A research and development method for weathering steel based on rapid collection of corrosion data

A weather-resistant steel, fast technology, applied in the direction of weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., can solve the problems of large error in test results, short test time, errors, etc., to achieve true and reliable test results and short test time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

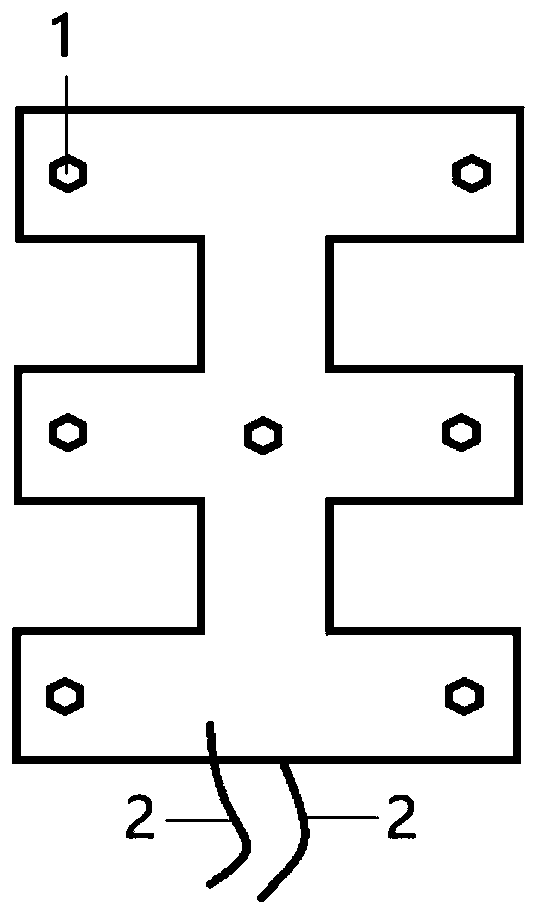

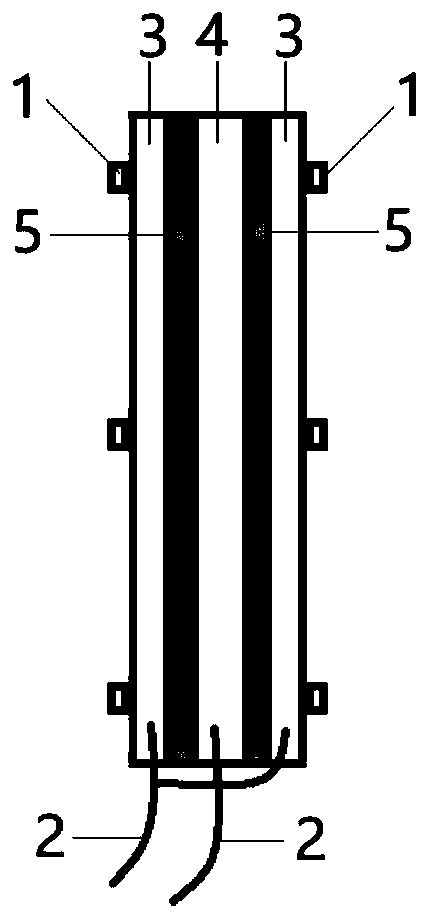

[0033] Select 3 different varieties of weather-resistant steel plates, brass plates and PVC plates, and use wire cutting to make test pieces with a length of 60mm, a width of 25mm, and a thickness of 0.5mm; -Stack the weathering steel test piece-insulation piece-copper test piece" in the order of arrangement; drill 7 3mm threaded holes in the stacked test piece group and fix the test piece group with M3 insulating nylon bolts, according to figure 1 and figure 2 The electrode is produced by cutting and processing in the same way, the weather-resistant steel test piece in the electrode is connected to the negative electrode of the commercially available microcurrent meter with a low-resistivity wire, and the two copper test pieces in the electrode are connected in parallel with a low-resistivity wire and connected to Positive electrode of a commercially available microgalvanometer.

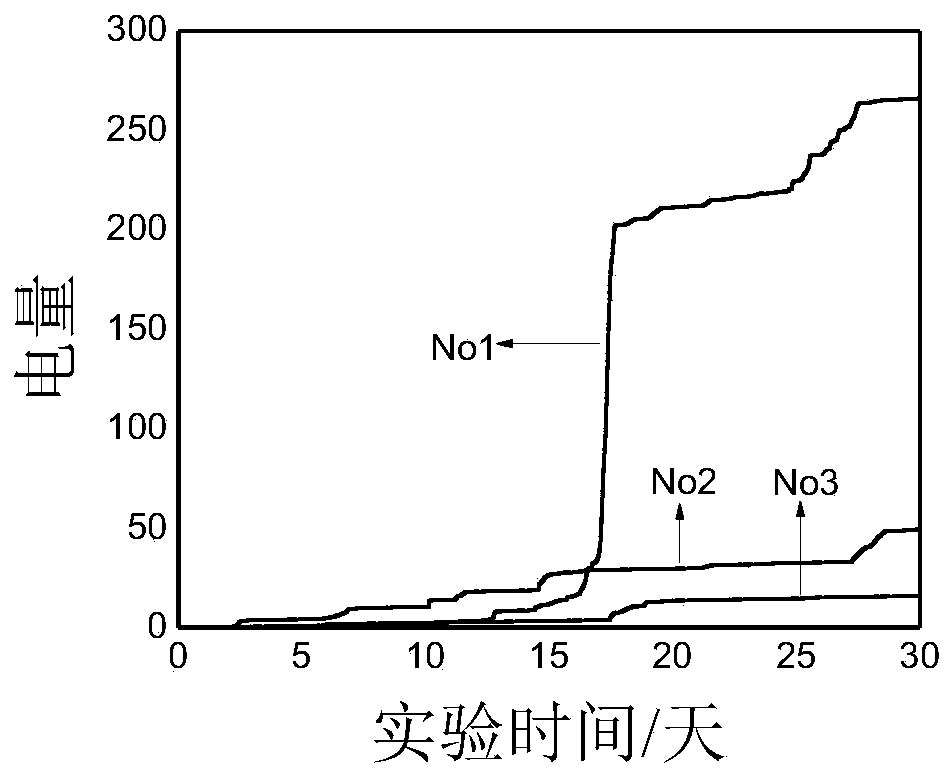

[0034] The electrodes made of three different varieties of weathering steel plates were marked...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com