Lightweight high-strength high-ductility mortar and preparation method thereof

A high-ductility, high-strength technology, applied in the field of building materials, can solve problems such as insufficient charge-to-mass ratio, low elastic modulus, and high density, and achieve the effects of simple preparation method, improved durability, and reduced density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0083]

[0084] The preparation method of lightweight high-strength high-ductility mortar of the present invention comprises the following steps:

[0085] (1), 300-600 parts of cement, 100-250 parts of silica fume, 0-450 parts of slag powder, 0-250 parts of recycled powder, 0-300 parts of fly ash floating beads, 0-200 parts of glass microspheres and Add 0-300 parts of regenerated rubber powder into the mixer and mix well, then dry the powder and stir to obtain the first mixture;

[0086] (2) Add the mixed liquid of 20-50 parts of water reducer and 150-300 parts of water into the first mixture and stir to make the dry powder into a slurry to obtain the second mixture;

[0087] (3), adding 5-15 parts of ultra-high molecular weight polyethylene fibers and 0-10 parts of polyester fibers into the second mixture in batches and stirring to obtain a third mixture;

[0088] (4) Finally, transfer the third mixture into the mold, vibrate and form it, and perform standard curing after ...

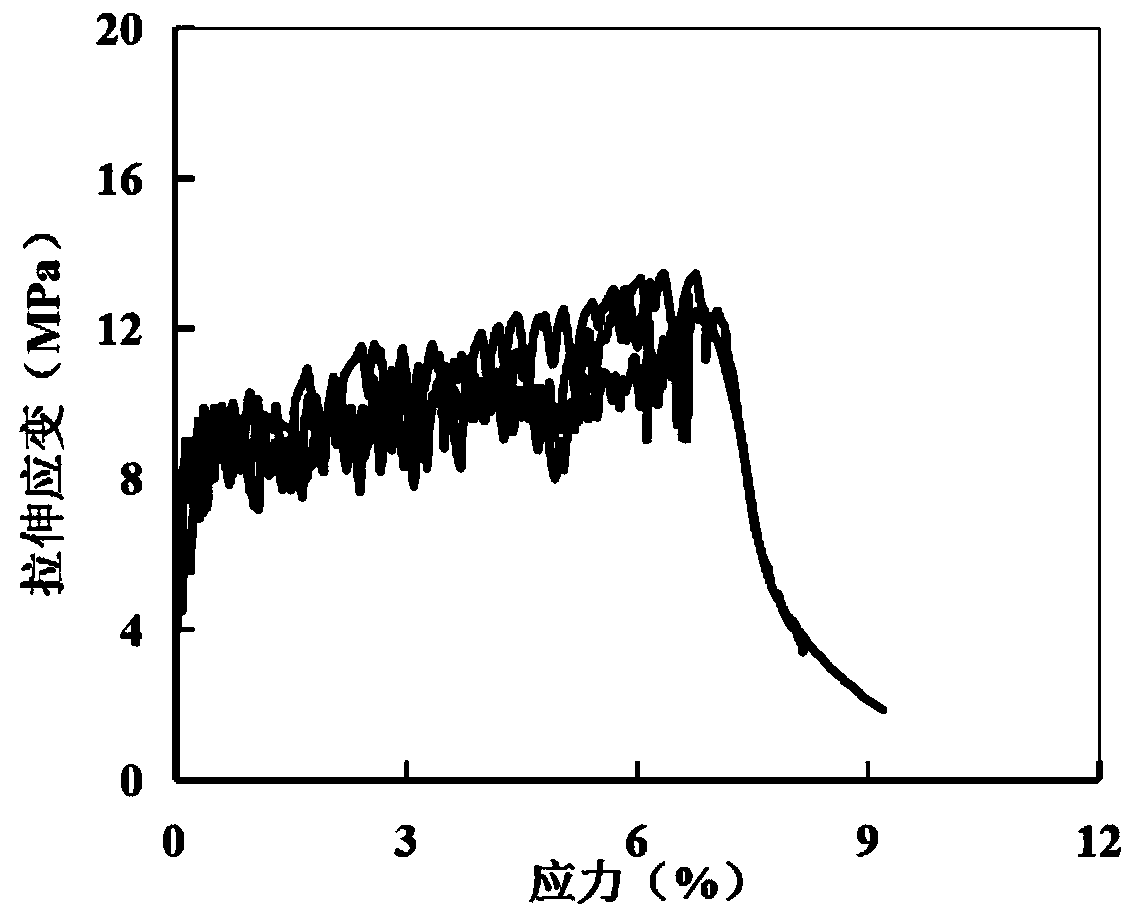

Embodiment 1

[0099] Contain three products in the present embodiment, and its serial number is recorded as 1-1, 1-2, 1-3 respectively.

[0100] The light, high-strength and high-ductility mortar of this embodiment includes P.O.52.5 (28-day compressive strength of cement>52.5MPa) ordinary Portland cement, silica fume, slag powder, recycled powder, fly ash floating beads, water reducing agent, Tap water and UHMWPE fibers. Each component is shown in Table 1 below, and each part in the table is the content in parts by weight. The length of the ultra-high molecular weight polyethylene fiber in Table 1 is 12 mm, and the aspect ratio is 600.

[0101] Table 1 product components and parts by weight content

[0102]

[0103] The preparation method of the lightweight high-strength high-ductility mortar of the present embodiment comprises the following steps:

[0104] (1) Add cement, silica fume, slag powder, regenerated powder, and fly ash floating beads into the mixer and mix well, and stir the...

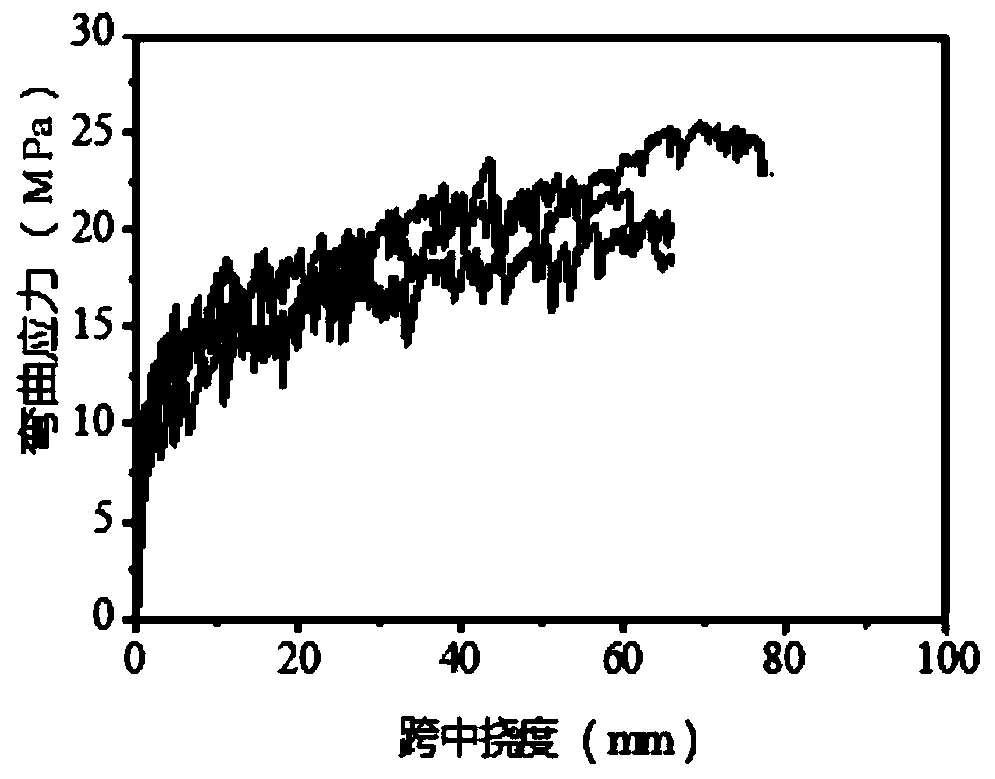

Embodiment 2

[0112] Contain three products in this embodiment, and its serial number is marked as 2-1, 2-2, 2-3 respectively.

[0113] The light, high-strength and high-ductility mortar of this embodiment includes P.O.52.5 (28-day compressive strength of cement > 52.5MPa) ordinary Portland cement, silica fume, slag powder, recycled powder, glass microspheres, water reducing agent, tap water and Ultra-high molecular weight polyethylene fibers. Each component is shown in Table 3 below, and each part in the table is the content in parts by weight. The length of the ultra-high molecular weight polyethylene fiber in Table 3 is 12 mm, and the aspect ratio is 600.

[0114] Table 3 product components and parts by weight

[0115]

[0116] The preparation method of the lightweight high-strength high-ductility mortar of the present embodiment comprises the following steps:

[0117] (1) Add cement, silica fume, slag powder, regenerated powder, and glass microspheres into the mixer and mix well, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com