Machining method of second last stage and last stage moving blades of steam turbine

A processing method, a second-end technology, applied in the processing field of steam turbine blades, can solve the problems of insufficient efficiency and dimensional accuracy, great influence on product quality, and poor consistency, so as to shorten the product processing cycle, The effect of reducing labor costs and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

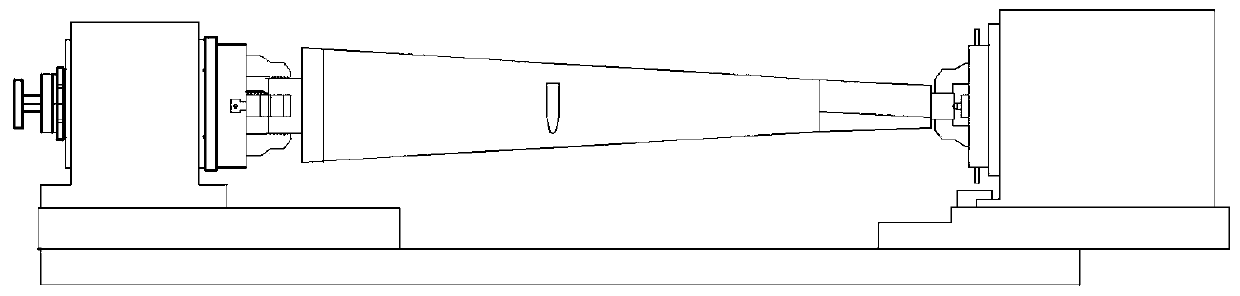

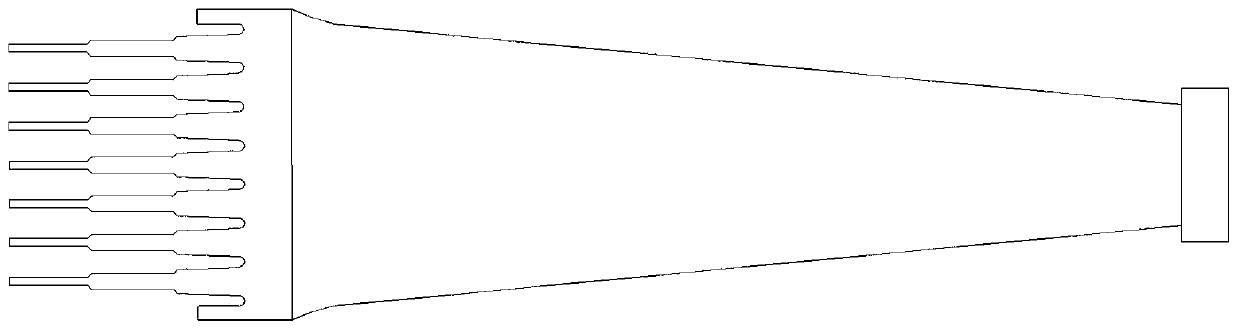

[0027] Example: as attached figure 1 and 2 As shown in the figure, a processing method for the second last stage and the last stage moving blade of a steam turbine includes finding three center positioning holes on the blade blank, positioning the blade blank through the three pinholes, and matching the blade blank on the The three center positioning holes of the blade are installed on the four-axis numerical control vertical machining center, and the invention is processed according to the fork-type blade root blade with the inner back concave-convex surface of the blade blade root.

[0028] S1: the milling two-dimensional code identification surface, two-dimensional code marking and leaf crown process head;

[0029] S2: the inner radial reference plane of the rough and fine milled blade blank; sawing and milling blade root end face; the air inlet and outlet sides of the rough and fine milling blade blank; the two positioning shoulders of the rough and fine milling blade bla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com