Three-dimensional cross-linked structure MXene material and preparation method thereof

A technology of three-dimensional cross-linking and three-dimensional structure, which is applied in the field of electrochemical energy storage, can solve the problems of long ion transmission path and achieve the effects of shortening the transmission distance, benefiting long-term storage and good electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Step 1: Make 2D-MXene nanosheets ultrasonically into a dispersion with 1-20 layers, with a concentration of 0.5-5 mg / mL;

[0042] Step 2: Spray the solution obtained in Step 1 into the boiling liquid nitrogen with droplets with a diameter of 100 μm to 5000 μm through a high-pressure gun;

[0043] Step 3: After the liquid nitrogen in step 2 is volatilized and dried, the obtained product is subjected to freeze-drying treatment to obtain 3D-MXene with a non-stack structure.

Embodiment 2

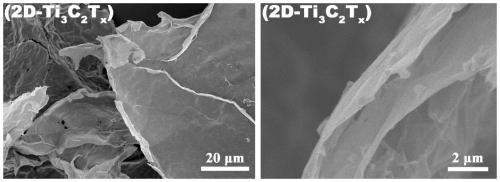

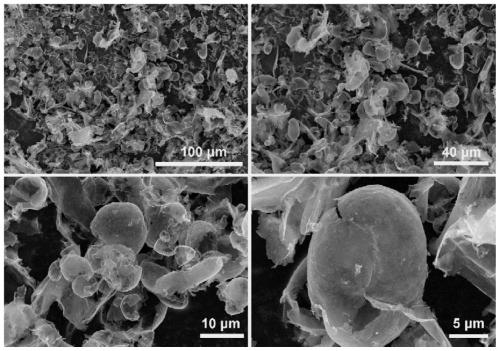

[0045] This embodiment is basically the same as step 1 of embodiment, the difference is that in step 1, MXene is selected as 2D-Ti 3 C 2 T x And be made into the solution of 2mg / ml; In step 2, spray the droplet that is 100 μ m in diameter into liquid nitrogen; And the obtained 3D-Ti 3 C 2 T x The material uses NMP as a solvent to obtain a porous electrode by means of stirring and coating.

[0046] figure 2 3D-Ti with crosslinked spherical and tubular structures prepared for this example 3 C 2 T x ,and figure 1 In stark contrast to the original morphology in

[0047] Figure 5 Porous 3D-Ti prepared for this example 3 C 2 T x Electrodes and pristine 2D-Ti 3 C 2 T x Stacked electrodes made of materials; where (a) (b) is porous 3D-Ti 3 C 2 T x , (c)(d) is the stacked 2D-Ti 3 C 2 T x .

[0048] Figure 6 Porous 3D-Ti prepared for this example 3 C 2 T x Electrode with pristine 2D-Ti 3 C 2 T x Comparison of the rate performance of electrodes prepared f...

Embodiment 3

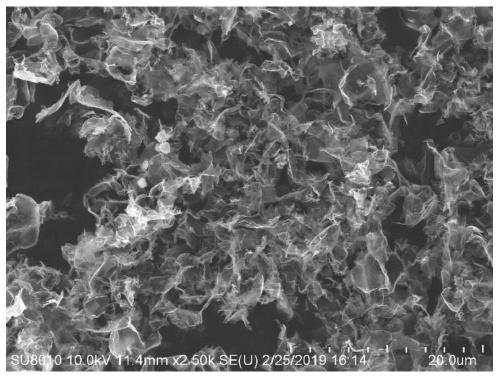

[0050] The steps of this embodiment are basically the same as those of Embodiment 2, except that the concentration in step 1 is changed to 4 mg / ml. The 3D-Ti prepared in this example 3 C 2 T x Three-dimensional wrinkled shape. The wrinkled 3D-Ti prepared in this example 3 C 2 T x Such as image 3 As shown, the curling of the nanosheets was not complete due to the high concentration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com