Tomato pomace seed and skin separating method and separating system

A technology for separating tomato skin residue and seed skin, which is applied in solid separation, chemical instruments and methods, and separation of solids from solids by air flow, etc. Use and other problems to achieve the effect of easy continuous industrial production and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

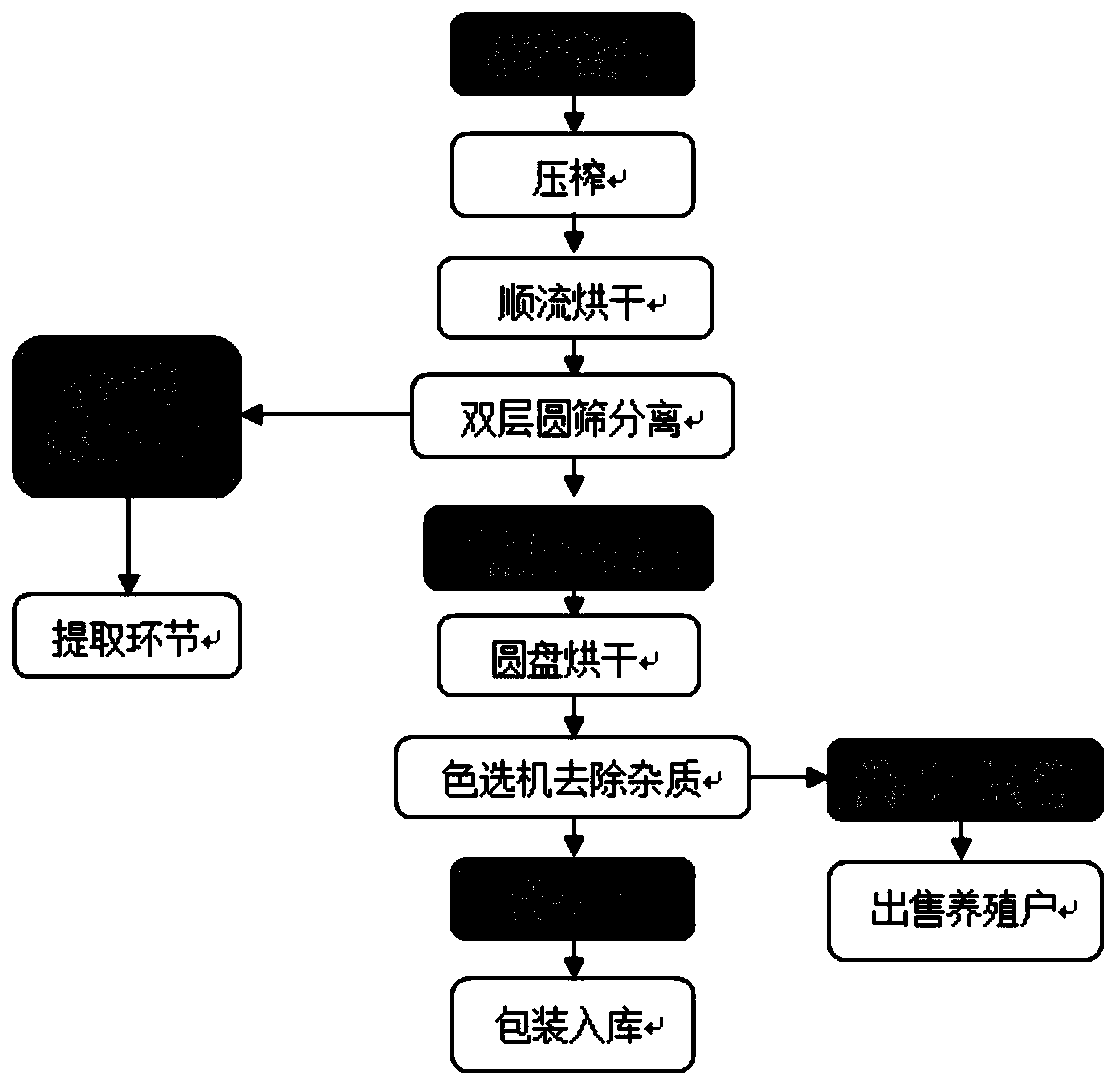

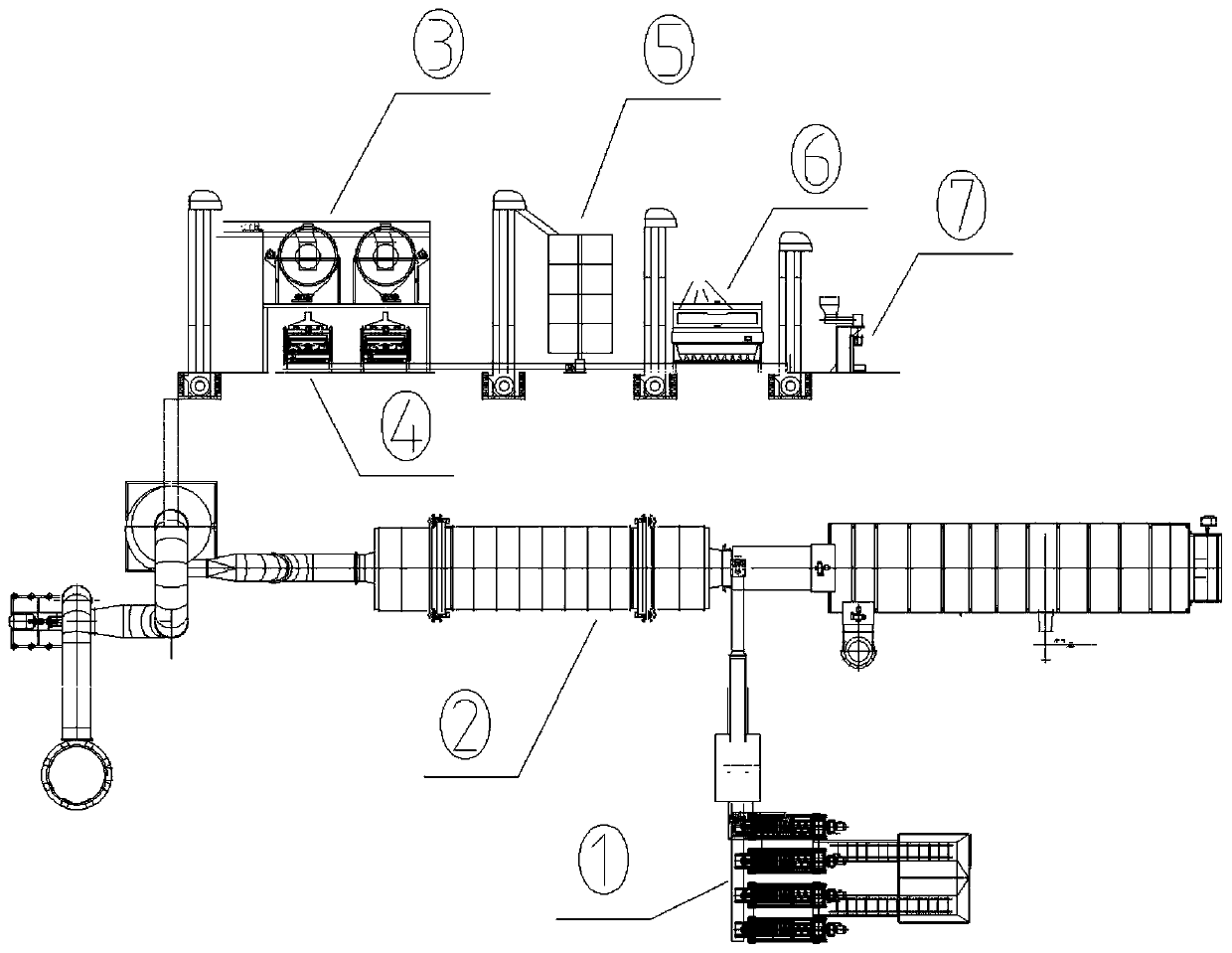

[0025] Embodiment 1: Using the by-product of the tomato paste factory as raw material, a hollow-shaft screw press is used to reduce the moisture content, so that the moisture content of the raw material is reduced from 76%-85% to 65%-73%. After pressing, the material is mixed with hot air at 280-420°C and enters the downstream hot air dryer. The outlet temperature is controlled at 90-110°C to obtain a material with a moisture content of 25-40%. 2) The material is separated into tomatoes by a double-layer round sieve Tomato seeds, tomato skin, tomato mince, tomato skin and tomato mince are used for lycopene extraction, tomato seeds enter the flat rotary sieve to remove tomato skin and tomato mince in tomato seeds, and the output tomato seeds enter the disc dryer for heating To 110-120 ℃ to reduce the moisture to 6%-9%, after drying, the tomato seeds enter the color sorter to remove heterochromatic impurities and moldy seeds to obtain pure tomato seeds with uniform color, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com