Method for increasing concentration of gas easy to adsorb by using pressure swing adsorption method

A pressure swing adsorption method, an easy-to-adsorb technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of unfavorable methane concentration, reduced product recovery rate, high replacement gas pressure, etc., to improve the treatment rate. , The effect of reducing the loss of recovery rate and increasing the proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

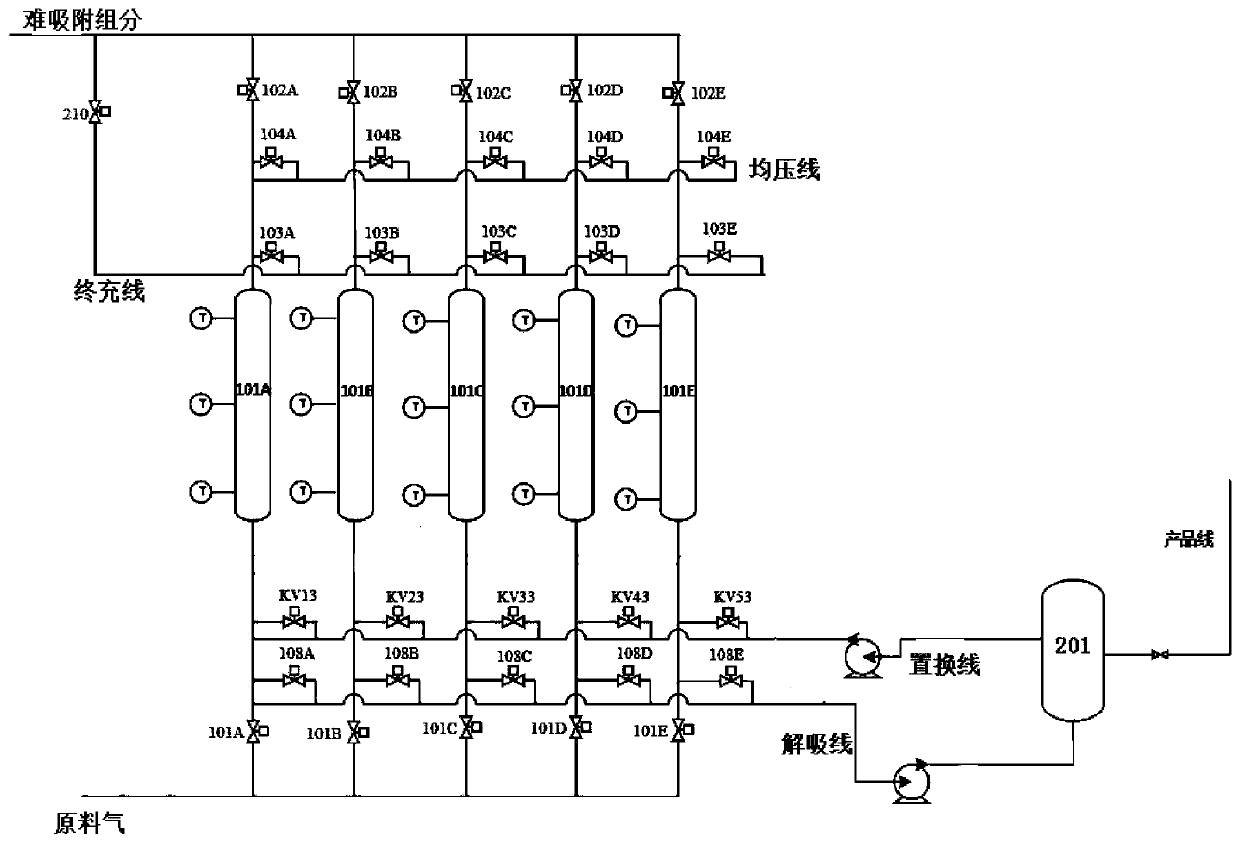

[0070] This embodiment provides a method for enriching methane by pressure swing adsorption. The method is operated by a device consisting of five adsorption towers arranged in parallel. The structural connection diagram of the device is as follows figure 1 As shown, it includes the first adsorption tower 101A, the second adsorption tower 101B, the third adsorption tower 101C, the fourth adsorption tower 101D and the fifth adsorption tower 101E, and also includes a feed line, a pressure equalization line, a replacement line, a desorption line, The final filling line, each pipeline is independently connected to 5 adsorption towers, and all of them are equipped with valves; the replacement line and the desorption line are connected to the product gas storage device 201.

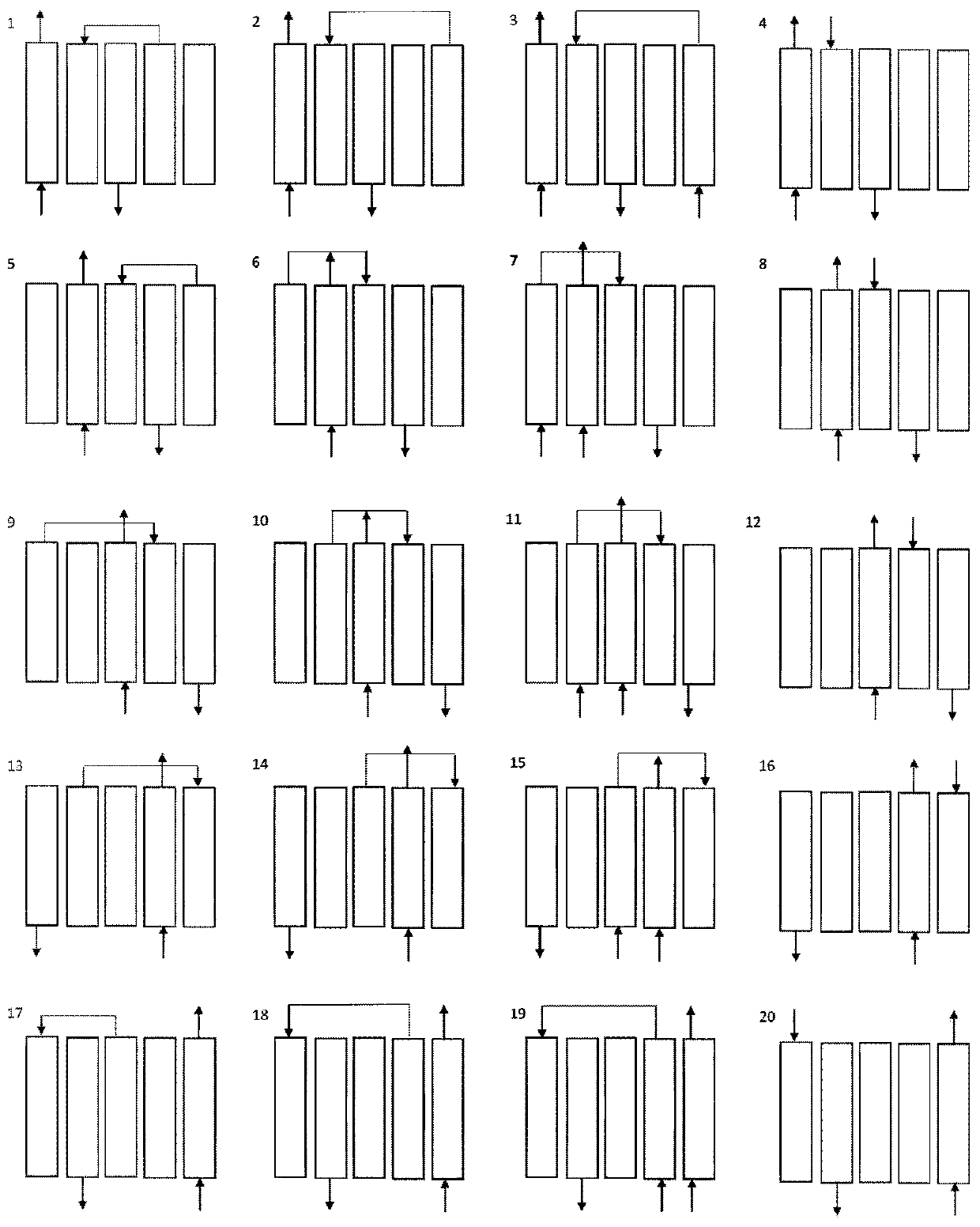

[0071] This embodiment takes the operation process of 5 towers as an example to specifically illustrate the operation process of enriching methane; wherein the adsorption pressure used is 120kPa, and the desorpt...

Embodiment 2

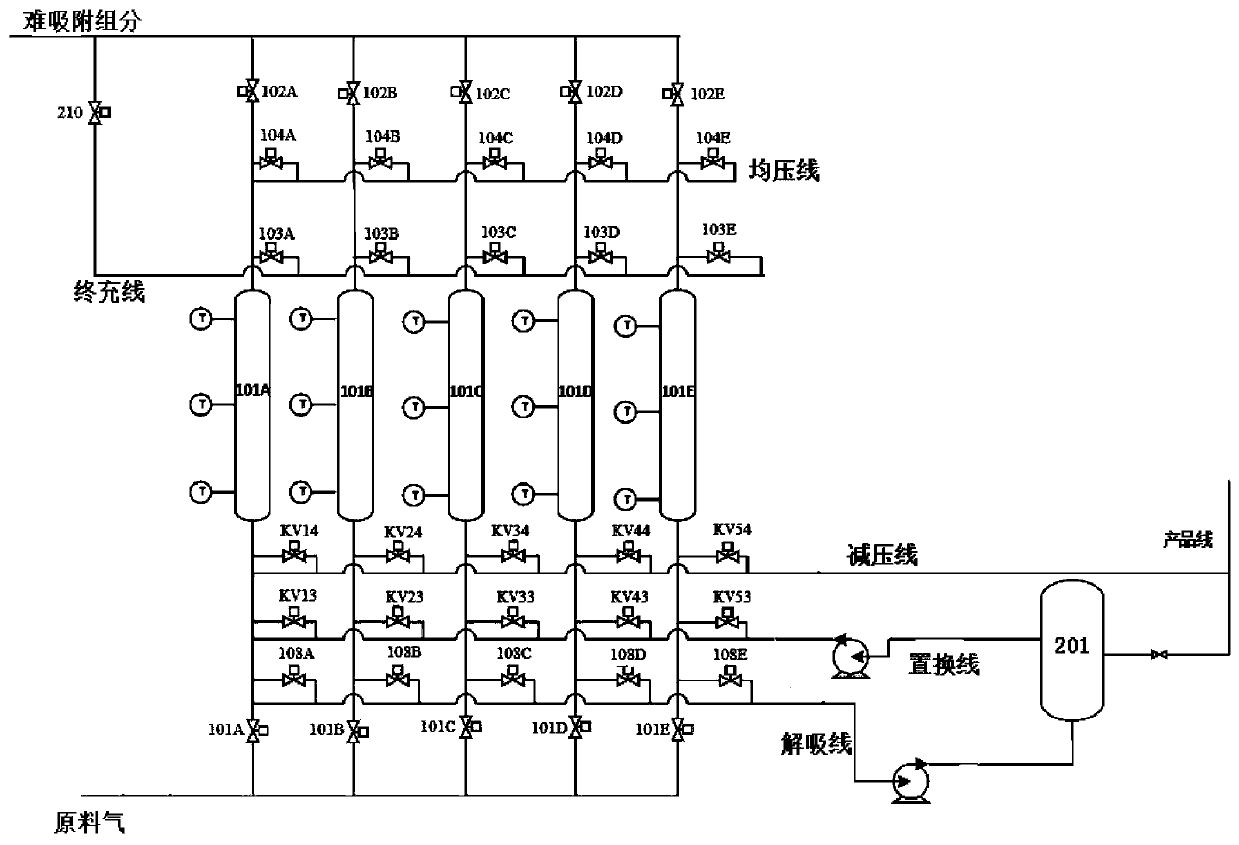

[0090] This embodiment provides a method for enriching methane by pressure swing adsorption. The method is operated by a device consisting of five adsorption towers arranged in parallel. The structural connection diagram of the device is as follows image 3 As shown, the overall structure and connection relationship are basically the same as in Example 1, the difference is that the operating pipeline includes a decompression line in addition to a feed line, a pressure equalization line, a replacement line, a desorption line, and a final filling line.

[0091] This embodiment takes the operation process of 5 towers as an example to specifically illustrate the operation process of enriching methane; wherein the adsorption pressure used is 550kPa, and the desorption pressure is 25kPa. Taking the first adsorption tower 101A as an example, it includes 18 steps of operation process, which are respectively : 1. Adsorption; 2. Adsorption; 3. Adsorption, 4. Adsorption; 5. Empty; 6. Equa...

Embodiment 3

[0110] This embodiment provides a method for enriching methane by the pressure swing adsorption method. The method is operated by a device composed of five adsorption towers arranged in parallel. The overall structure and connection relationship are basically consistent with those of Embodiment 1, the difference is that: In addition to the feed line, pressure equalization line, replacement line, desorption line, and final filling line, the operating pipeline also includes a decompression line.

[0111] In this embodiment, the operation flow of 5 towers is taken as an example, and the operation procedure for enriching methane is the same as that in Embodiment 2.

[0112] Taking the first adsorption tower 101A as an example, the 20-step operation process will be described in detail below:

[0113] 1-4. Adsorption: Open the valves 101A and 102A, the raw material gas enters the first adsorption tower 101A, and contacts with the adsorbent, the adsorption pressure is 950kPa, in whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com