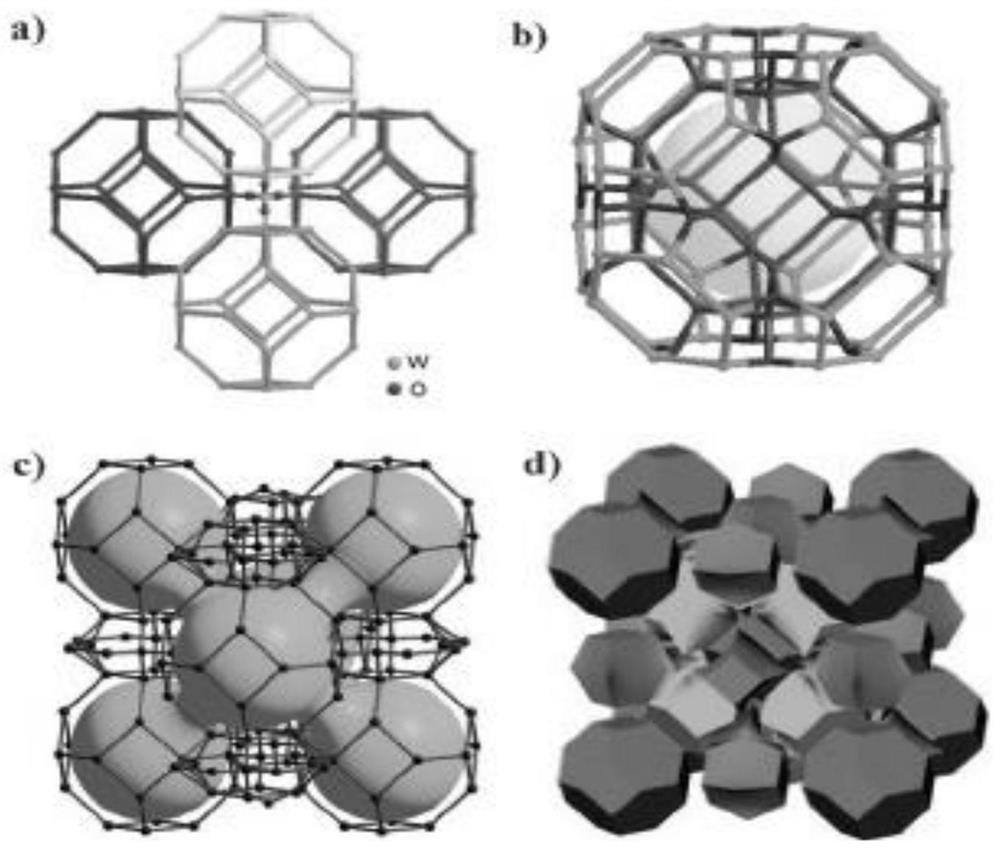

Macro-scale preparation and morphology control method of hybrid zeolite imidazole framework materials

A technology of zeolite imidazole and framework materials, which is applied in the field of macro-scale preparation and shape control of hybrid zeolite imidazole framework materials, can solve the problems of inability to scale up synthesis and long time, and achieve the convenience of large-scale production, shortening of reaction time, and synthesis The process requires simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

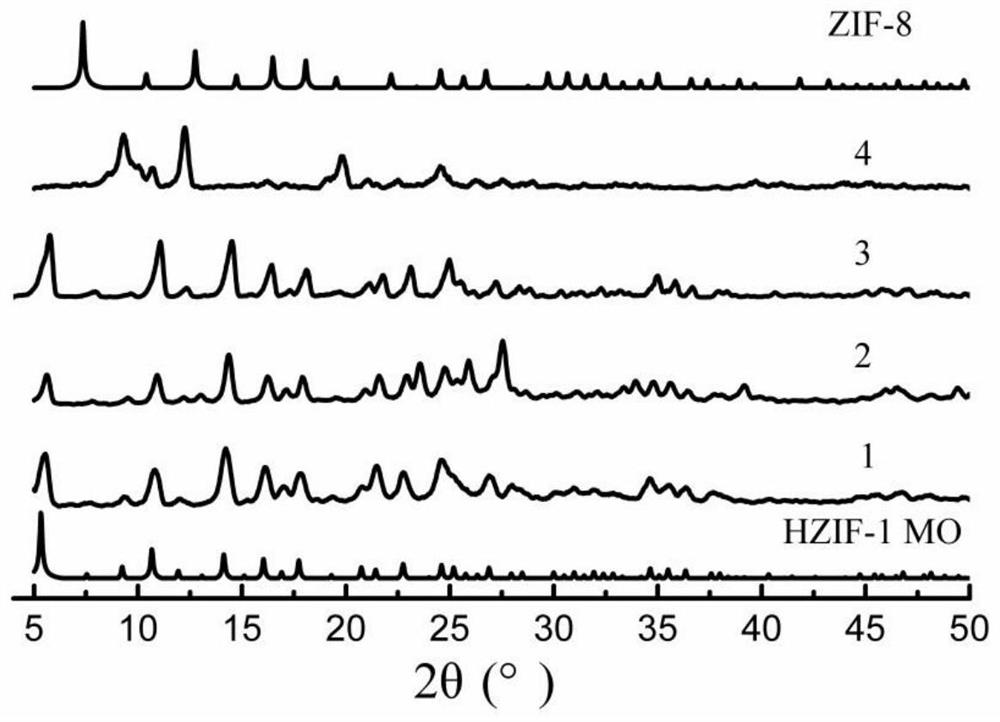

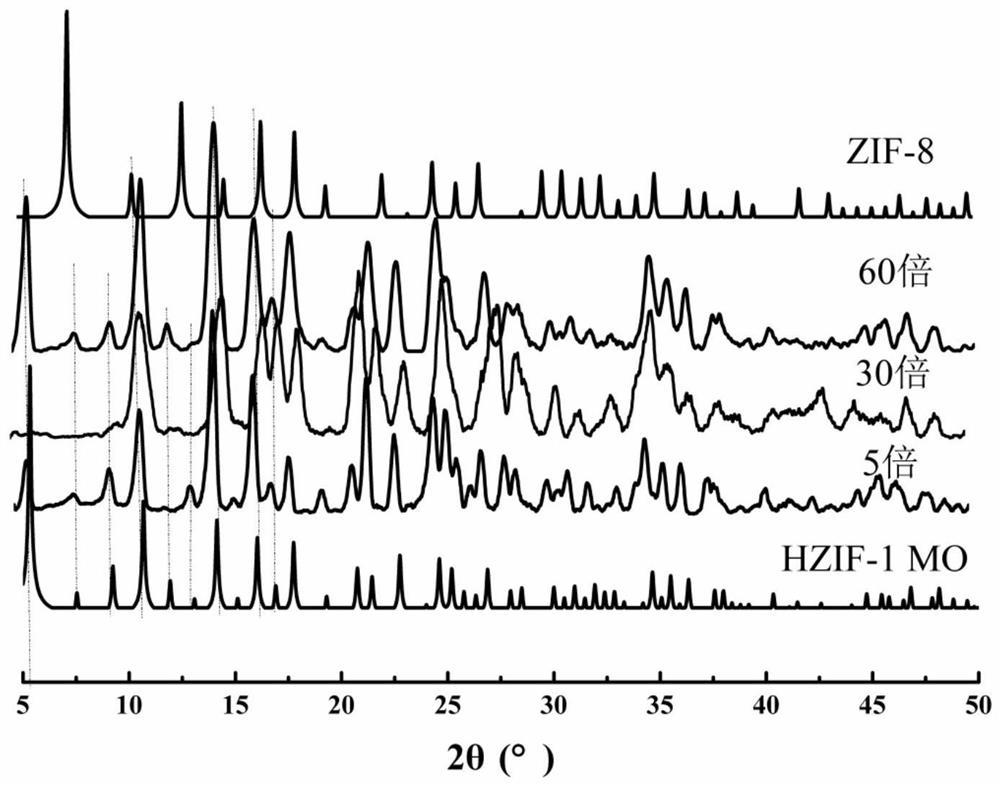

Embodiment 1

[0054] Heating and stirring: ①Zn(CH 3 COO) 2 2H 2 O (0.176g, 0.8mmol), 2-mim (0.098g, 1.2mmol), H 2 MoO 4 (0.03g, 0.2mmol), put the raw material in a round bottom flask, add DMF, reflux and stir at a temperature of 160°C for 2 hours, filter the obtained product, wash the separated solid with water, and put it in an oven at 80°C Dry to obtain HZIF-1Mo crystals.

[0055] ②Zn(CH 3 COO) 2 2H 2 O (0.176g, 0.8mmol), 2-mim (0.098g, 1.2mmol), H 2 MoO 4 (0.03g, 0.2mmol), put the raw material in a round bottom flask, add methanol, reflux and stir at a temperature of 60°C for 2 hours, filter the obtained product, wash the separated solid with water, and put it in an oven at 80°C Dry to obtain HZIF-1Mo crystals.

Embodiment 2

[0057] Ultrasonic response: Zn(CH 3 COO) 2 2H 2 O (0.180g, 0.8mmol), 2-mim (0.096g, 1.2mmol), H 2 MoO 4 (0.028g, 0.2mmol), put the raw materials in a beaker, add DMF, and sonicate in an ultrasonic instrument for 4 hours, filter the obtained product, wash the separated solid with water, and dry it in an oven at 80°C to obtain HZIF-1Mo crystalline matter.

Embodiment 3

[0059] Microwave reaction: Zn(CH 3 COO) 2 2H 2 O (0.174g, 0.8mmol), 2-mim (0.098g, 1.2mmol), H 2 MoO 4 (0.034g, 0.2mmol), put the raw materials in a bottle, add DMF, microwave in a microwave oven for 45 minutes, filter the obtained product, wash the separated solid with water, and dry it in an oven at 80°C to obtain HZIF-1Mo crystalline matter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com