Scrub-resistant and highly-durable travertine and construction technology thereof

A scrub-resistant and durable technology, applied in the field of ecological jade mud, can solve the problems of poor durability, diatom mud walls that are not resistant to dirt and scrubbing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

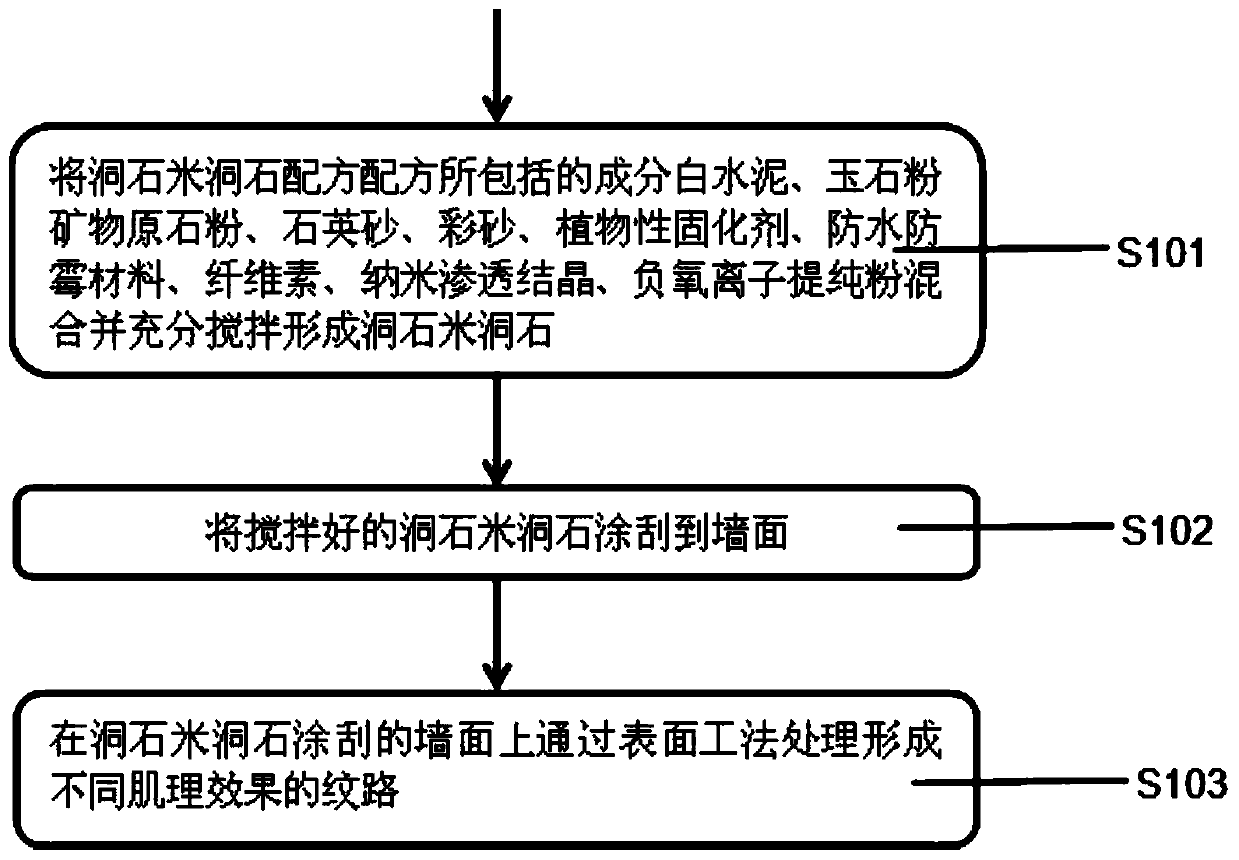

Method used

Image

Examples

Embodiment

[0035] The present embodiment: a scrub-resistant high-durability travertine rice travertine, including travertine rice travertine formula, its components include white cement, jade powder mineral raw stone powder, quartz sand, colored sand, plant-based curing agent, each The proportions of the ingredients calculated by weight percentage are: white cement: 10% to 50%, jade powder mineral raw stone powder: 10% to 80%, quartz sand: 0 to 80%, colored sand: 0 to 30%, vegetable Curing agent: 5% to 10%, the sum of the above components is 100%.

[0036] The formula of travertine and rice travertine is adopted, and its ingredients include white cement, jade powder mineral raw stone powder, quartz sand, colored sand, and plant-based curing agent. The proportion of various ingredients calculated by weight percentage is: white cement: 10%~ 50%, jade powder mineral raw stone powder: 10%-80%, quartz sand: 0-80%, colored sand: 0-30%, vegetable curing agent: 5%-10%, the sum of the above ingre...

Embodiment 2

[0068] The travertine rice travertine formula, its preferred components include white cement, jade powder mineral raw stone powder, quartz sand, colored sand, plant-based curing agent, waterproof and mildew-proof material, cellulose, nano-osmotic crystallization, negative oxygen ion purification powder , the preferred proportions of its various components calculated by weight percentage are: white cement: 20% to 50%, jade powder mineral raw stone powder: 20% to 80%, quartz sand: 10 to 20%, colored sand: 10 to 20% %, plant-based curing agent: 5% to 10%, waterproof and anti-mildew material: 0.1% to 5%, cellulose: 0.1% to 10%, nano-osmotic crystallization: 0.1% to 20%, negative oxygen ion purification powder: 0.1% %~10%, the sum of the above ingredients is 100%.

Embodiment 3

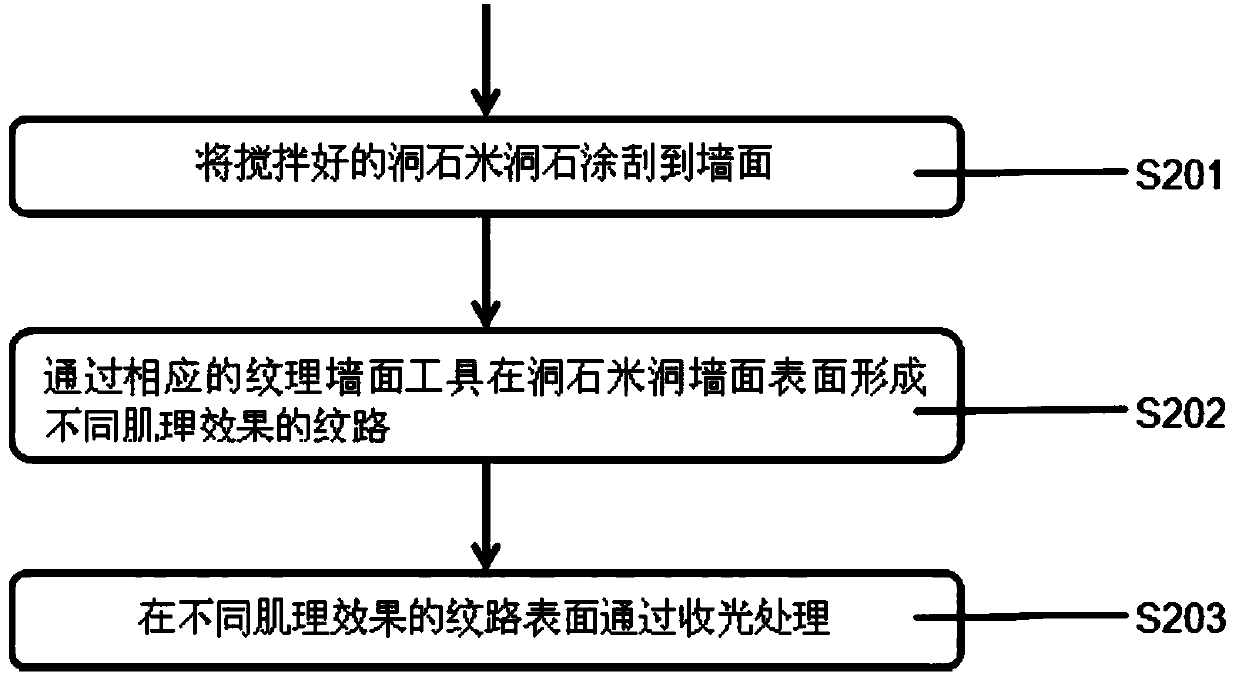

[0070] Mix the ingredients included in the travertine rice travertine formula: white cement, jade powder, mineral raw stone powder, quartz sand, colored sand, plant-based curing agent, waterproof and mildew-proof material, cellulose, nano-osmotic crystallization, and negative oxygen ion purification powder And fully stir to form the ecological jade mud hole stone rice hole stone material, the proportion of its various components calculated by weight percentage is: white cement: 20% to 50%, jade powder mineral raw stone powder: 20% to 80%, quartz sand: 10-20%, colored sand: 10-20%, vegetable curing agent: 5%-10%, waterproof and mildew-proof material: 0.1%-5%, cellulose: 0.1%-10%, nano-osmotic crystallization: 0.1% ~20%, negative oxygen ion purification powder: 0.1%~10%, the sum of the above ingredients is 100%, scrape the stirred ecological jade mud hole stone rice hole stone material onto the wall, and put it on the ecological jade mud hole stone rice Use a spatula to flatten ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com