Dual-cone rotary vacuum dryer

A vacuum dryer, rotary technology, applied in non-progressive dryers, dryers, drying solid materials, etc., can solve the problems of inconsistent pressure in the interlayer, poor temperature uniformity, and slow material acceptance of heat energy, etc., to achieve The maintenance and operation of equipment is simple, the drying time is shortened, and the heat conduction is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

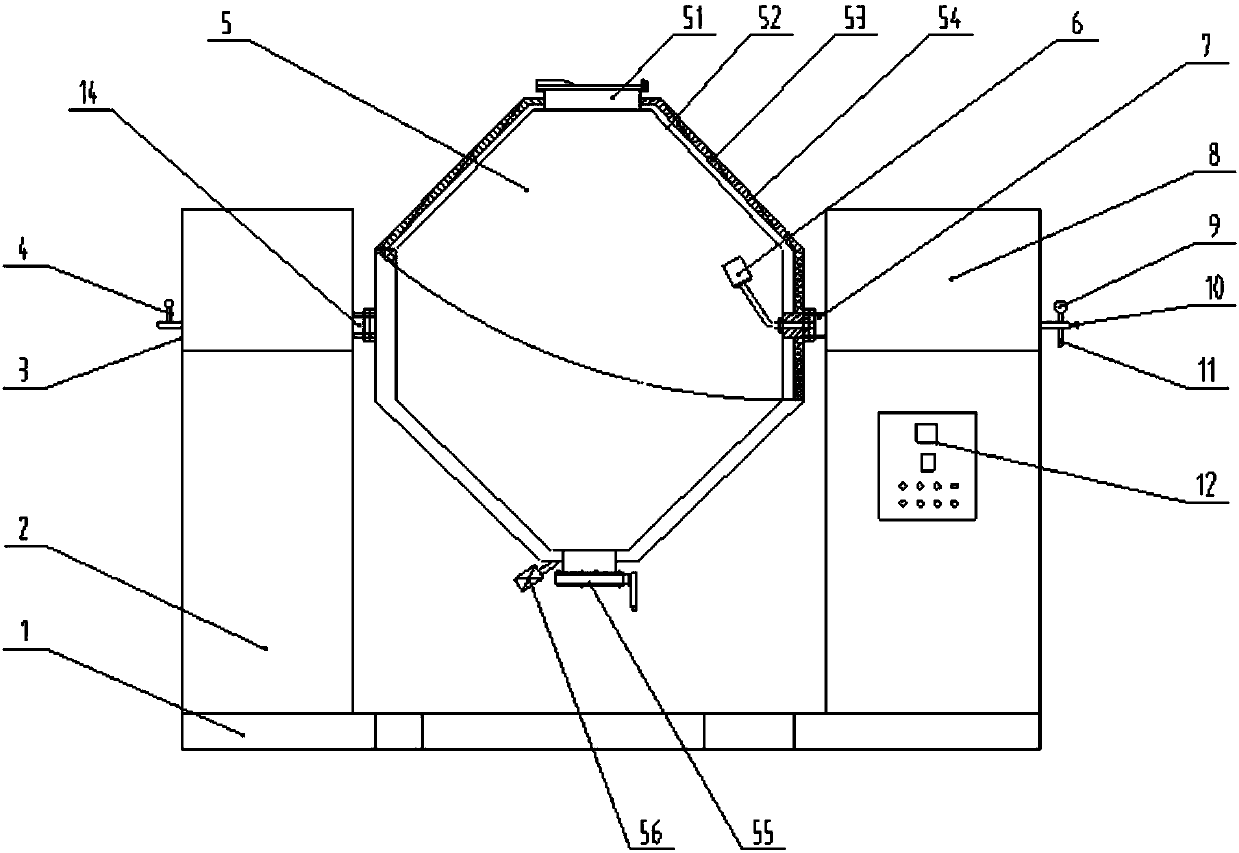

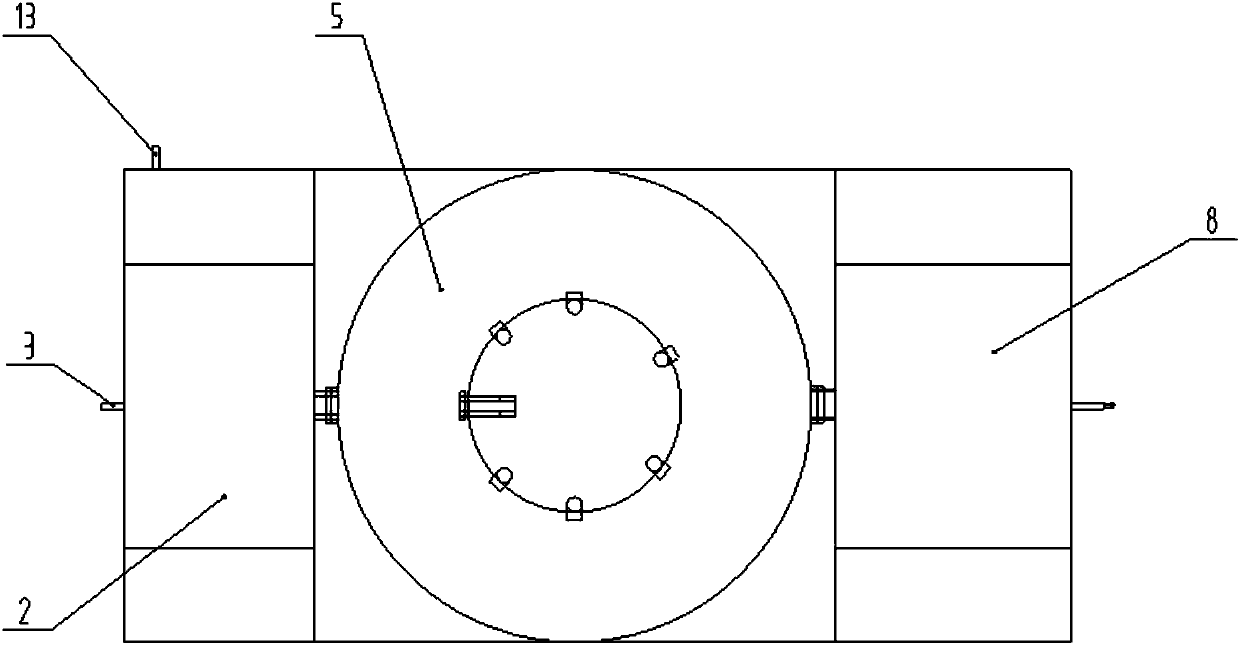

[0017] This embodiment provides a double-cone rotary vacuum dryer with a structure such as figure 1 and figure 2 As shown, it includes: left bracket 2, right bracket 8 and barrel 5, left bracket 2 and right bracket 8 are installed on the two ends of base 1 respectively, first rotating shaft 14 is installed on the top of left bracket 2, first rotating shaft 14 The outer end is provided with a steam inlet 3, a pressure gauge 4 is installed on the outside of the steam inlet 3, a condensed water outlet 13 is arranged on the side below the left bracket 2, a second rotating shaft 7 is installed above the right bracket 8, and the barrel 5 is respectively connected to the first The rotating shaft 14 and the second rotating shaft 7 are connected with bearings. The barrel 5 is a biconical structure with two pointed ends facing away from each other. The barrel 5 includes an outer shell 54 and an inner shell 52, and an interlayer 53 is arranged between the outer shell 54 and the inner sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com