A heteronuclear polymetallic organic framework material and its preparation and application in denitrification and mercury removal

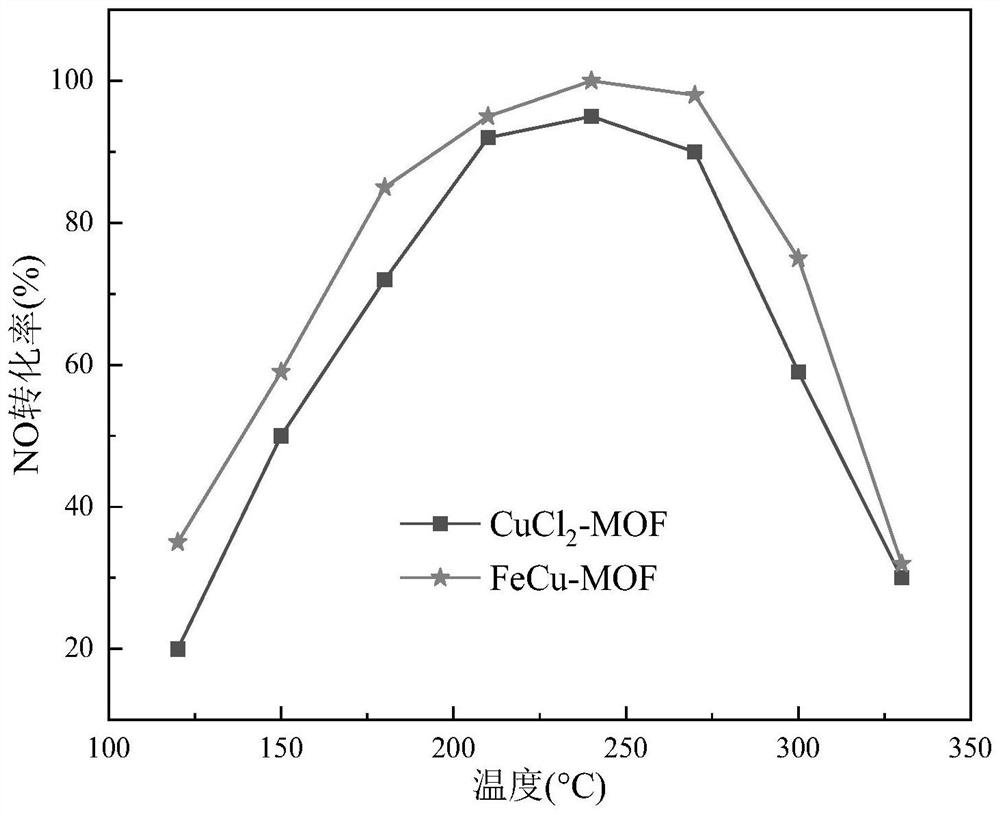

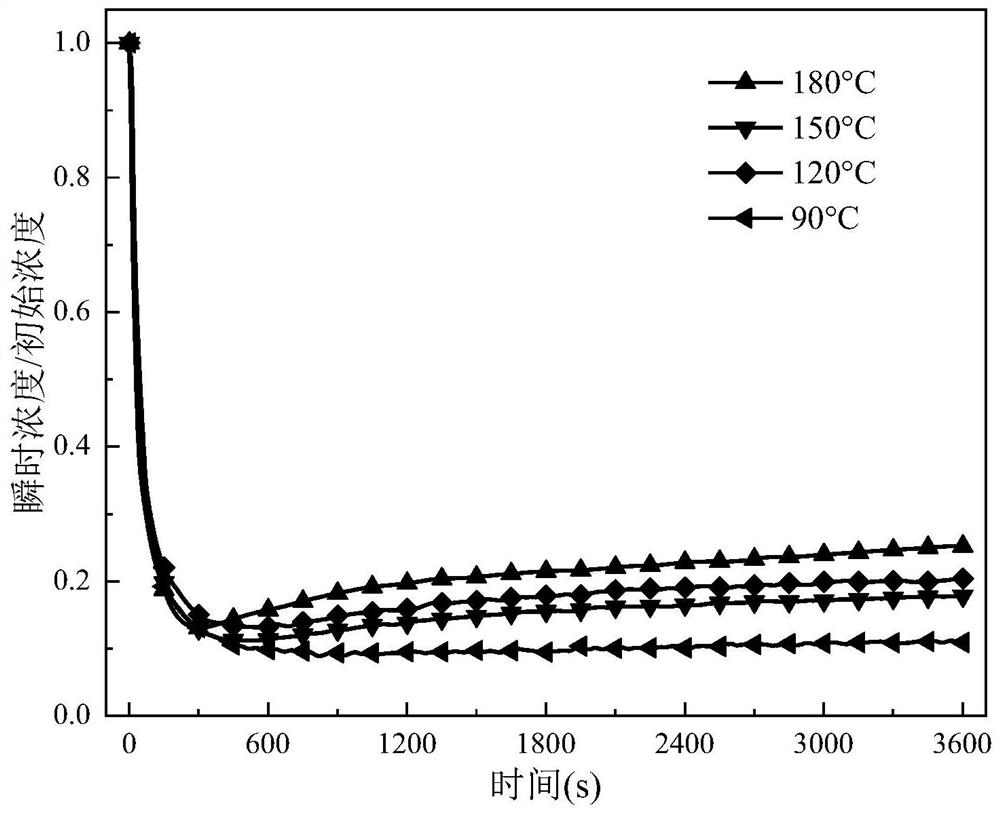

An organic framework and multi-metal technology, applied in the field of flue gas pollutant control, can solve the problems of poor water vapor poisoning ability, high catalytic temperature, and low catalytic efficiency, and achieve short production cycle, simple preparation method, low-temperature denitrification and mercury removal high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

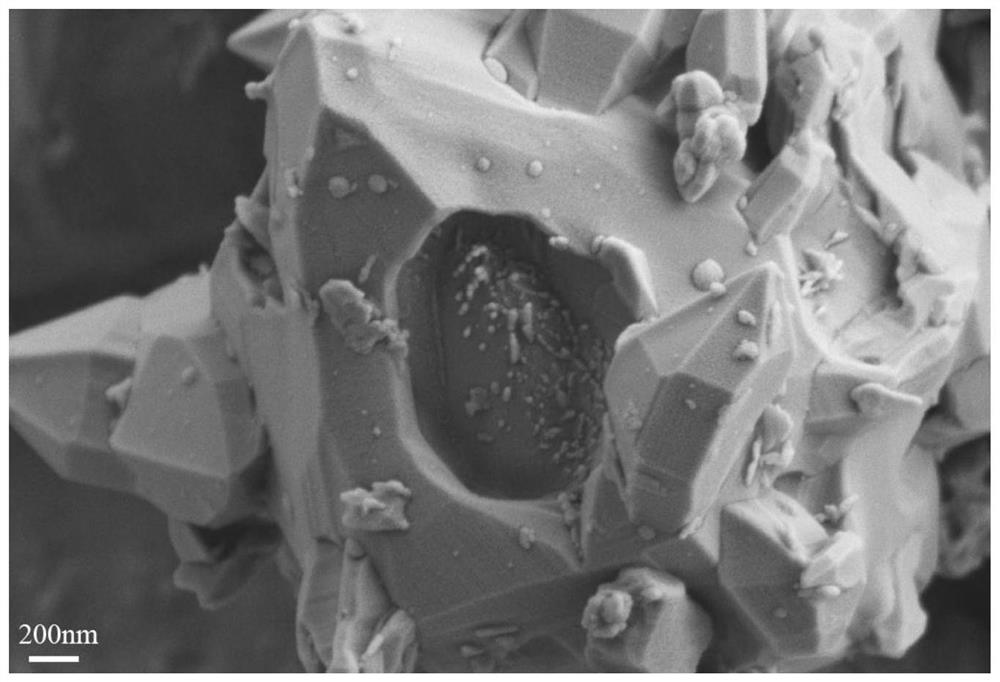

[0029]A method of preparation of a heterical multi-metal organic skeleton material comprising the step of: dissolving a certain amount of transition metal salt 1 in deionized water or anhydrous methanol, preparing solution I, and a certain amount of transition metal salt material II is dissolved in deionized water or anhydrous methanol, at least a halide of a transition metal salt, a quantity of 1,3,5-phenyltriphenic acid (H3BTC) or benzoic acid (H2BTC was dissolved in anhydrous ethanol with N, N-dimethylformamide (DMF) mixed solution (mixed solution volume ratio 1: 1) to prepare solution III. The solution I, II was transferred to a reaction kettle containing a solution II for a mixed solution IV after a certain ratio, and the mixed solution IV was subjected to ultrasound or microwave treatment for a certain period of time, and was placed in an oven or reaction furnace to generate crystallization. Get the initial sample of the powder. Solvents such as water, anhydrous methanol or an...

Embodiment 1

[0038](1) Put a certain amount of Cu (NO3)2· 3h2O Solution I is prepared in deionized water at a mass volume ratio of 1:30, and a quantity of FeCl3· 6h2O Preparation of solution II in anhydrous methanol in an anhydrous methanol in anhydrous metallogenic volume ratio in anhydrous methane (h).3BTC) was dissolved in anhydrous ethanol with a mixed solution of anhydrous ethanol (mixed solution volume ratio 1: 1) in a molar ratio of 1:10. Solution III. The solution I, II was transferred to the reactor of the copper iron molar ratio of 0.5, and the mixed solution IV was prepared in a reaction kettle containing a solution III, and the mixed solution IV was 100 kHz / 600 W ultrasonic treatment for 20 min, and placed in an oven or reaction furnace 120 ° C for drying treatment, producing the initial sample of the powder. Water was washed, purified, dried to give initial samples, purified, and dried to give the initial heterodal multi-metal organic skeleton material (MOFS). The initial hetero-m...

Embodiment 2

[0042](1) Put a certain amount of Cucl2· 2h2O Solution I is prepared in deionized water in a mass volume ratio of 1:50, and a quantity of MN (NO3)2· 4h2O Preparation of solution II in anhydrous methanol in anhydrous methanol in anhydrous metallocetic volume ratio in anhydrous methane (h).3BTC) was dissolved in anhydrous ethanol and a mixed solution of anhydrous ethanol and DMF in a mixed solution of 1: 2. The solution I, II was transferred to the proportion of copper manganese mole ratio 0.8, and the mixed solution IV was transferred to a reaction kettle containing a solution III, and the mixed solution IV was subjected to 1000 MHz / 800W microwave treatment for 60 min, and placed in an oven or reactive furnace 120 ° C for drying treatment, producing the initial sample of the powder. Water was washed, purified, dried to give initial samples, purified, and dried to give the initial heterodal multi-metal organic skeleton material (MOFS). The obtained initial heteroa multi-metal MOFS w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com