One-button remote ladle car positioning and automatic cap removal and capping control device

A technology for control devices and ladle cars, which is applied in safety devices, manufacturing tools, metal processing equipment, etc., can solve problems such as difficult problems, damage to steel cars, etc., to increase the rate of capping, reduce manpower, and reduce manpower The effect of resource usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the examples.

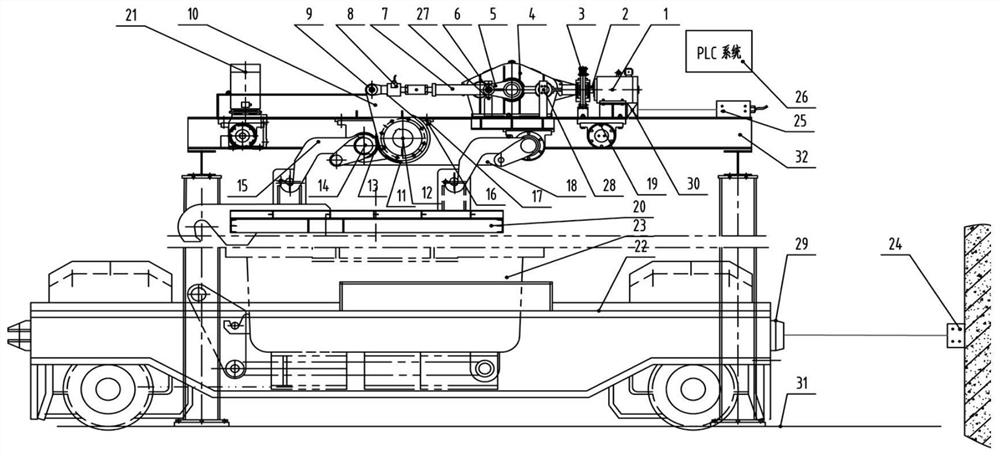

[0016] The invention discloses a one-button remote ladle car positioning and automatic cover removal control device, see figure 1 , including the ladle car 22 installed on the ladle car track 31 under the furnace, the laser receiving plate I29 installed on the end beam of the ladle car 22, and the digital laser positioning fixed on one end of the ladle car track 31 under the furnace and corresponding to the laser receiving plate I29 Device I 24, the ladle 23 set on the ladle car 22, the ladle cover 20 set on the ladle 23, the pick-and-cover trolley track 32 set above the ladle car track 31 under the furnace and corresponding to the ladle 23, set on the pick-and-cover The pick-and-cover walking trolley 19 on the trolley track 32, the digital laser locator II 25 arranged on the pick-and-cover trolley track 32 near the digital laser locator I24 end, is arranged on the pick-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com