Method for preparing refined industrial salt from industrial waste salt

A technology for industrial waste salt and industrial salt, applied in the field of resources and environment, can solve the problems of surrounding soil, groundwater sources, safety hazards, environmental pollution, etc., and achieve significant economic and environmental benefits, reliable principles, and low-cost effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

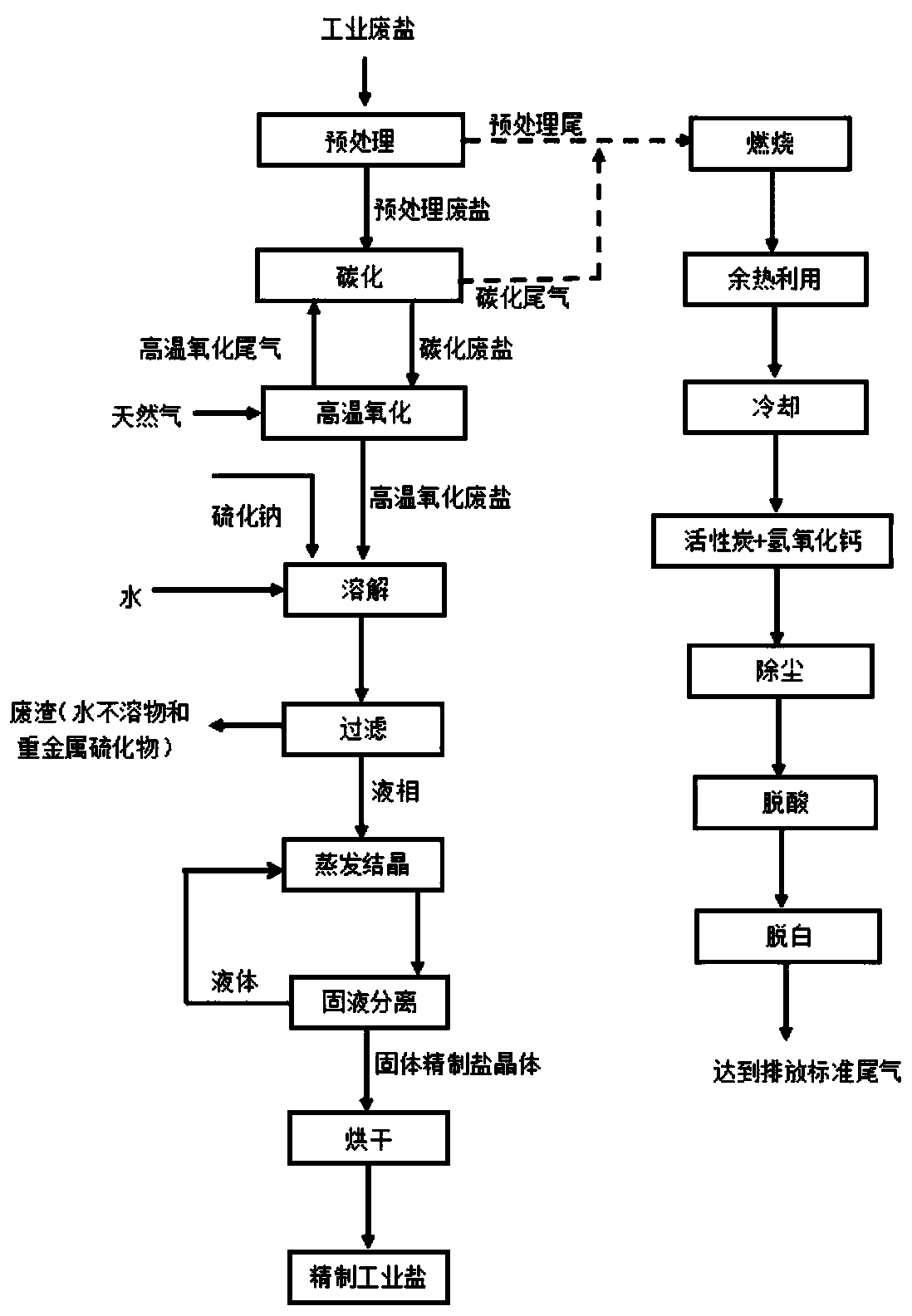

[0056] (1) Industrial waste salt pretreatment: 1000kg of industrial waste salt (containing 80wt% of sodium chloride, 14wt% of water, 5wt% of organic matter, 1wt% of water-insoluble matter, and 20ppm of total heavy metals) was crushed, sieved, and fully uniformly mixed , enter the rotary dehydration device, use natural gas to heat the hot air, heat at 150°C for 15 minutes, remove part of the water and volatile organic compounds, and obtain 855kg of pretreated waste salt; the pretreated tail gas obtained from the pretreatment is transported to the tail gas post-treatment process;

[0057] (2) Carbonization: transport the pretreated waste salt to the fluidized furnace carbonization device, use the high-temperature oxidation tail gas from the high-temperature oxidation device, heat the pretreated waste salt at 450°C, and carbonize the organic matter in the pretreated waste salt after 6 seconds. Obtain 835 kg of carbonized waste salt; the carbonized tail gas from the outlet of the f...

Embodiment 2

[0064] (1) Industrial waste salt pretreatment: 1000kg of industrial waste salt (containing 85wt% of sodium sulfate, 10wt% of water, 4.5wt% of organic matter, 0.5wt% of water-insoluble matter, and 10ppm of total heavy metals) was pulverized, sieved, and fully uniformly mixed Finally, enter the flash dehydration device, use natural gas to heat the hot air, heat at 140°C for 15 minutes, remove part of the water and volatile organic compounds, and obtain 895kg of pretreated waste salt; the pretreated tail gas obtained from the pretreatment is transported to the tail gas post-treatment process;

[0065] (2) Carbonization: transport the pretreated waste salt to the pulse carbonization device, use the high-temperature oxidation tail gas from the high-temperature oxidation device, heat the pretreated waste salt at 400°C, and carbonize the organic matter in the pretreated waste salt after 10s , to obtain 875 kg of carbonized waste salt; the carbonized tail gas from the outlet of the pul...

Embodiment 3

[0072] (1) Industrial waste salt pretreatment: 1000kg of industrial waste salt (containing 75wt% of sodium chloride, 9.5wt% of moisture, 5wt% of sodium sulfate, 10wt% of organic matter, 0.5wt% of water insoluble matter, and 30ppm of total heavy metals) was pulverized, After sieving and mixing fully and evenly, enter the rake-tooth dehydration device, use natural gas to heat the hot air, heat at 160°C for 10 minutes, remove part of the water and volatile organic compounds, and obtain 897kg of pretreated waste salt; the pretreated tail gas is transported To the tail gas post-treatment process;

[0073] (2) Carbonization: Transport the pretreated waste salt to the pulse carbonization device, use the high-temperature oxidation tail gas from the high-temperature oxidation device, heat the pretreated waste salt at 550°C, and carbonize the organic matter in the pretreated waste salt after 2s , to obtain 865 kg of carbonized waste salt; the carbonized tail gas from the outlet of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com