In situ modification method of electronic grade spherical packing

A spherical filler and in-situ modification technology, which is applied in the field of in-situ modification of electronic grade spherical fillers, can solve the problems of spherical fillers that cannot be mechanically ground, spherical particle defects, expensive materials, etc., and achieve compatibility and binding force Excellent, excellent hydrophobic performance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

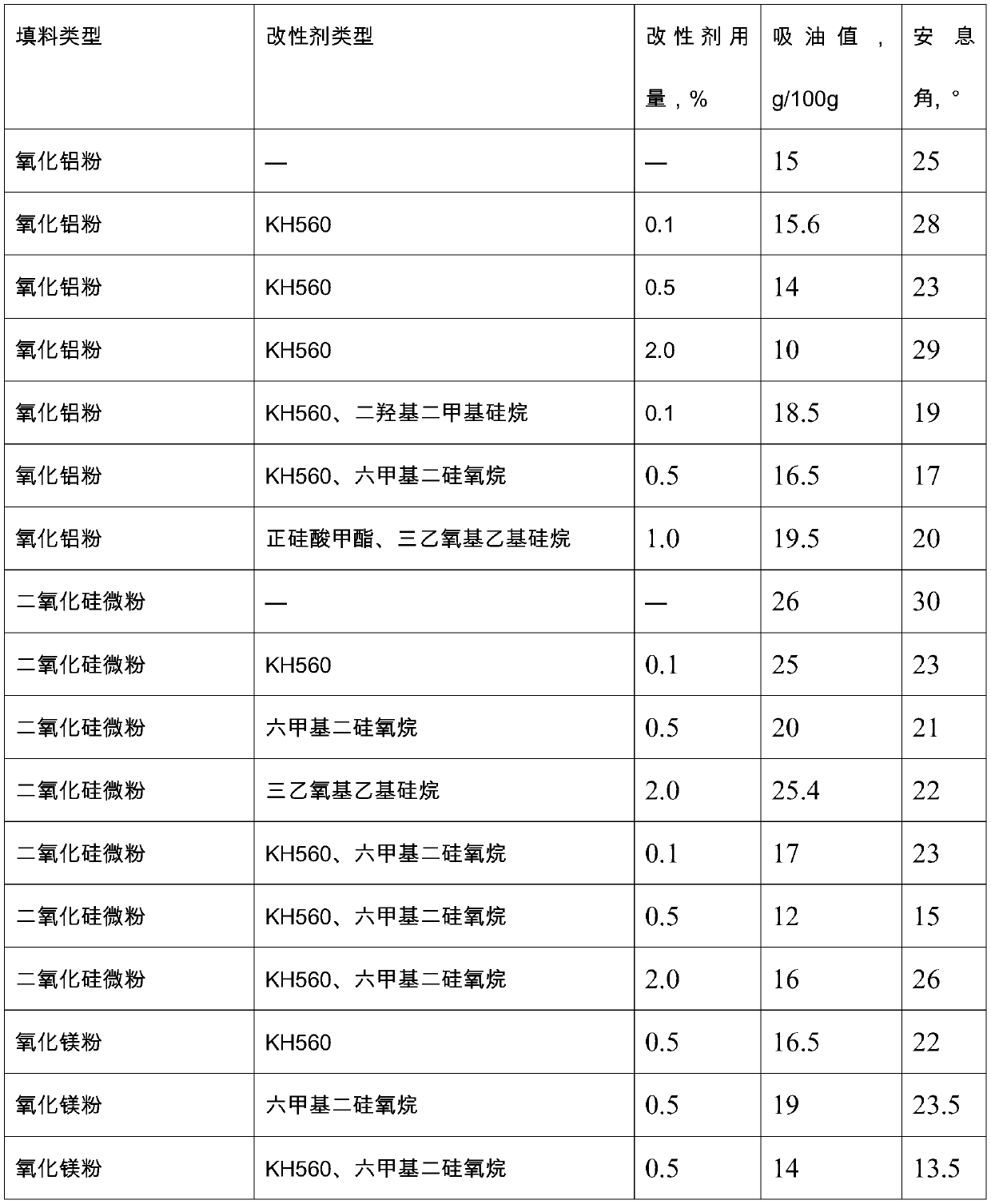

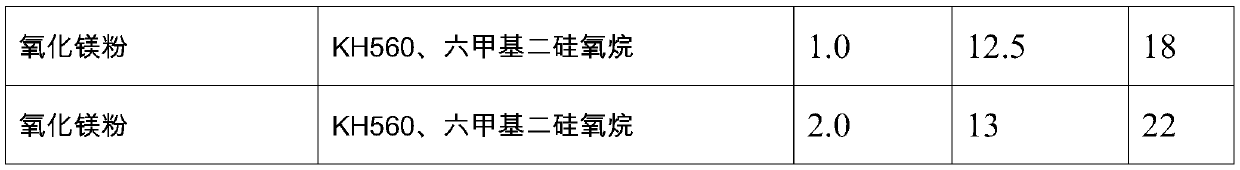

Examples

Embodiment 1

[0018] Example 1, an in-situ modification method of electronic grade spherical fillers, the method selects spherical fillers with an average particle diameter D50 between 0.01 μm and 60 μm, and introduces the spherical fillers into one or more of oxygen, air or nitrogen. Several kinds are used as the carrier gas, in a reaction vessel in which natural gas is the combustible gas and oxygen is the combustion aid, the spheroidization is ignited and cooled after the spheroidization is completed. When cooling to 80°C-150°C, add coupling The coupling agent is added in an amount of 0.1% of the total weight of the spherical filler, thereby preparing the in-situ modified spherical filler.

Embodiment 2

[0019] Example 2, an in-situ modification method of electronic-grade spherical fillers, the method selects spherical fillers with an average particle diameter D50 between 0.01 μm and 60 μm, and introduces the spherical fillers into one or more of oxygen, air or nitrogen. Several kinds are used as the carrier gas, in a reaction vessel in which natural gas is the combustible gas and oxygen is the combustion aid, the spheroidization is ignited and cooled after the spheroidization is completed. When cooling to 80°C-150°C, add coupling agent, and the addition of coupling agent accounts for 2% of the total weight of the spherical filler, thereby preparing the in-situ modified spherical filler.

Embodiment 3

[0020] Example 3, an in-situ modification method of electronic grade spherical fillers, the method selects spherical fillers with an average particle diameter D50 between 0.01 μm and 60 μm, and introduces the spherical fillers into one of oxygen, air or nitrogen or Several kinds are used as the carrier gas, in a reaction vessel in which natural gas is the combustible gas and oxygen is the combustion aid, the spheroidization is ignited and cooled after the spheroidization is completed. When cooling to 80°C-150°C, add coupling agent, and the addition amount of the coupling agent accounts for 1% of the total weight of the spherical filler, thereby preparing the in-situ modified spherical filler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com