Preparation method and application of nano-catalyst for efficiently treating trimethylamine polluted gas

A nano-catalyst and polluting gas technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as performance impact, achieve the effect of removing trimethylamine and improving degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Photoelectric coupled catalytic system removes trimethylamine

[0019] The above pretreated loads have Co-MoS 2 The conductive cathode of the catalyst is placed on one side of the membrane module, separated from the other side by a proton exchange membrane, and the anode side is placed at 0.5mol / L K 2 SO 4 Insert a copper rod into the electrolyte solution to form a corrosion metal cathode; put the assembled membrane module into the above stainless steel reactor, and use alligator clips to connect the two stages of copper wire and stainless steel mesh respectively, and the two poles are connected to the external resistance through wires to form a closed circuit. At the beginning of the experiment, trimethylamine aqueous solutions with different initial concentrations were injected from the inlet of the reactor, and a small fan fixed in the system was turned on before the reaction, so that the trimethylamine solution could be quickly volatilized and fully mix...

Embodiment 2

[0020] Example 2: Removal of trimethylamine by photoelectrocatalytic coupled microbial system

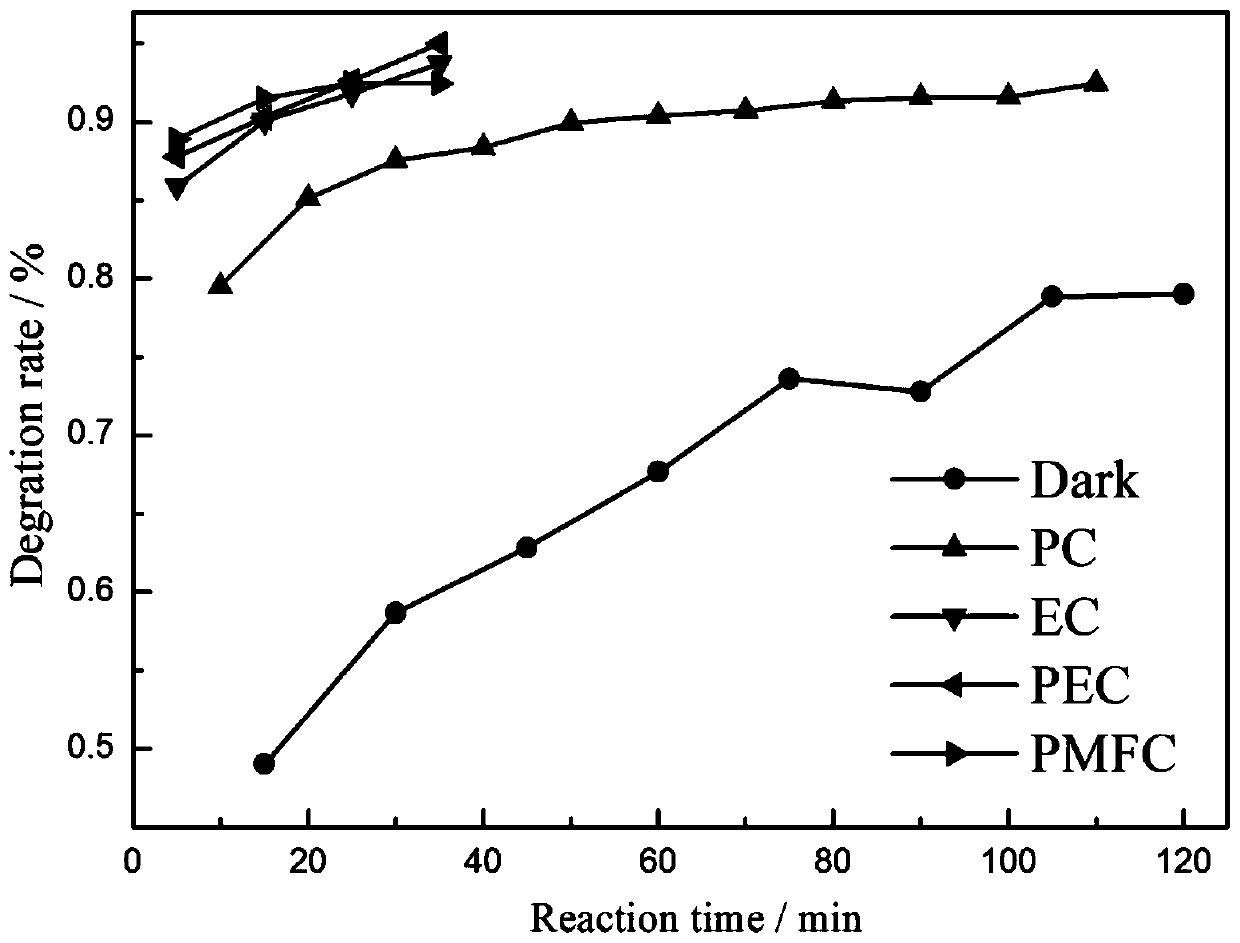

[0021] This system is essentially the same as the photoelectrocatalytic system that provides a bias voltage for metal corrosion and electricity generation. The difference is that in this system, the electricity-generating microorganism-Shewanella is used as the electricity-generating anode, and the microorganism attaches to and grows on carbon particles. On the above, the electrical energy generated by the microorganisms is exported through the inserted carbon rods, and the Co-MoS loaded 2 The conductive cathode of the catalyst forms a closed loop. Such as image 3 As shown, compared with the photocatalytic system, the efficiency of degrading trimethylamine in the photocoupled microbial system is basically the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com