Tread rubber for tire and preparation method thereof

A tire tread, butadiene rubber technology, used in special tires, tire parts, rolling resistance optimization, etc. The effect of excellent capacitance and low rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

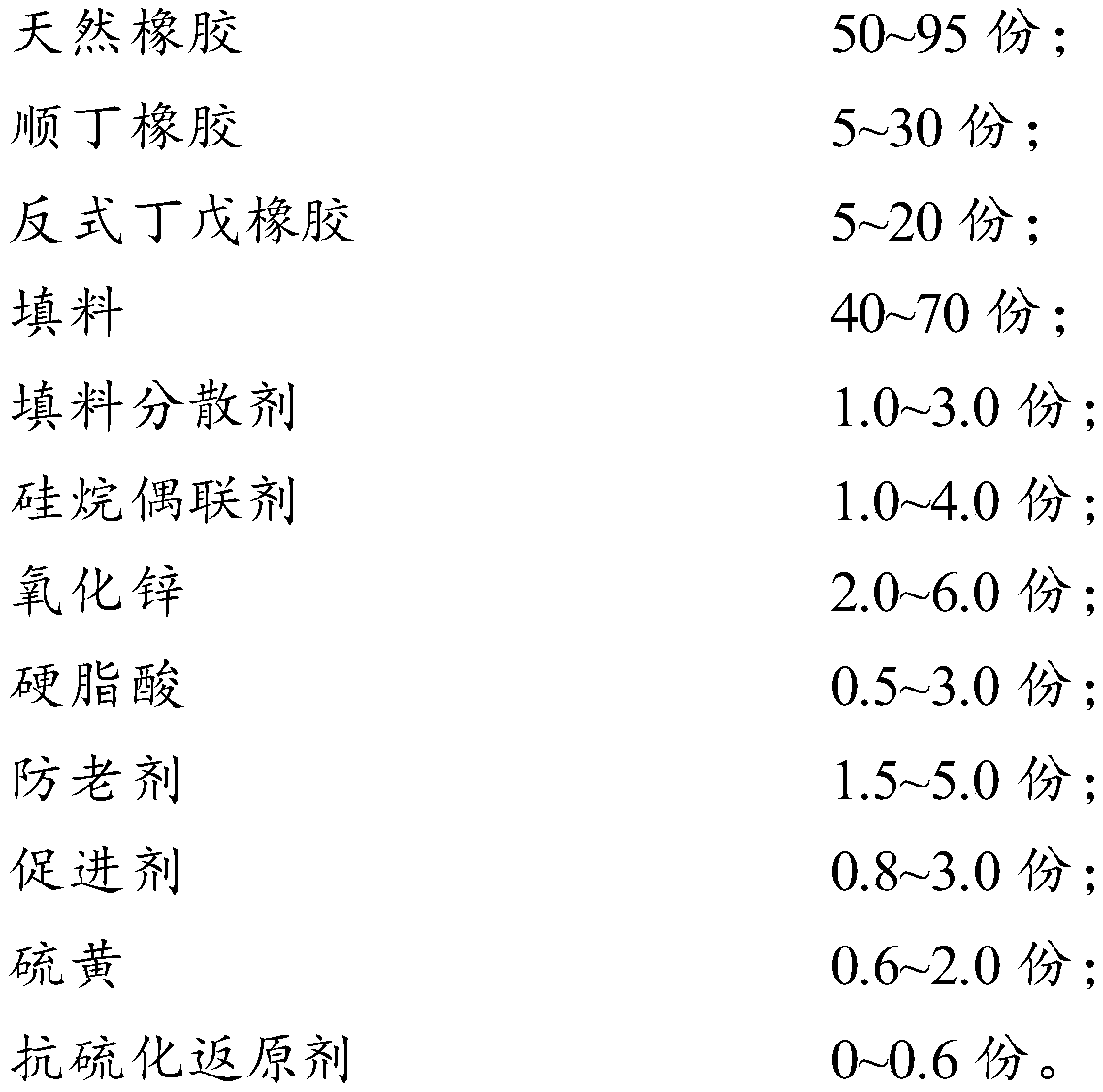

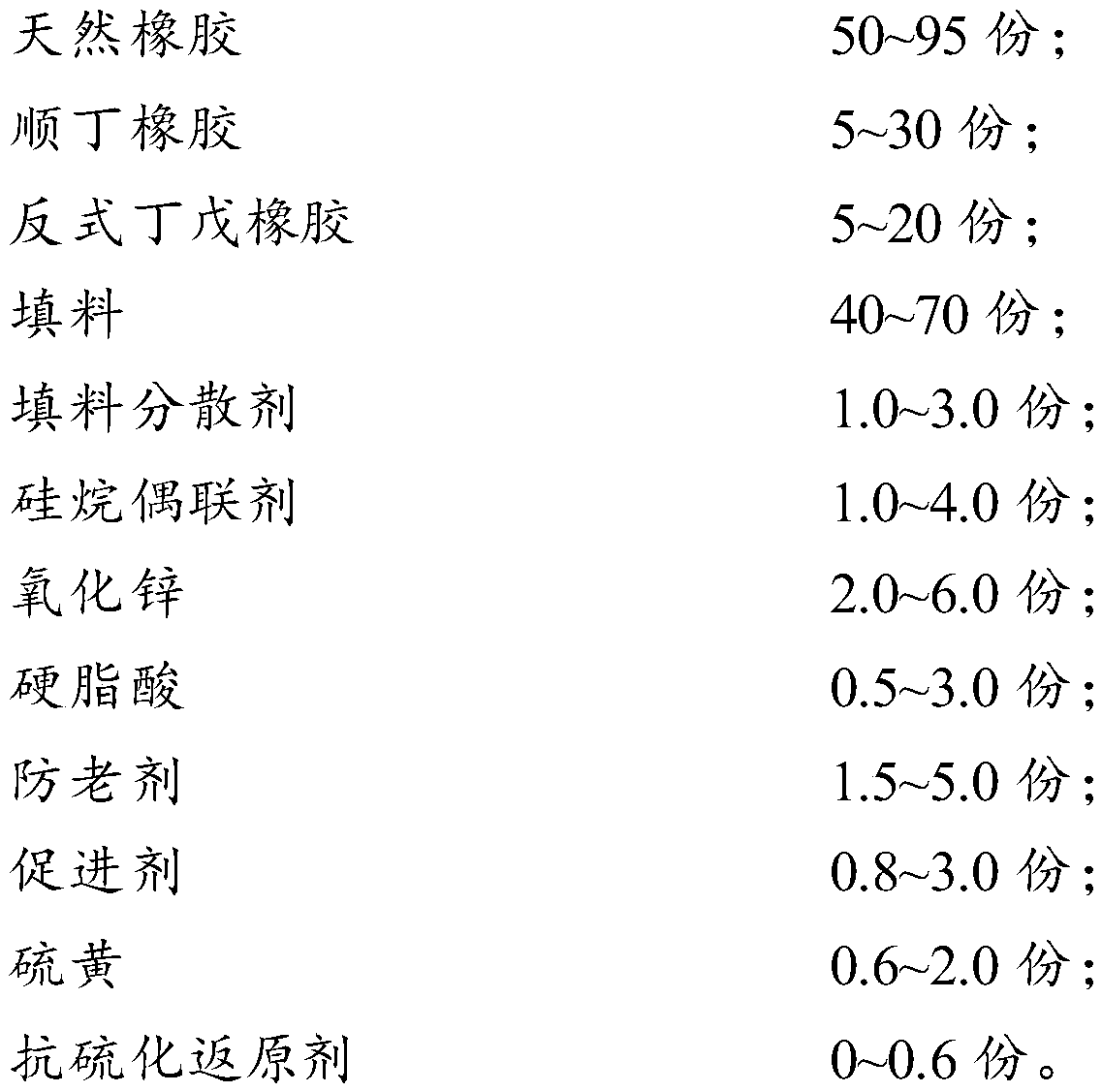

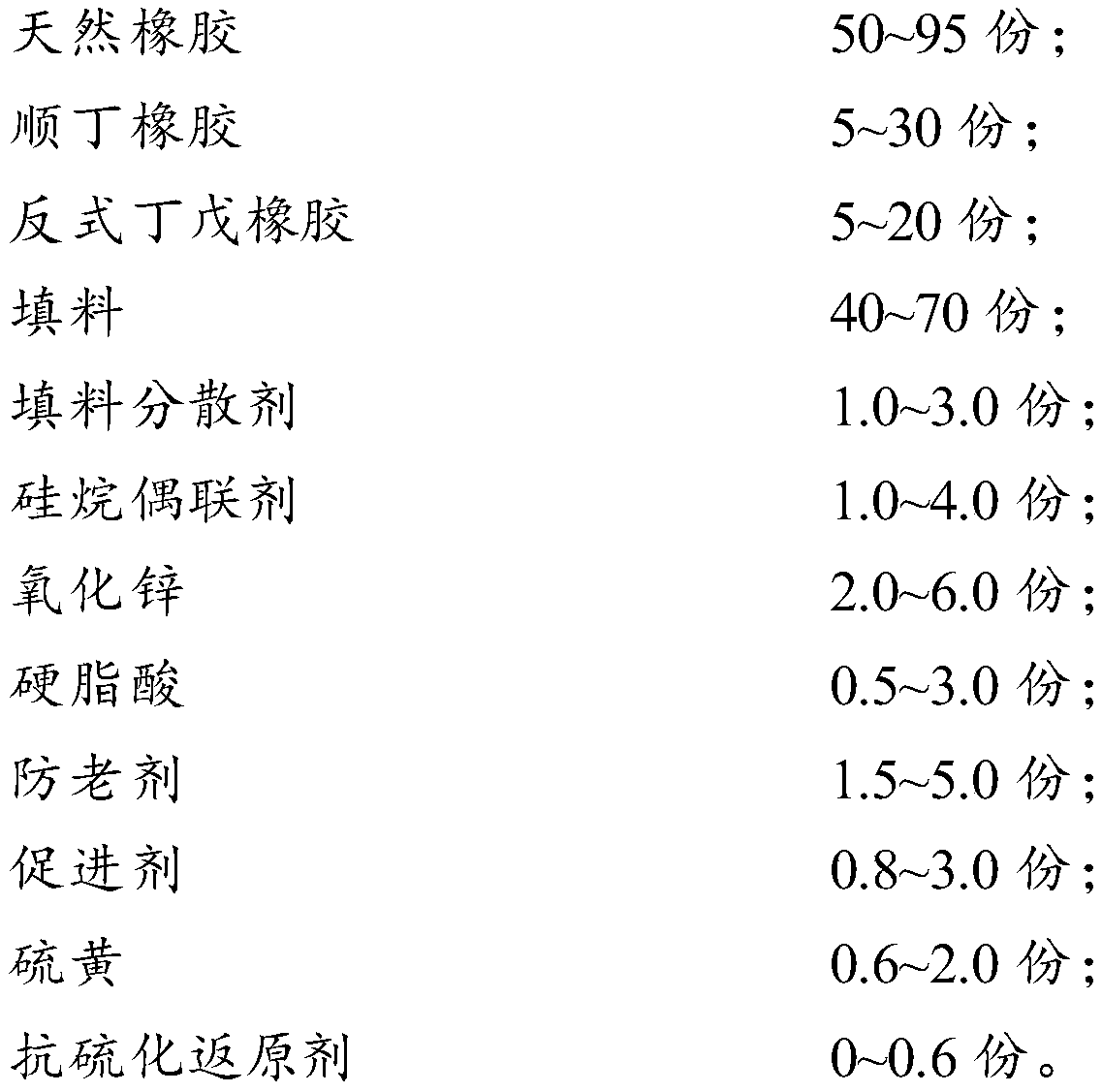

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a kind of preparation method of above-mentioned tire tread rubber, comprises the following steps:

[0046] A) banburying and mixing natural rubber, butadiene rubber, trans-butadiene rubber, zinc oxide, stearic acid, anti-aging agent, filler, filler dispersant and silane coupling agent to obtain a masterbatch;

[0047] B) banburying and mixing the first-stage masterbatch, accelerator, sulfur and anti-reversion agent to obtain a second-stage masterbatch;

[0048] C) The second-stage masterbatch is opened for kneading, and the obtained final mix is placed at a temperature of 21-25° C. and a humidity of 30-80% for 4-168 hours;

[0049] D) vulcanizing the final rubber mix after standing at a temperature of 140-180° C. and a pressure of 10-35 MPa to obtain tire tread rubber.

[0050] In the preparation method, the components and proportions of the raw materials are the same as above, and will not be repeated here. The present invention ...

Embodiment 1

[0068] First natural rubber SMR20, butadiene rubber BR 9000 and trans-butadiene rubber TBIR-0958 were banbury mixed for 1 min, then zinc oxide, stearic acid, antioxidant (1.5 parts by weight of antioxidant 4020, 1.2 parts by weight of antiaging agent agent RD and 1.0 parts by weight of paraffin), filler (carbon black N234 of 50 parts by weight and white carbon black of 20 parts), filler dispersant (carbon black dispersant) and silane coupling agent Si-69 banbury mixing 4min, The temperatures of the two banburying and blending were both 70° C., the rotation speeds were 70 rpm, and the feeding coefficients were both 0.75. The discharge temperature after the banburying and blending was 155° C. to obtain a masterbatch.

[0069] Put one section of masterbatch into internal mixer, add accelerator CBS-80, sulfur and anti-reversion agent CTP to banbury and mix to obtain second section of masterbatch; the temperature of said banbury blending is 60°C, and the speed is 40rpm, the feeding...

Embodiment 2

[0074] First natural rubber SMR20, butadiene rubber BR 9000 and trans-butadiene rubber TBIR-2058 are banbury mixed for 1min, then add zinc oxide, stearic acid, anti-aging agent (1.5 weight parts of anti-aging agent 4020, 1.2 weight parts of anti-aging agent RD and 1.0 parts by weight of paraffin), filler (carbon black N234 of 50 parts by weight and white carbon black of 20 parts), filler dispersant (carbon black dispersant) and silane coupling agent Si-69 banbury mixing 4min, The temperatures of the two banburying and blending were both 70° C., the rotation speeds were 70 rpm, and the feeding coefficients were both 0.75. The discharge temperature after the banburying and blending was 155° C. to obtain a masterbatch.

[0075] Put one section of masterbatch into internal mixer, add accelerator CBS-80, sulfur and anti-reversion agent CTP to banbury and mix to obtain second section of masterbatch; the temperature of said banbury blending is 60°C, and the speed is 40rpm, the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com