Preparation process of a high thermal conductivity extruded aluminum alloy profile

A technology of aluminum alloy profile and preparation process, which is applied in the field of preparation process of extruded aluminum alloy profile with high thermal conductivity, can solve the problems of high price, low cost performance of products, high cost of engineering cost, etc., achieve high cost performance, safe and reliable electricity consumption, reduce Effect of Line Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

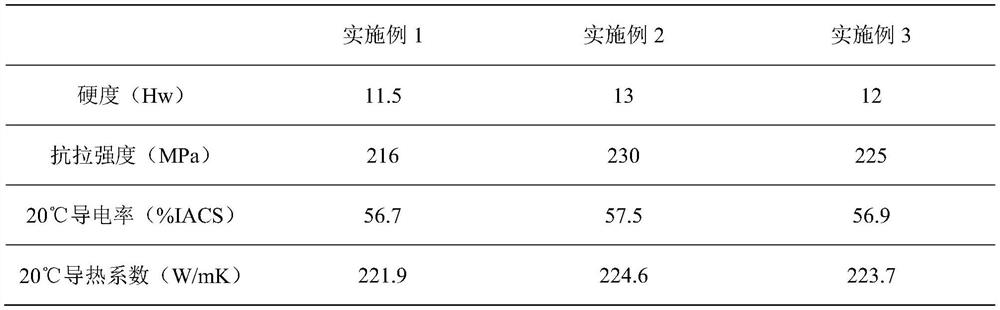

Embodiment 1

[0026] A preparation method of Al-Mg-Si aluminum alloy, by mass percentage: Si 0.33%, Mg 0.52%, Fe 0.12%, Cr and / or Mn 0.005%, V and / or Ti 0.02%, Cu 0.01% , Zn 0.05%, B 0.03%, other unavoidable impurity elements, the mass percentage of the other unavoidable impurity elements is not more than 0.02%, and the balance is Al.

[0027] The preparation steps are as follows:

[0028] 1) Melting and casting: According to the above mass percentage, aluminum is first added to the furnace, heated to 700°C to melt, and then other components except aluminum are added, and the casting rough material is obtained after melting.

[0029] 2) Refining: Control the temperature of the casting rough material described in step 1) at 720°C, add an appropriate amount of refining agent and refining agent, and refine for 15 to 20 minutes. The refining agent is Al-Ti-C or Al- Ti-B, the refining agent is 40% Na 3 AlF 6 +30%NaCl+30%KCl composition; then control the temperature at 680°C and let it stand f...

Embodiment 2

[0033] A method for preparing Al-Mg-Si aluminum alloy, by mass percentage: Si 0.35%, Mg 0.55%, Fe 0.12%, Cr and / or Mn 0.005%, V and / or Ti 0.02%, Cu 0.01% , Zn 0.05%, B 0.03%, other unavoidable impurity elements, the mass percentage of the other unavoidable impurity elements is not more than 0.02%, and the balance is Al.

[0034] The preparation steps are as follows:

[0035] 1) Melting and casting: According to the above mass percentage, aluminum is first added to the furnace, heated to 750°C to melt, and then other components except aluminum are added, and the casting rough material is obtained after melting.

[0036] 2) Refining: Control the temperature of the casting rough material described in step 1) at 730°C, add an appropriate amount of refining agent and refining agent, and refine for 18 minutes. The refining agent is Al-Ti-C or Al-Ti- B, the refining agent is 40% Na 3 AlF 6 +30%NaCl+30%KCl composition; then control the temperature at 700°C and let it stand for 15 to ...

Embodiment 3

[0040] A preparation method of Al-Mg-Si aluminum alloy, by mass percentage: Si 0.35%, Mg 0.56%, Fe0.08%, Cr and / or Mn≤0.004%, Ti 0.01%, Cu≤0.001%, Zn 0.04%, B 0.011%, other unavoidable impurity elements, the mass percentage of the other unavoidable impurity elements is not more than 0.02%, and the balance is Al.

[0041] The preparation steps are as follows:

[0042] 1) Melting and casting: According to the above mass percentage, aluminum is first added to the furnace, heated to 800°C to melt, and then other components except aluminum are added, and the casting rough material is obtained after melting.

[0043] 2) Refining: Control the temperature of the casting rough material described in step 1) at 740°C, add an appropriate amount of refining agent and refining agent, and refine for 20 minutes. The refining agent is Al-Ti-C or Al-Ti- B, the refining agent is 40% Na 3 AlF 6 +30%NaCl+30%KCl composition; then control the temperature at 710°C and let it stand for 20min to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com