Method for preparing surface-hydroxylated iron oxide thin film photoanode material

A technology of iron oxide and photoanode, which is applied in metal material coating process, liquid chemical plating, coating, etc., to achieve the effect of reduced carrier recombination, obvious effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for preparing a surface hydroxylated iron oxide thin film photoanode material, the specific steps are as follows:

[0020] Prepare 20ml of FeCl containing 0.15mol / L 3 and 1mol / L NaNO 3 After fully stirring the solution, take 10ml of the solution and put it into a dyeing vat, then put it into FTO glass, heat it in water at 90°C for 3 hours, and form a uniform yellow β-FeOOH layer, calcinate at 800°C for 20min, and convert it into an iron oxide film; The good iron oxide film is transferred into a low-temperature plasma cleaning machine, and the plasma processing time is set to 60s, the power is 100W, and the air flow rate is 400ml / min. After the treatment, the surface hydroxylated iron oxide film photoanode material is obtained.

[0021] figure 1 is the X-ray diffraction pattern of the prepared iron oxide film, the diffraction peaks at 2θ equal to 35.7 and 54.6 degrees are consistent with the diffraction peaks of ferric oxide, corresponding to the 110 and 116 c...

Embodiment 2

[0023] A method for preparing a surface hydroxylated iron oxide thin film photoanode material, the specific steps are as follows:

[0024] Prepare 20ml of FeCl containing 0.15mol / L 3 and 1mol / L NaNO 3 After fully stirring the solution, take 10ml of the solution and put it into a dyeing vat, then put it into FTO glass, heat it in water at 90°C for 3 hours, and form a uniform yellow β-FeOOH layer, calcinate at 700°C for 30min, and convert it into an iron oxide film; The good iron oxide film is transferred into a low-temperature plasma cleaning machine, and the plasma processing time is set to 150s, the power is 100W, and the nitrogen flow rate is 400ml / min. After the treatment, the surface hydroxylated iron oxide film photoanode material is obtained.

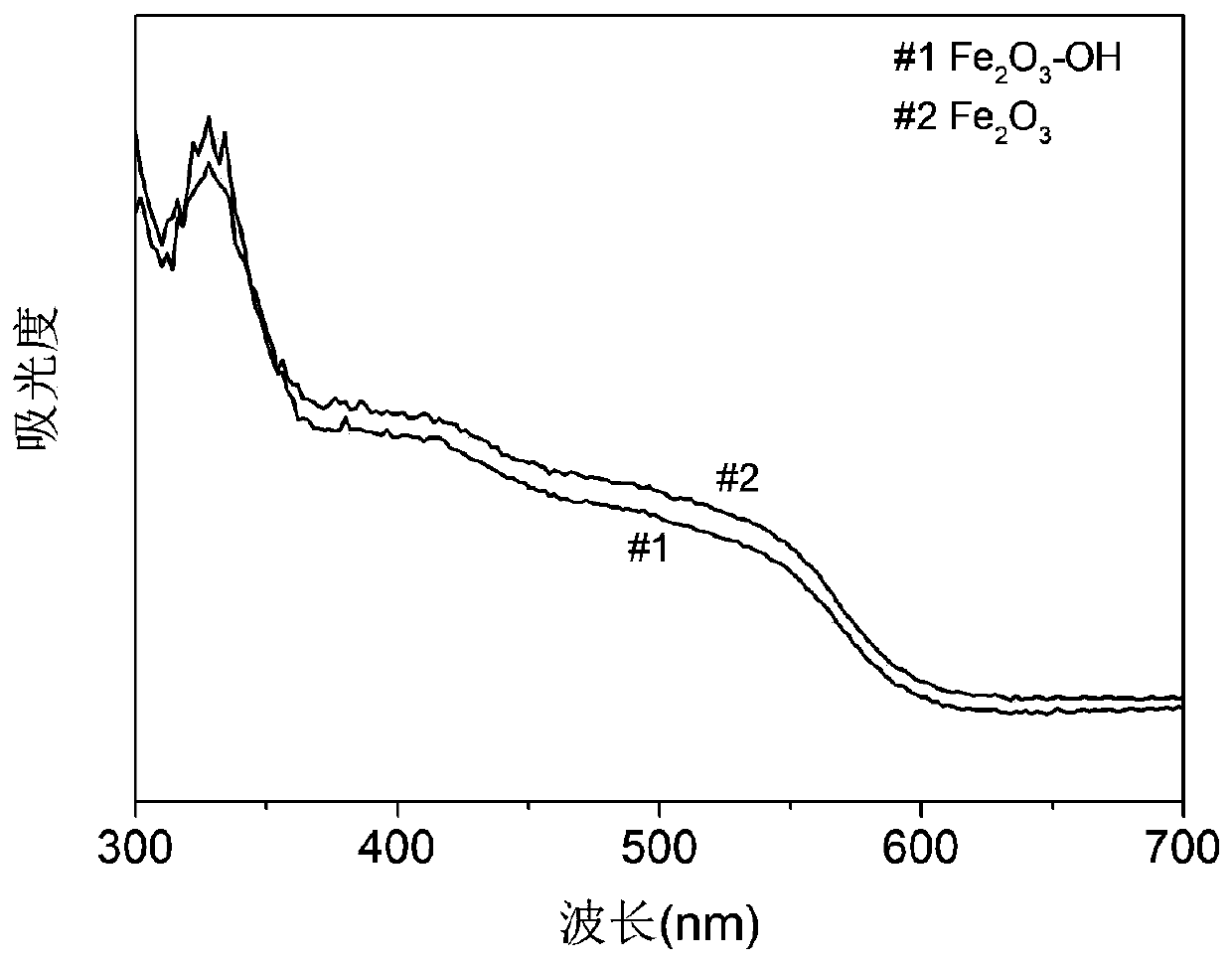

[0025] figure 2 The ultraviolet-visible absorption diffuse reflectance diagram of the prepared iron oxide and the surface hydroxylated iron oxide film shows absorption characteristics in the ultraviolet and visible regions, but...

Embodiment 3

[0027] A preparation method of a surface hydroxylated iron oxide thin film photoanode material, the specific steps are as follows: prepare 20ml of FeCl containing 0.15mol / L 3 and 1mol / L NaNO 3After fully stirring the solution, take 10ml of the solution and put it into a dyeing vat, then put it into FTO glass, heat it in water at 95°C for 2 hours, and form a uniform yellow β-FeOOH layer, first calcinate at 550°C for 20min, then calcinate at 700°C for 30min, and transform It is an iron oxide film; transfer the prepared iron oxide film into a low-temperature plasma cleaning machine, set the plasma processing time to 120s, the power to 150W and the air flow to 400ml / min, and the surface hydroxylated iron oxide is obtained after the treatment is completed Thin film photoanode materials.

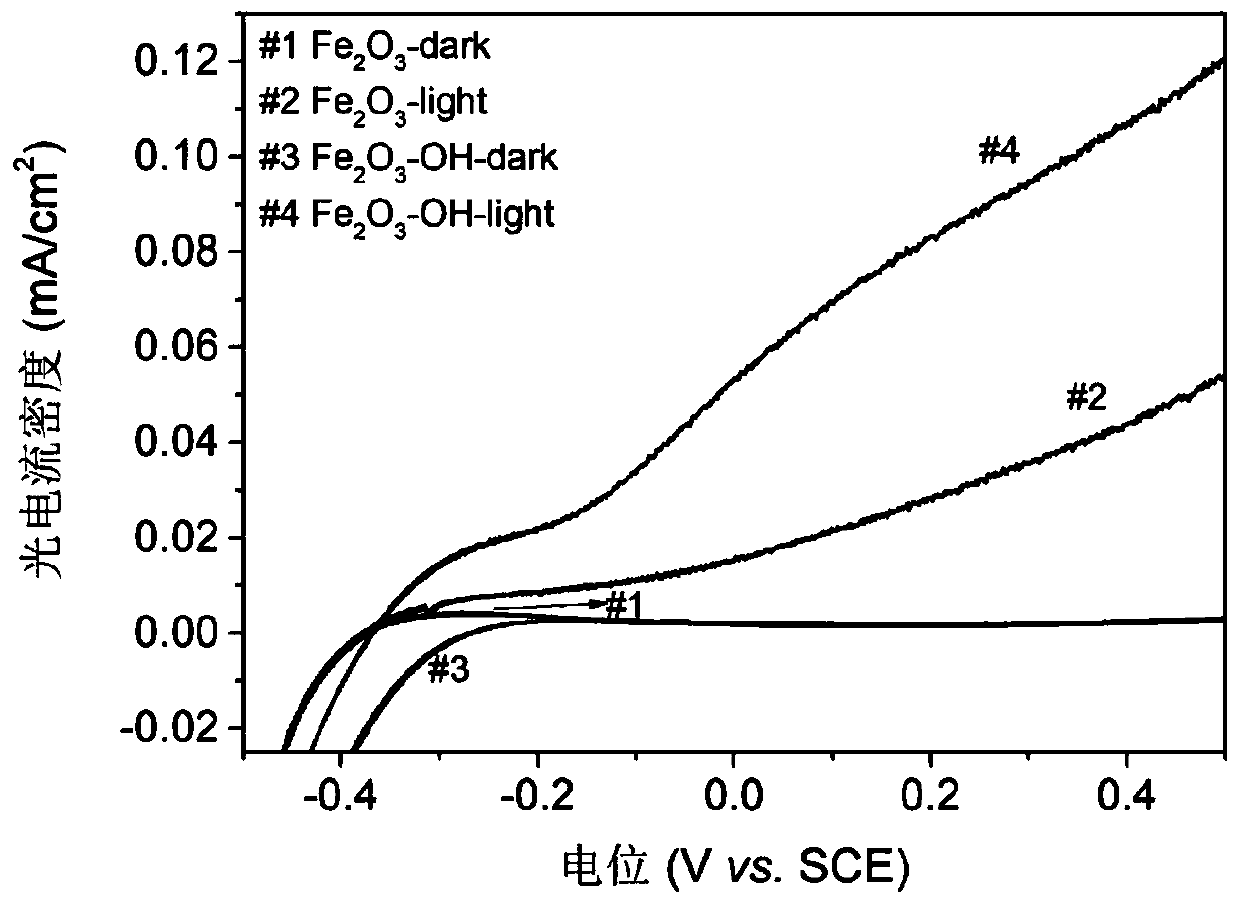

[0028] image 3 It is the linear scan voltammetry curve of iron oxide and surface hydroxylated iron oxide thin film electrode in dark state and light, the scan speed is set to 20mV / s, and the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com