Ultrasonic plastic welder for automobile fitting processing

An auto parts, ultrasonic technology, applied in the field of ultrasonic plastic welding machine, can solve the problems of slow cooling speed, poor welding effect, poor stability of welded parts, etc., to achieve the effect of improving stability and welding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

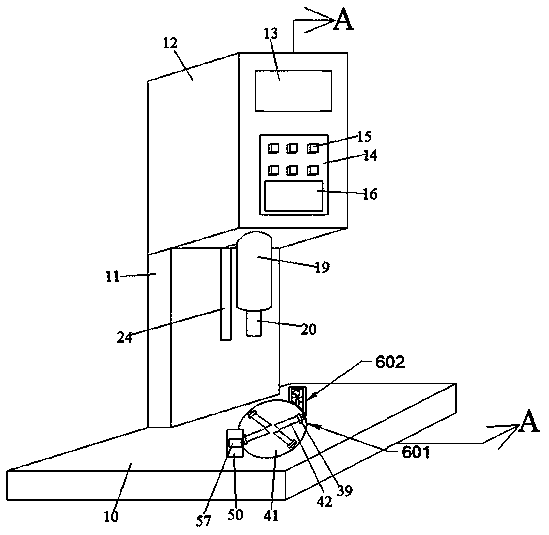

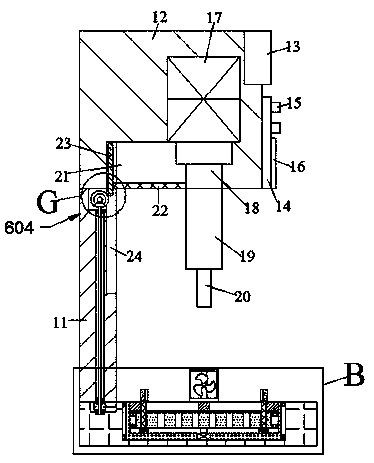

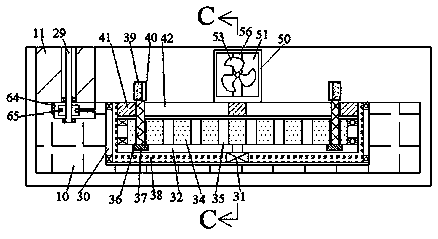

[0019] Combine below Figure 1-8 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: the up and down directions mentioned below are related to figure 1 The up and down directions of the projection relationship are the same.

[0020] refer to Figure 1-8 According to an embodiment of the present invention, an ultrasonic plastic welding machine for auto parts processing includes a base 10, and a clamping device 601 is provided inside the base 10, and the clamping device 601 can clamp the auto parts to be plastic-welded Tight, the outer side of the clamping device 601 is provided with a cooling device 602, after the plastic welding of accessories is completed, the integrity of the shape of the weldment can be maintained through the operation of the cooling device 602, and the left side of the clamping device 601 is provided with a one-way rotation device 603, the one-way rotation devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com