a ca 5 mg 4-x co x (vo 4 ) 6 Low-temperature sintered microwave ceramic material and its preparation method

A microwave ceramic and low-temperature sintering technology, applied in the field of functional ceramics, can solve the problem of high sintering temperature, achieve the effects of simple preparation process, stable phase formation, and simplified industrial production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

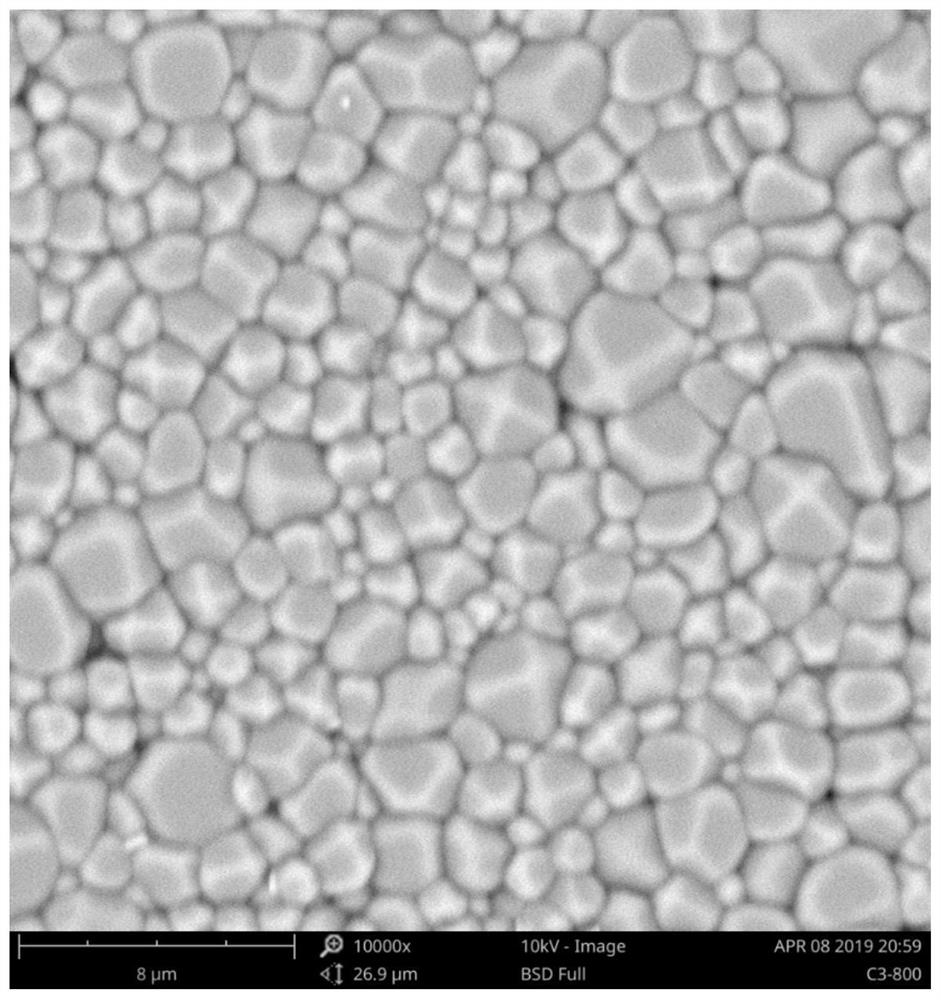

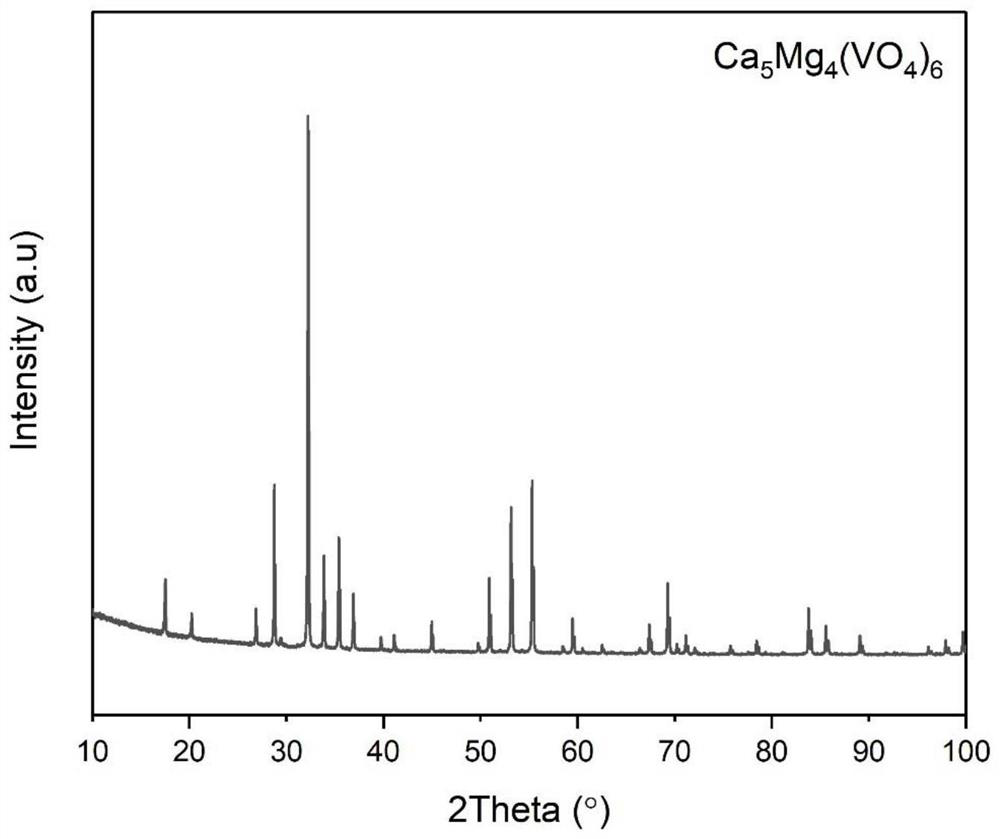

Image

Examples

Embodiment 1

[0026] According to the microwave ceramic material Ca 5 Mg 4-x co x (VO 4 ) 6 (x=0.5) stoichiometric ratio, weigh CaCO 3 , Mg(OH) 2 , CoO, V 2 o 5 A total of 30g, together with 30g of deionized water and 150g of zirconium balls, was placed in a ball milling tank for 7 hours; the slurry obtained from the ball milling was placed in an oven at a temperature of 100°C for drying, then ground and sieved; the obtained uniformly dispersed powder The body is placed in a sintering furnace and pre-sintered at 700°C for 3 hours; the obtained pre-sintered material is ball-milled again for 7 hours, then dried and granulated. The binder used is a polyvinyl alcohol solution with a mass concentration of 5%, and dried The green body was obtained after pressing; the green body was sintered at 800°C for 7 hours to prepare a low-temperature sintered microwave ceramic material, and its microwave dielectric properties were tested as follows: ε r =9.73, Q×f=47751GHz, τ f = -55.9 ppm / °C.

Embodiment 2

[0028] According to the microwave ceramic material Ca 5 Mg 4-x co x (VO 4 ) 6 (x=1) stoichiometric ratio, weigh CaCO 3 , Mg(OH) 2 , CoO, V 2 o 5 A total of 30g, together with 30g of deionized water and 150g of zirconium balls, was placed in a ball milling tank for 7 hours; the slurry obtained from the ball milling was placed in an oven at a temperature of 100°C for drying, then ground and sieved; the obtained uniformly dispersed powder The body is placed in a sintering furnace and pre-sintered at 700°C for 3 hours; the obtained pre-sintered material is ball-milled again for 7 hours, then dried and granulated. The binder used is a polyvinyl alcohol solution with a mass concentration of 5%, and dried The green body was obtained after pressing; the green body was sintered at 800°C for 7 hours to prepare a low-temperature sintered microwave ceramic material, and its microwave dielectric properties were tested as follows: ε r =9.65, Q×f=54685GHz, τ f = -55.3 ppm / °C.

Embodiment 3

[0030] According to the microwave ceramic material Ca 5 Mg 4-x co x (VO 4 ) 6 (x=1.5) stoichiometric ratio, weigh CaCO 3 , Mg(OH) 2 , CoO, V 2o 5 A total of 30g, together with 30g of deionized water and 150g of zirconium balls, was placed in a ball milling tank for 7 hours; the slurry obtained from the ball milling was placed in an oven at a temperature of 100°C for drying, then ground and sieved; the obtained uniformly dispersed powder The body is placed in a sintering furnace and pre-sintered at 700°C for 3 hours; the obtained pre-sintered material is ball-milled again for 7 hours, then dried and granulated. The binder used is a polyvinyl alcohol solution with a mass concentration of 5%, and dried The green body was obtained after compression molding; the green body was sintered at 775°C for 7 hours to prepare a low-temperature sintered microwave ceramic material, and its microwave dielectric properties were tested as follows: ε r =10.05, Q×f=47534GHz, τ f = -55.9 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| dielectric properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com