Flame-retardant antistatic polyamide fiber and preparation method thereof

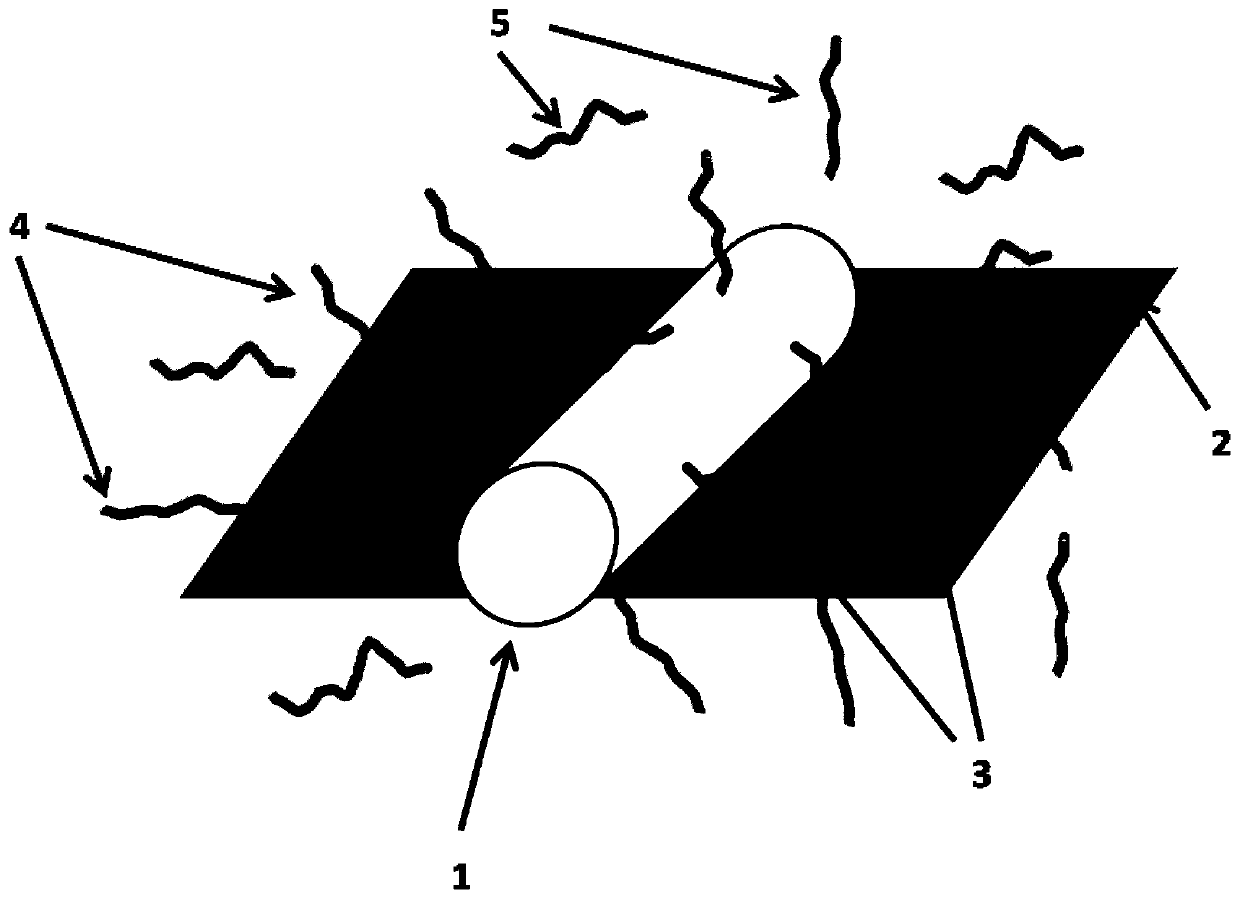

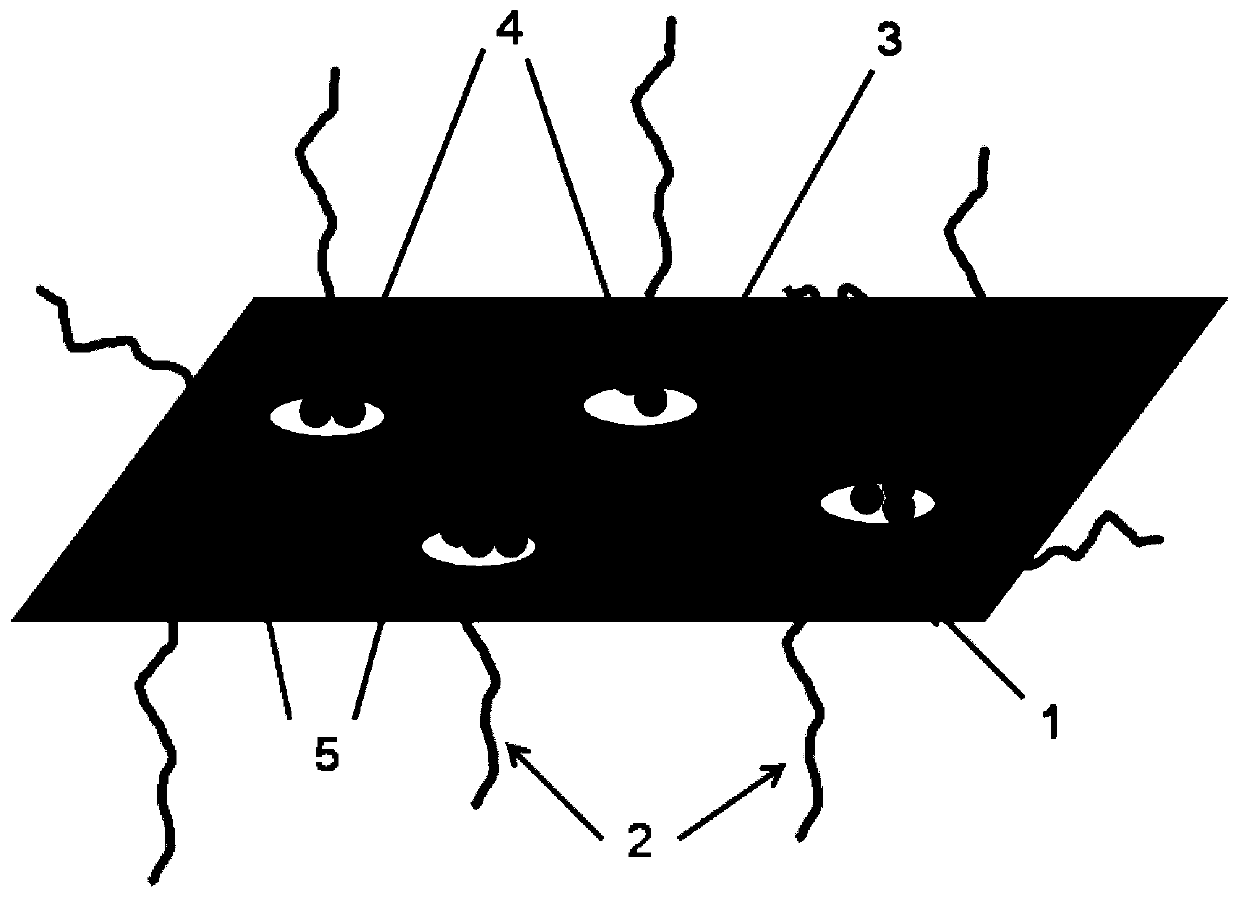

An anti-static, nylon technology, applied in the field of fibers, can solve the problems of carbon nanotubes with large specific surface area, poor dispersion effect, restricted performance, etc., and achieve the effect of improving intrinsic conductivity, developing voids, and maintaining conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

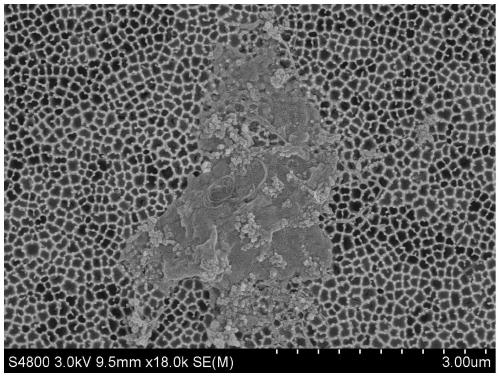

[0029](1) Add 3 parts by mass of carboxylated carbon nanotube aqueous dispersion, 4 mass parts of graphene oxide aqueous dispersion, and 0.05 mass part of molecular weight regulator into 100 mass parts of caprolactam melt, at 80°C at high speed 300 Stir to form a dispersion. The carbon-to-oxygen ratio of the carboxylated carbon nanotubes is 2.5, and the mass concentration of the carboxylated carbon nanotube aqueous dispersion is 1%. The carbon-to-oxygen ratio of the graphene oxide is 2, and the mass concentration of the graphene oxide aqueous dispersion is 1%;

[0030] (2) 0.3 parts of high DBP value nano-carbon black and 0.9 part of low DBP value nano-carbon black are mixed and added to the mixed solution obtained in step (1), and high-speed shear dispersion is carried out by an emulsifying homogenizer at 80 ° C; wherein The DBP value of nano carbon black with high DBP value is 360, and the DBP value of carbon black with low DBP value is 240;

[0031] (3) Under nitrogen pro...

Embodiment 2

[0037] (1) Add 3 parts by mass of carboxylated carbon nanotube aqueous dispersion, 4 mass parts of graphene oxide aqueous dispersion, and 0.05 mass part of molecular weight regulator into 100 mass parts of caprolactam melt, at 80 ° C at a high speed of 500 Stir to form a dispersion. The carbon-to-oxygen ratio of the carboxylated carbon nanotubes is 4, and the mass concentration of the carboxylated carbon nanotube aqueous dispersion is 2%. The carbon-to-oxygen ratio of the graphene oxide is 5, and the mass concentration of the graphene oxide aqueous dispersion is 3%;

[0038] (2) 0.3 parts of high DBP value nano-carbon black and 0.9 part of low DBP value nano-carbon black are mixed and added to the mixed solution obtained in step (1), and high-speed shear dispersion is carried out by an emulsifying homogenizer at 80 ° C; wherein The DBP value of nano carbon black with high DBP value is 400, and the DBP value of carbon black with low DBP value is 240;

[0039] (3) Under the pr...

Embodiment 3

[0045] (1) Add an aqueous dispersion of 3 mass parts of carboxylated carbon nanotubes, an aqueous dispersion of 4 mass parts of graphene oxide, and 0.3 mass parts of a molecular weight regulator into 100 mass parts of a caprolactam melt, at 80 ° C at a high speed of 500 Stir to form a dispersion. The carbon-to-oxygen ratio of the carboxylated carbon nanotubes is 6, and the mass concentration of the carboxylated carbon nanotube aqueous dispersion is 4%. The carbon-to-oxygen ratio of the graphene oxide is 4, and the mass concentration of the graphene oxide aqueous dispersion is 5%.

[0046] (2) 0.3 parts of high DBP value nano-carbon black and 1.2 parts of low DBP value nano-carbon black are mixed and added to the mixed solution obtained in step (1), and high-speed shear dispersion is carried out by an emulsifying homogenizer at 80 ° C; wherein The DBP value of nano carbon black with high DBP value is 380, and the DBP value of carbon black with low DBP value is 280;

[0047] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com