Probiotic solid beverage and preparation process thereof

A solid beverage and probiotic technology, applied to bacteria, lactobacillus, bifidobacteria and other directions used in food preparation, can solve the problems of poor overall application effect and loss, and achieve the purpose of reducing lactose intolerance, maintaining activity, The effect of regulating immune function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

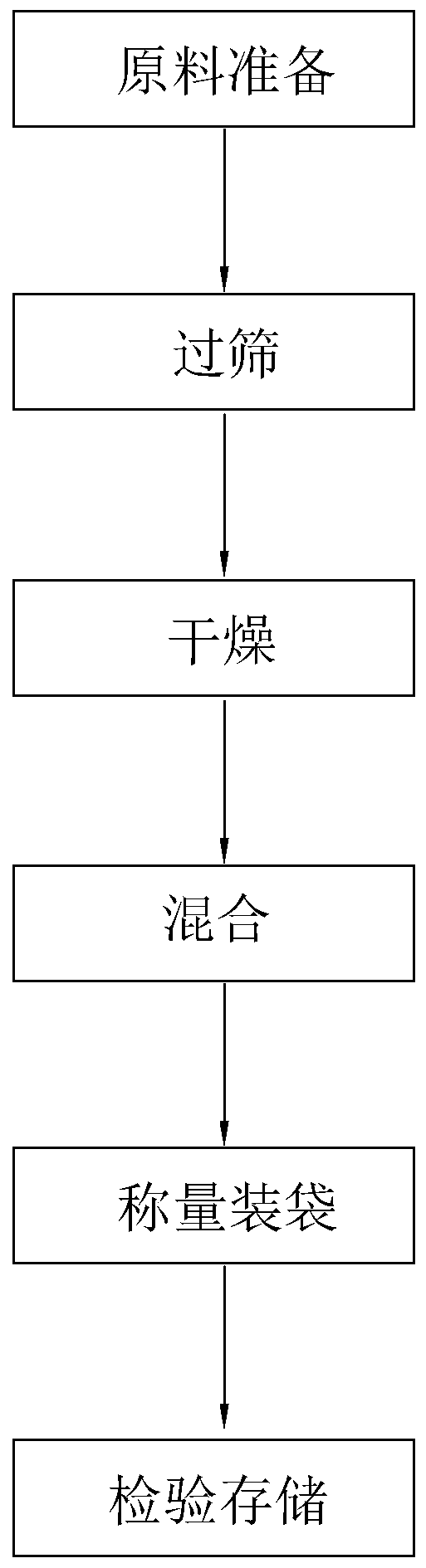

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: A kind of probiotic solid beverage, each component and its corresponding parts by weight are shown in Table 1, and it is prepared through the following steps:

[0050] Step 1, raw material preparation, anhydrous glucose, casein phosphopeptide, Lactobacillus rhamnosus HN001, Bifidobacterium animalis Bb-12, Lactobacillus acidophilus, Bifidobacterium lactis, milk reuteri Bacillus, galacto-oligosaccharides, fructo-oligosaccharides and resistant dextrin are removed from the outsourcing, and each component material with complete inner packaging is irradiated with ultraviolet light for about 15 minutes, and transferred to the ingredient room for standby;

[0051] Step 2, sieving, anhydrous glucose, casein phosphopeptide, Lactobacillus rhamnosus HN001, Bifidobacterium animalis Bb-12, Lactobacillus acidophilus, Bifidobacterium lactis, Lactobacillus reuteri, oligomeric half Lactose, fructooligosaccharides and resistant dextrin are removed from the inner bag, passed ...

Embodiment 2-8

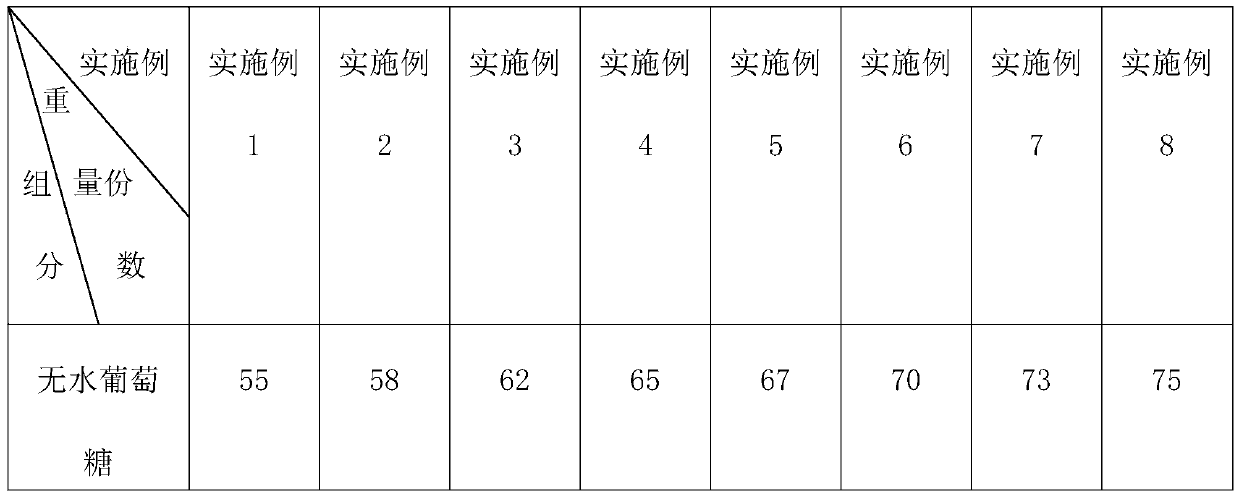

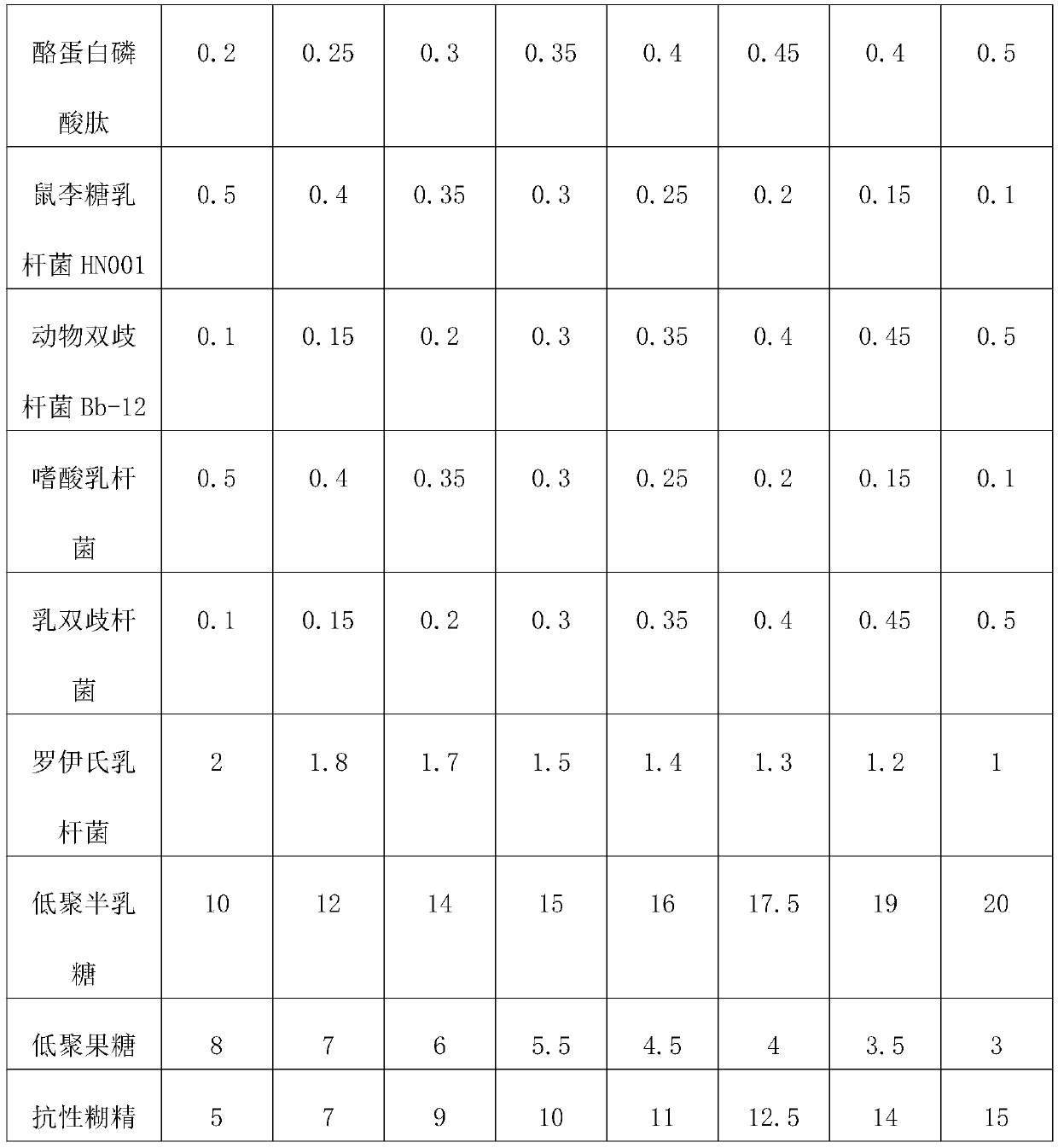

[0056] Embodiment 2-8: A probiotic solid beverage, the difference from Embodiment 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0057] Each component and parts by weight thereof in table 1 embodiment 1-8

[0058]

[0059]

Embodiment 9

[0060] Embodiment 9: A probiotic solid beverage, the difference from Example 1 is that in step 4, 5 parts by weight of resistant dextrin and 10 parts of oligomeric semi Lactose, 8 parts of fructo-oligosaccharides, the remaining amount of anhydrous glucose and 2.5 parts of drying protection agent, and the drying protection agent is selected from gelatin, mixed evenly to obtain the total mixed powder, the total mixing time is 20 minutes and then passed through a 40-mesh sieve , after the mixing is completed, the probiotic solid drink is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com