A wear-resistant high-strength corrugated cardboard and its preparation method

A corrugated cardboard, high-strength technology, applied in the field of wear-resistant high-strength corrugated cardboard and its preparation, can solve the problems of damaged corrugated cardboard performance, lack of waterproof and moisture-resistant functions, borax falling off and layering, etc. Scratch and wear, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

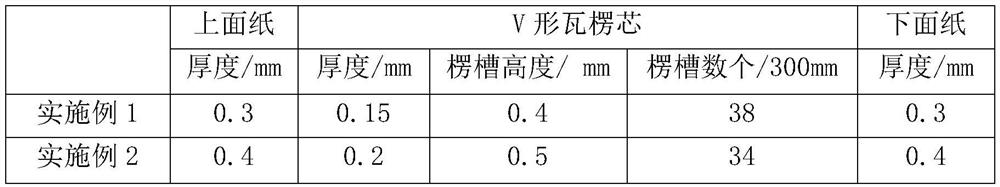

Embodiment 1

[0029] A wear-resistant high-strength corrugated cardboard, the corrugated cardboard is composed of upper paper, V-shaped corrugated core, and lower paper; the V-shaped corrugated core is composed of a base layer of the corrugated core and protective layers applied on both sides of the base layer;

[0030] The corrugated core base layer includes the following raw materials in parts by weight: 100 parts of red pine wood pulp, 30 parts of bamboo wood pulp, 20 parts of fluff pulp, 40 parts of waste paper pulp, 1 part of cyclodextrin, 10 parts of oxidized tapioca starch, and 4 parts of composite reinforcing fiber , 1 part of cationic polyacrylamide, 0.01 part of sodium sorbate, 0.1 part of antimony trioxide, 0.1 part of polyvinyl alcohol with an average molecular weight of 28000, and 5 parts of polydimethylsiloxane; Stone wool, boron carbide fiber, and aluminum borate whiskers are mixed in a weight ratio of 1:0.1:0.1;

[0031] The protective layer is composed of the following comp...

Embodiment 2

[0043] A wear-resistant high-strength corrugated cardboard, the corrugated cardboard is composed of upper paper, V-shaped corrugated core, and lower paper; the V-shaped corrugated core is composed of a base layer of the corrugated core and protective layers applied on both sides of the base layer;

[0044] The corrugated core base layer includes the following raw materials in parts by weight: 100 parts of red pine wood pulp, 50 parts of bamboo wood pulp, 30 parts of fluff pulp, 60 parts of waste paper pulp, 5 parts of cyclodextrin, 15 parts of oxidized tapioca starch, and 8 parts of composite reinforcing fiber , 3 parts of cationic polyacrylamide, 0.1 part of sodium sorbate, 0.3 part of antimony trioxide, 0.5 part of polyvinyl alcohol with an average molecular weight of 35000, and 7 parts of polydimethylsiloxane; Stone wool, boron carbide fiber, and aluminum borate whiskers are mixed in a weight ratio of 1:0.3:0.5;

[0045] The protective layer is composed of the following com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com