A kind of air preheater chemical cleaning agent

A technology of air preheater and cleaning agent, which is applied in the direction of detergent compounding agent, detergent composition, chemical equipment and methods, etc., and can solve the problem of ash plugging, affecting the normal operation of the heat exchange boiler of the preheater, corrosion of the preheater, etc. problems, achieve the effect of reducing adhesion, reducing the clogging rate of air preheater, and prolonging the running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A chemical cleaning agent for an air preheater, comprising an alkali agent, an emulsifier and an additive, the emulsifier being sodium dodecylbenzene sulfonate, sodium alkyl succinate sulfonate, polyoxyethylene alkyl ether, and the additive being alkane Base benzene sulfonate, polyamide, organosilicon, trisodium phosphate, alkali agent is sodium hydroxide, the content of each component is: sodium dodecylbenzene sulfonate content of 20% by mass, alkyl sulfosuccinate The mass percentage content of sodium bicarbonate is 25%, the mass percentage content of polyoxyethylene alkyl ether is 15%, the mass percentage content of alkylbenzene sulfonate is 15%, the polyamide mass percentage content is 6%, and the organic silicon mass percentage content is 5%, the mass percentage content of trisodium phosphate is 10%, and the mass percentage content of sodium hydroxide is 4%. Stir and mix the components evenly to prepare the air preheater chemical cleaning agent.

[0025] A newly in...

Embodiment 2

[0031] In this embodiment, the cleaned 700MW coal-fired unit #1 boiler A and B side air preheaters in the embodiment 1 are cleaned again after running under the same conditions for the same time. The proportioning and consumption of the air preheater chemical cleaning agent used are exactly the same as in Example 1. The cleaning method is also completely consistent with the cleaning process.

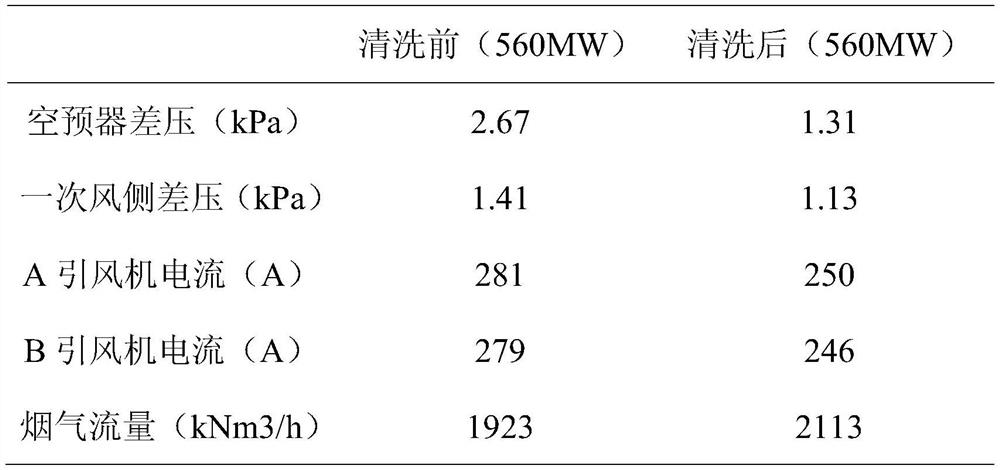

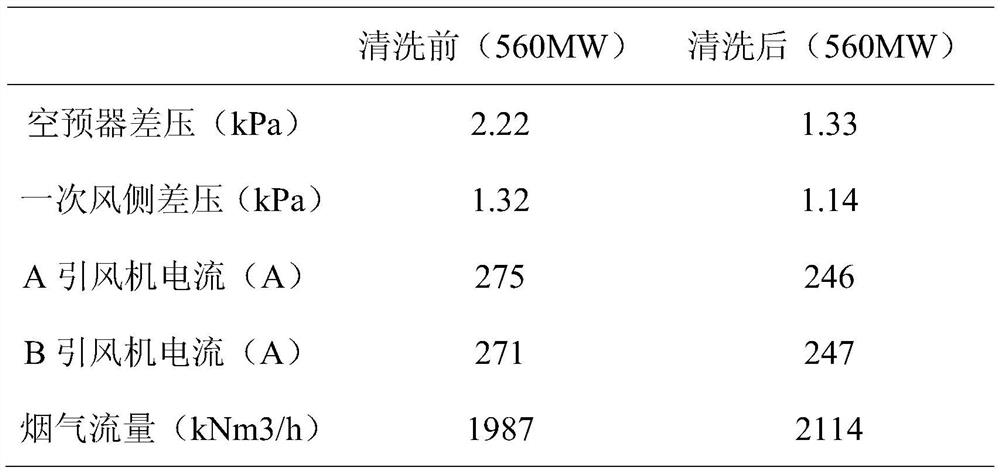

[0032] After the air preheater is cleaned, the differential pressure is significantly reduced, and the current of the induced draft fan is significantly reduced, achieving the expected effect. The operating parameters before and after cleaning under the same load are compared in the table below.

[0033]

[0034] Compared with Example 1, after running for a week under the same conditions, the adhesion of dirt has decreased, indicating that the passivation film formed by the cleaning agent on the metal surface of the air preheater can effectively reduce the adhesion rate of dirt and p...

Embodiment 3

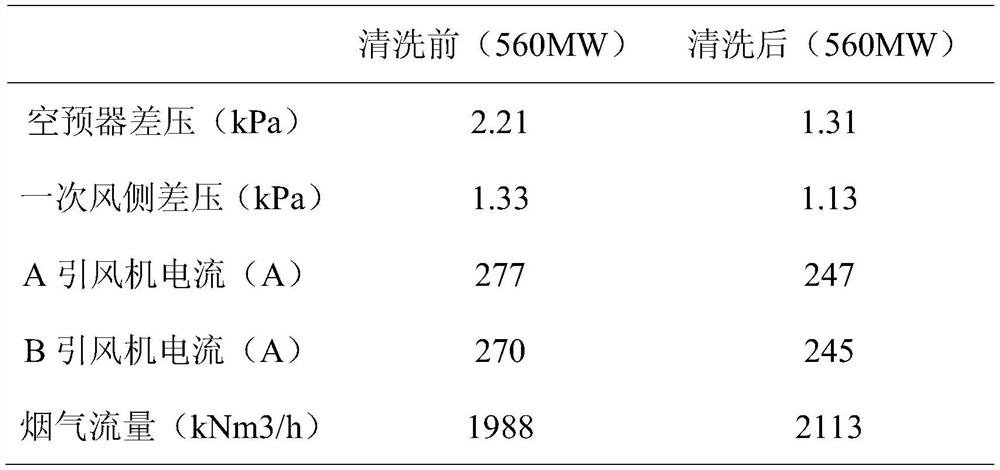

[0036] In this embodiment, the cleaned 700MW coal-fired unit #1 boiler A, B side air preheater in embodiment 2 is cleaned again after running under the same conditions for the same time. The proportion of the cleaning agent has been slightly adjusted. The chemical cleaning agent used for the air preheater contains alkali agent, emulsifier and additives. The emulsifier is sodium dodecylbenzene sulfonate, sodium alkyl succinate sulfonate, polyoxyethylene Alkyl ether, additives are alkylbenzene sulfonate, polyamide, organosilicon, trisodium phosphate, alkali agent is sodium hydroxide, the content of each component is: sodium dodecylbenzene sulfonate, the mass percentage content is 19% , the mass percentage content of sodium alkyl ester sulfosuccinate is 24%, the mass percentage content of polyoxyethylene alkyl ether is 14%, the mass percentage content of alkylbenzene sulfonate is 15.5%, and the mass percentage content of polyamide is 6.5% %, the mass percentage content of organic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com