Preparation method for anti-retrogradation sweet green rice balls

A production method and technology of Qingtuan, applied in the direction of food science, etc., can solve the problems of affecting the taste of Qingtuan, high degree of aging retrogradation, etc., and achieve the effect of improving anti-retrogradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

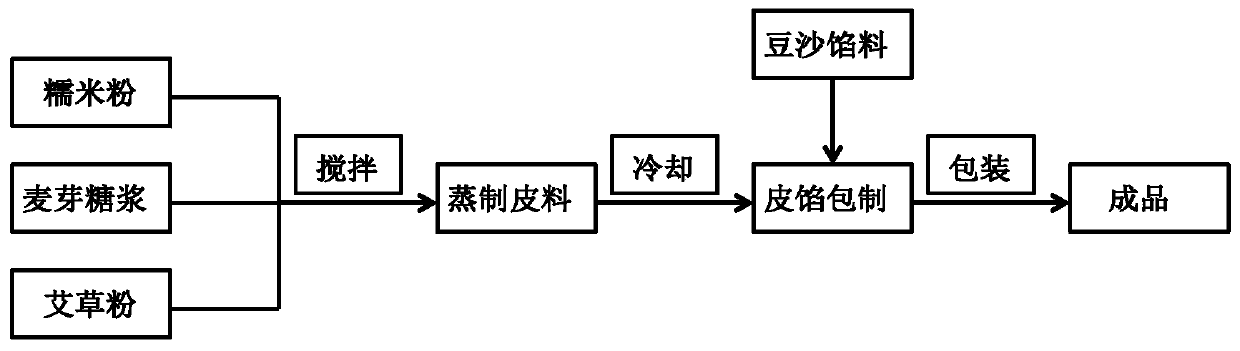

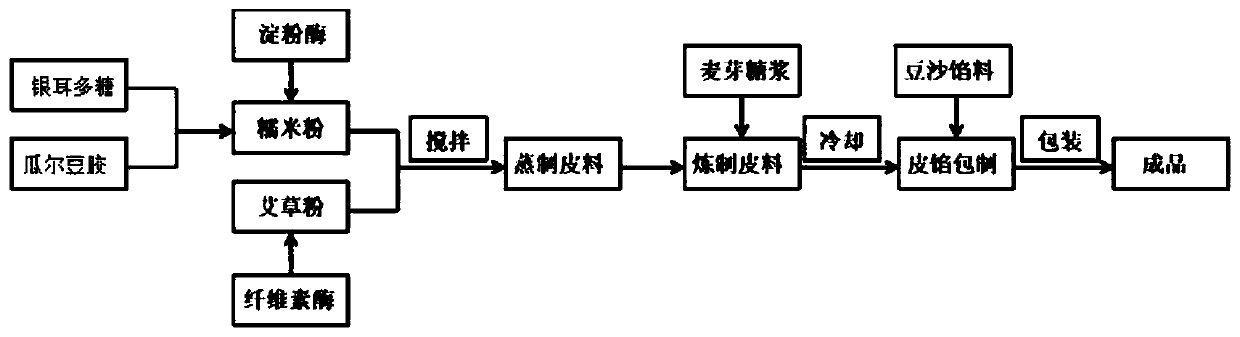

Method used

Image

Examples

Embodiment 1

[0038] (1) Wash the glutinous rice with deionized water to remove the gravel, iron filings and floating dust on the surface that may be mixed in the glutinous rice;

[0039] (2) Grind deionized water and glutinous rice into a slurry at a mass ratio of 3:1, then use a high-speed shear emulsifier for shearing treatment, use sodium bicarbonate to adjust the pH value to 6.5, and put it into a three-legged centrifuge , dehydrated at 3000r / min until no water dripped out, dried at a drying temperature of 50°C, and pulverized to 100 mesh to obtain glutinous rice flour;

[0040] (3) Tremella polysaccharide (purchased from Xi'an Fenghe Biotechnology Co., Ltd.) and guar gum (purchased from Beijing Guarrun Technology Co., Ltd.) were mixed according to the mass ratio of 2.8:1, and the mixing speed was 120r / min. Machine stirring for 250s;

[0041] (4) Fresh wormwood washes away the sediment, removes the old roots and stems, leaving only the young leaves, and fills the cooking pot with salt...

Embodiment 2

[0053] (1) Clean the glutinous rice to remove the gravel, iron filings and floating dust on the surface that may be mixed in the glutinous rice;

[0054] (2) After grinding the soaking liquid and glutinous rice into a slurry, use a high-speed shear emulsifier for shearing treatment, use sodium bicarbonate to adjust the pH value to 7.0, put it into a three-legged centrifuge, and rotate at 3200r / min Dehydrate under high temperature until no water drips out, dry at a drying temperature of 52°C, and pulverize to 100 mesh to obtain glutinous rice flour;

[0055] (3) Tremella polysaccharide and guar gum are mixed according to a mass ratio of 3.0:1, and put into a mixer with a rotating speed of 125r / min to stir for 280s;

[0056] (4) Fresh wormwood washes away the sediment, removes the old roots and stems, leaving only the young leaves, and fills the cooking pot with salt water (the mass ratio of water and salt is 1000:15), boil on high heat, and put Add the washed wormwood and blan...

Embodiment 3

[0066] (1) Clean the glutinous rice to remove the gravel, iron filings and floating dust on the surface that may be mixed in the glutinous rice;

[0067] (2) After grinding the soaking liquid and glutinous rice into a slurry, use a high-speed shear emulsifier for shearing treatment, use sodium bicarbonate to adjust the pH value to 7.5, put it into a three-legged centrifuge, and rotate at 3500r / min Dehydrate under high temperature until no water drips out, dry at a drying temperature of 55°C, and pulverize to 120 mesh to obtain glutinous rice flour;

[0068] (3) Mix tremella polysaccharide and guar gum according to the mass ratio of 3.2:1, put into a mixer with a rotating speed of 125r / min and stir for 280s;

[0069] (4) Fresh wormwood washes away the sediment, removes the old roots and stems, leaving only the young leaves, and fills the cooking pot with salt water (the mass ratio of water and salt is 1000:20), boil on high heat, put Add the washed wormwood and blanch for 1 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com