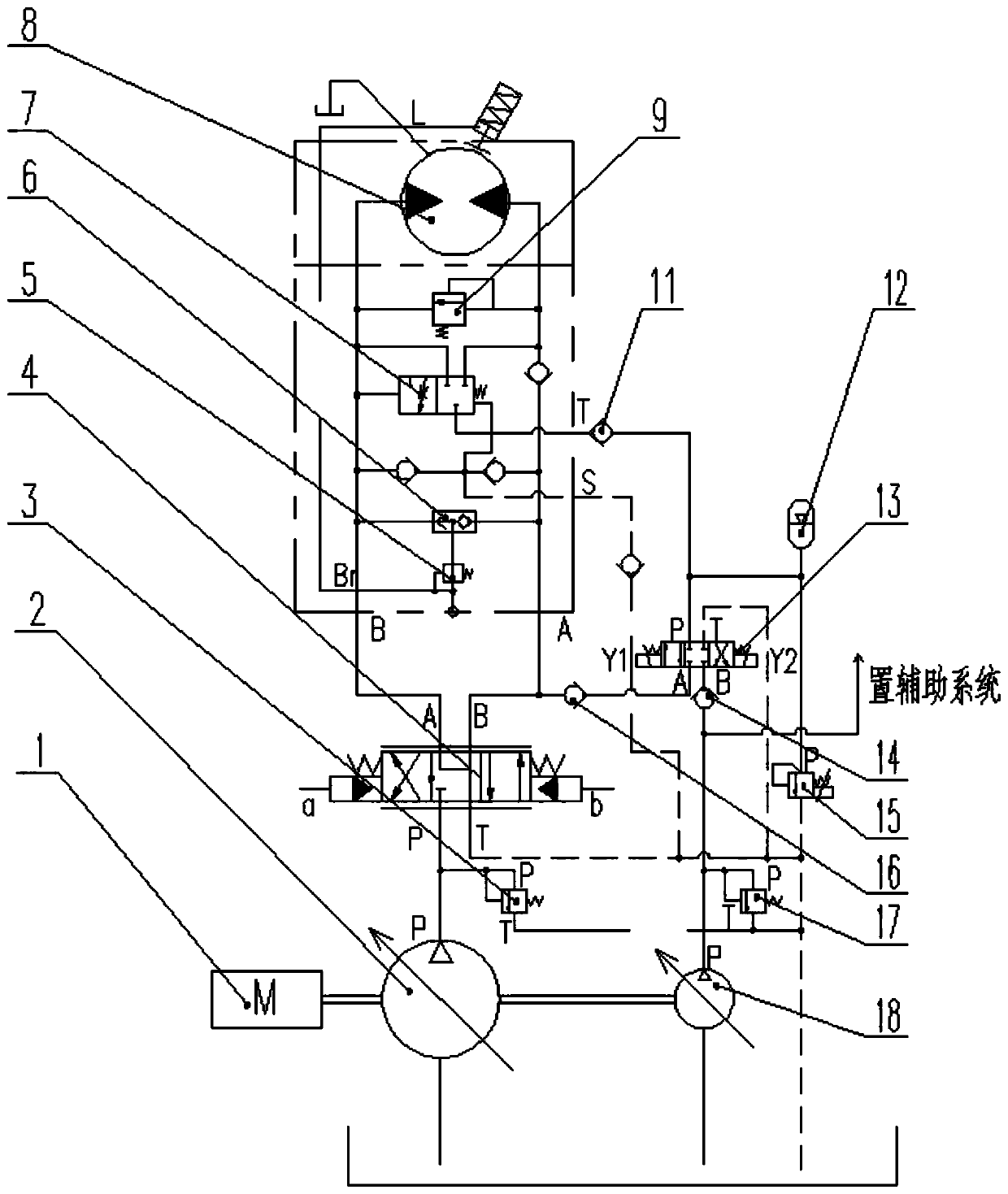

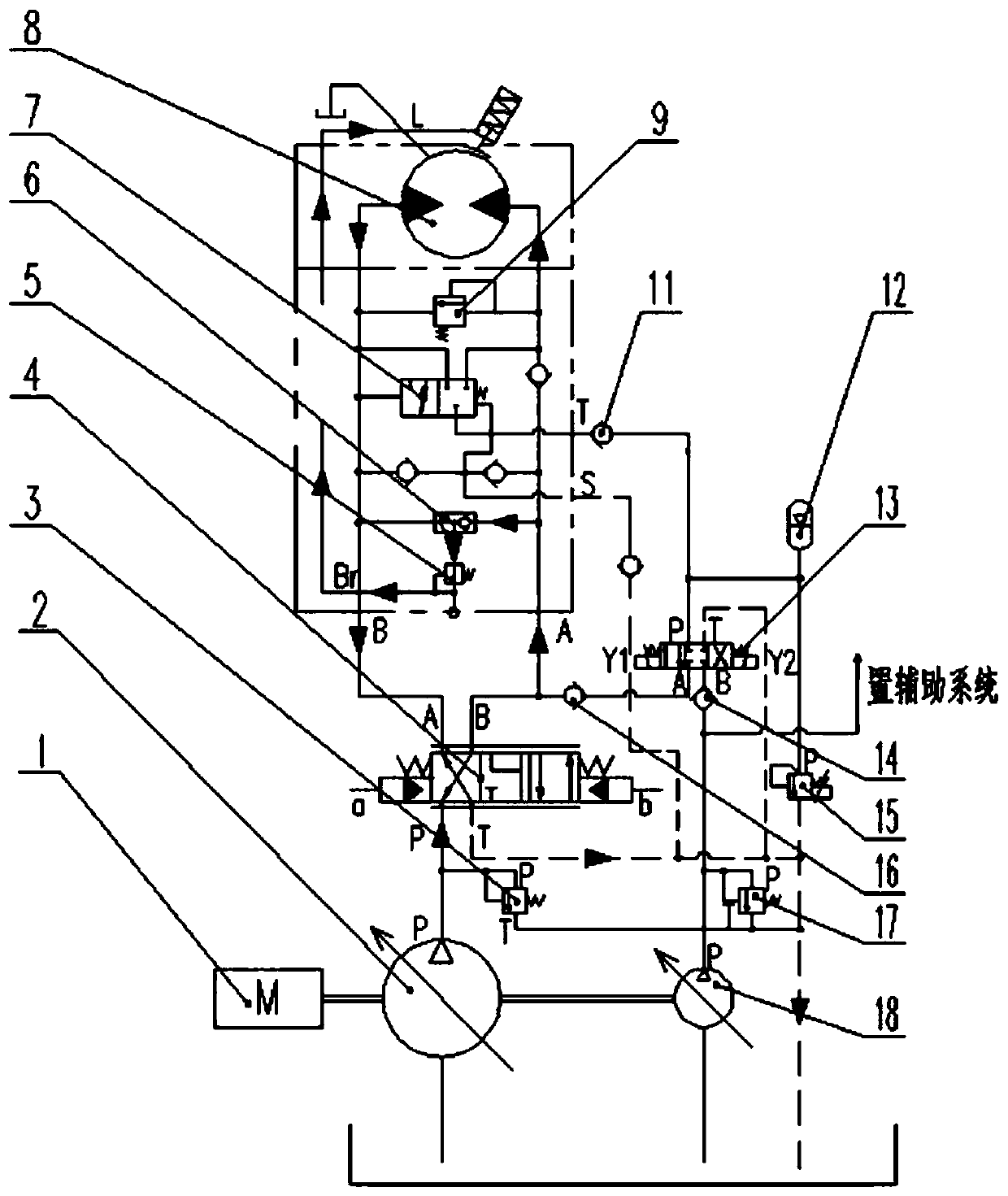

[0042] see figure 2 , the hoisting potential energy real-time recovery and utilization system in the illustration is a specific embodiment of the present invention, including an engine 1, a main pump 2, a main pump overflow valve 3, a reversing main valve 4, a pressure reducing valve 5, a shuttle valve 6, Pilot balance valve 7, winch motor 8, overload protection valve 9, check valve 11 / 13 / 16, accumulator 12, potential energy recovery reversing valve 13, electric proportional relief valve 15, auxiliary pump relief valve 17 And auxiliary pump 18.

[0043] Among them, the main pump 2 and the auxiliary pump 18 are coaxially driven by the engine 1. The coaxial referred to here refers to the synchronous transmission of the main pump 2 and the auxiliary pump 18 through the output shaft of the engine 1, wherein the main pump 2 controls the winch motor 8 The auxiliary pump 18 is used as other hydraulic auxiliary system to provide pressure oil. The main pump 2 and the auxiliary pump 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com