Processing method of fireproof aluminum-plastic plate

A processing method and technology for aluminum-plastic panels, which are applied in the field of fire-resistant aluminum-plastic panels, can solve the problems that the condensation pipe affects the condensation effect, the purity of the blank is insufficient, and the extrusion screw is stuck, and achieves the small particle size of the foam and the fireproof performance. High, high flexural strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

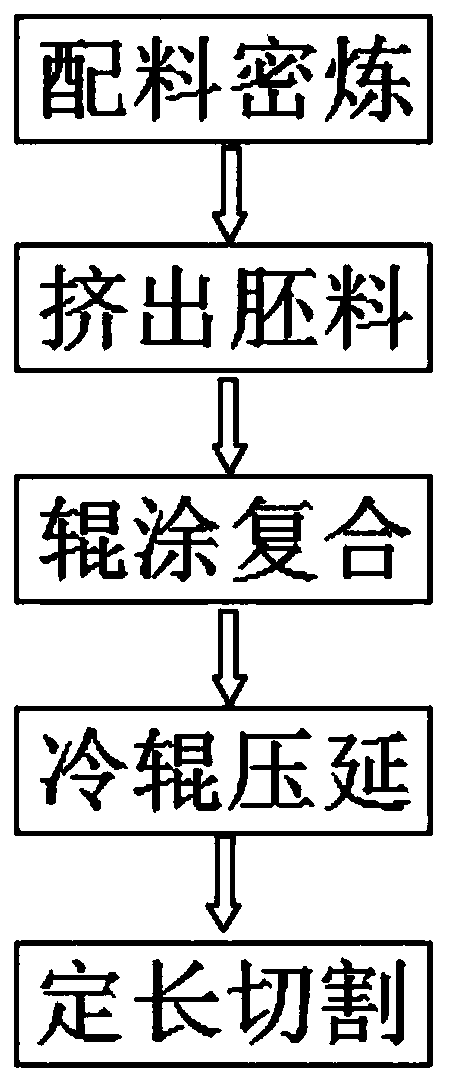

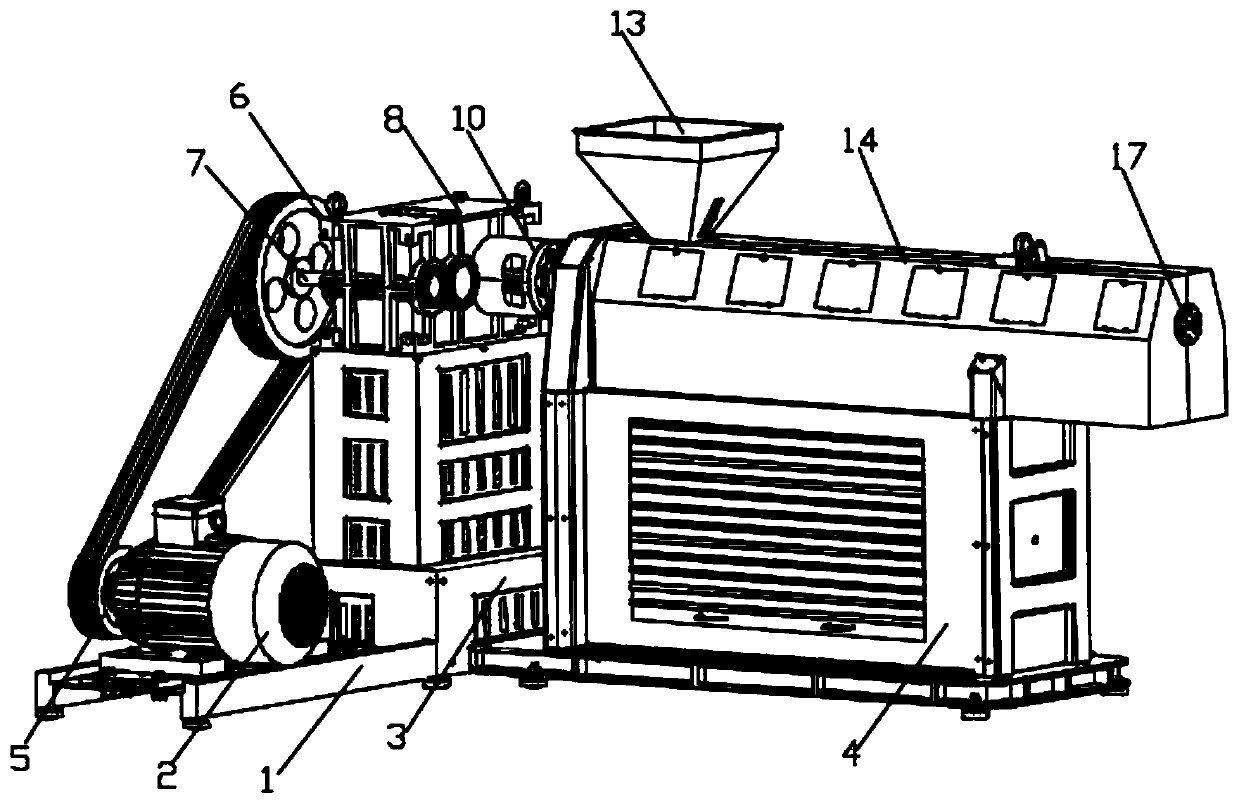

[0034] see Figure 1-5 Shown, the present invention is a kind of processing method of fireproof aluminum-plastic panel, and this processing method comprises the following steps:

[0035] Mixing ingredients: in parts by weight, weigh 51 parts of low-density polyethylene, 5 parts of aluminum hydroxide with an average particle diameter of 50 nanometers, 40 parts of magnesium hydroxide, 1.2 parts of surface treatment agent, 2 parts of interface modifier The anti-oxidant of additive, the lubricant of 0.6 part, 0.2 part is added in internal mixer and kneaded, obtains the mixture that mixes evenly after banburying;

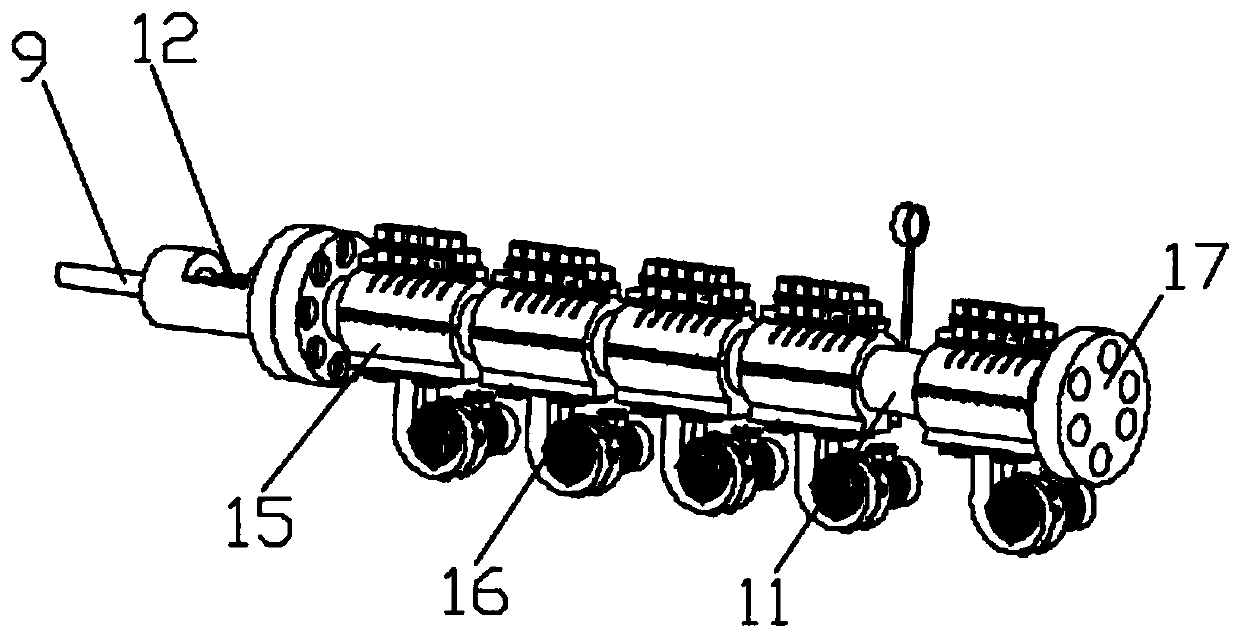

[0036] Extrude the billet: first put the kneaded mixture into the discharge pipe 13, the mixture enters the barrel 11 through the square key groove 12, the condensation pump 21 cools the inside of the condensation box 4 through the condensation pipe 22, and the cold air passes through the water absorption layer 20 enters the fixed mold shell 14, and the blower 16 discharg...

Embodiment 2

[0042] A method for processing a fireproof aluminum-plastic panel, the processing method comprising the following steps:

[0043] Mixing ingredients: in parts by weight, weigh 35 parts of high-density polyethylene, 25 parts of aluminum hydroxide with an average particle size of 1.2 microns, 30 parts of magnesium hydroxide, 5 parts of zinc borate, and 2 parts of surface Treatment agent, 2 parts of interface modifier, 0.1 part of lubricant, and 0.9 part of light stabilizer were added to the internal mixer and kneaded for 30 minutes. After banburying, a uniformly mixed mixture was obtained, and the remaining steps were the same as in Example 1;

[0044] The core material density of the fireproof aluminum-plastic panel of embodiment 2 is 0.95g / cm 3 , the tensile strength of the core material is 12.1MPa, the bending strength of the core material is 14.5MPa, the thermal conductivity of the core material is 0.04W / (M.k), and the fire performance is B1.

Embodiment 3

[0046] A method for processing a fireproof aluminum-plastic panel, the processing method comprising the following steps:

[0047] Batching internal mixing: in parts by weight, weigh 44 parts of ethylene-vinyl acetate copolymer, 1 part of aluminum hydroxide with an average particle diameter of 0.5 micron, 50 parts of magnesium hydroxide, 1 part of surface treatment agent, 3 parts of interface modifier, 0.7 parts of lubricant, and 0.3 parts of antioxidant were added to a 130°C internal mixer and kneaded for 30 minutes. After banburying, a well-mixed mixture was obtained. The rest of the steps were the same as in Example 1.

[0048] The core material density of the fireproof aluminum-plastic panel of embodiment 3 is 1.2g / cm 3 , the tensile strength of the core material is 17.7MPa, the bending strength of the core material is 16.3MPa, the thermal conductivity of the core material is 0.07W / (M.k), and the fire performance is B1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com