A kind of anti-corrosion coating based on cyclic carbonate active solvent and its preparation method and application

A technology of cyclic carbonate and active solvent, which is applied in the field of anti-corrosion coatings based on cyclic carbonate active solvent and its preparation, can solve the problems of difficult to achieve and reduce the solid content, achieve excellent mechanical properties, excellent performance, and ensure reliable The effect of construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

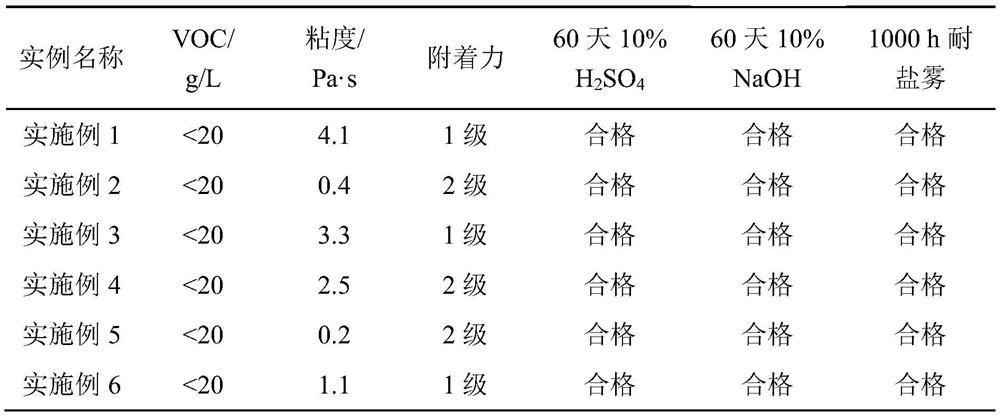

Examples

Embodiment 1

[0029] Mix 85 parts of E-51 (epoxy resin), 5 parts of glycerol triglycidyl ether, 5 parts of butylene carbonate, and 5 parts of phenyltrimethoxysilane to obtain component A; Amine, 48 parts of 650 (polyamide), and 2 parts of triphenylphosphine are mixed uniformly to obtain component B; component A and component B are uniformly mixed in a mass ratio of 100:3 to obtain an anti-corrosion coating based on a cyclic carbonate active solvent .

Embodiment 2

[0031] Mix 47 parts of E-44 (epoxy resin), 8 parts of neopentyl glycol diglycidyl ether, 15 parts of ethylene carbonate, 15 parts of diphenyldimethoxysilane, and 15 parts of tetraethyl orthosilicate Obtain component A; mix 70 parts of triethylenetetramine, 18 parts of 810 (phenalkamine), 6 parts of dimethylaniline, and 6 parts of 2,4,6-tris(dimethylaminomethyl)phenol to obtain B Components: Mix component A and component B uniformly in a mass ratio of 100:15 to obtain an anti-corrosion coating based on a cyclic carbonate active solvent.

Embodiment 3

[0033] 30 parts of E-51 (epoxy resin), 30 parts of E-20 (epoxy resin), 5 parts of 1,4-butanediol diglycidyl ether, 22 parts of trimethylolpropane triglycidyl ether, 6 Parts of glycerol carbonate and 7 parts of dimethyldimethoxysilane were mixed uniformly to obtain component A; 30 parts of diethylenetriamine, 55 parts of 651 (polyamide), 15 parts of 2,4,6-tri(dimethyl Aminomethyl) phenol is uniformly mixed to obtain component B; component A and component B are uniformly mixed according to a mass ratio of 100:25 to obtain an anti-corrosion coating based on a cyclic carbonate active solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com