Gear grinding machine

A gear grinding machine and machine body technology, which is applied in the field of gear grinding machines, can solve problems such as difficult maintenance, difficult disassembly and assembly, and unreasonable structural design and layout, and achieve the effects of reducing production costs, reasonable weight distribution, and reducing equipment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

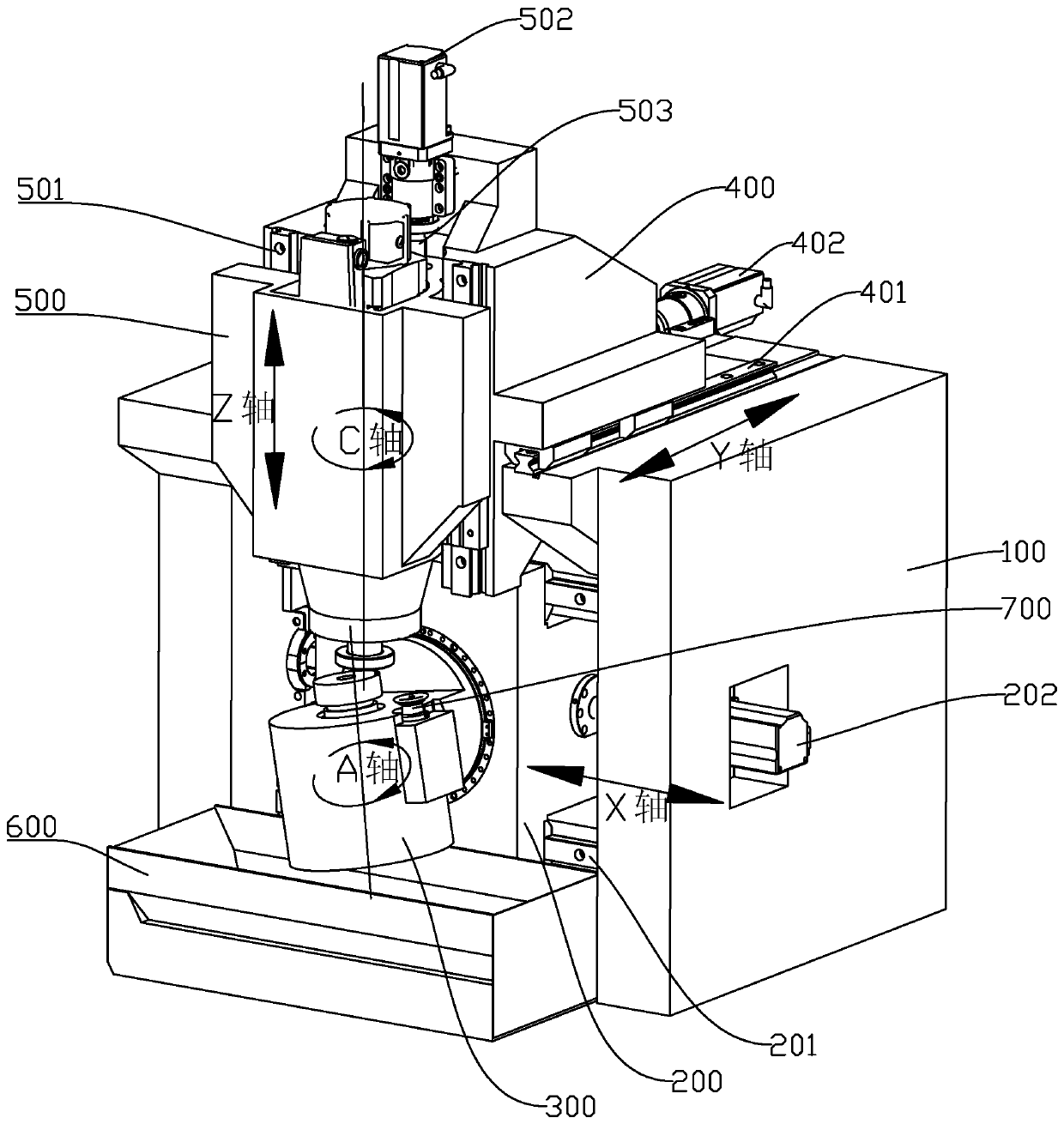

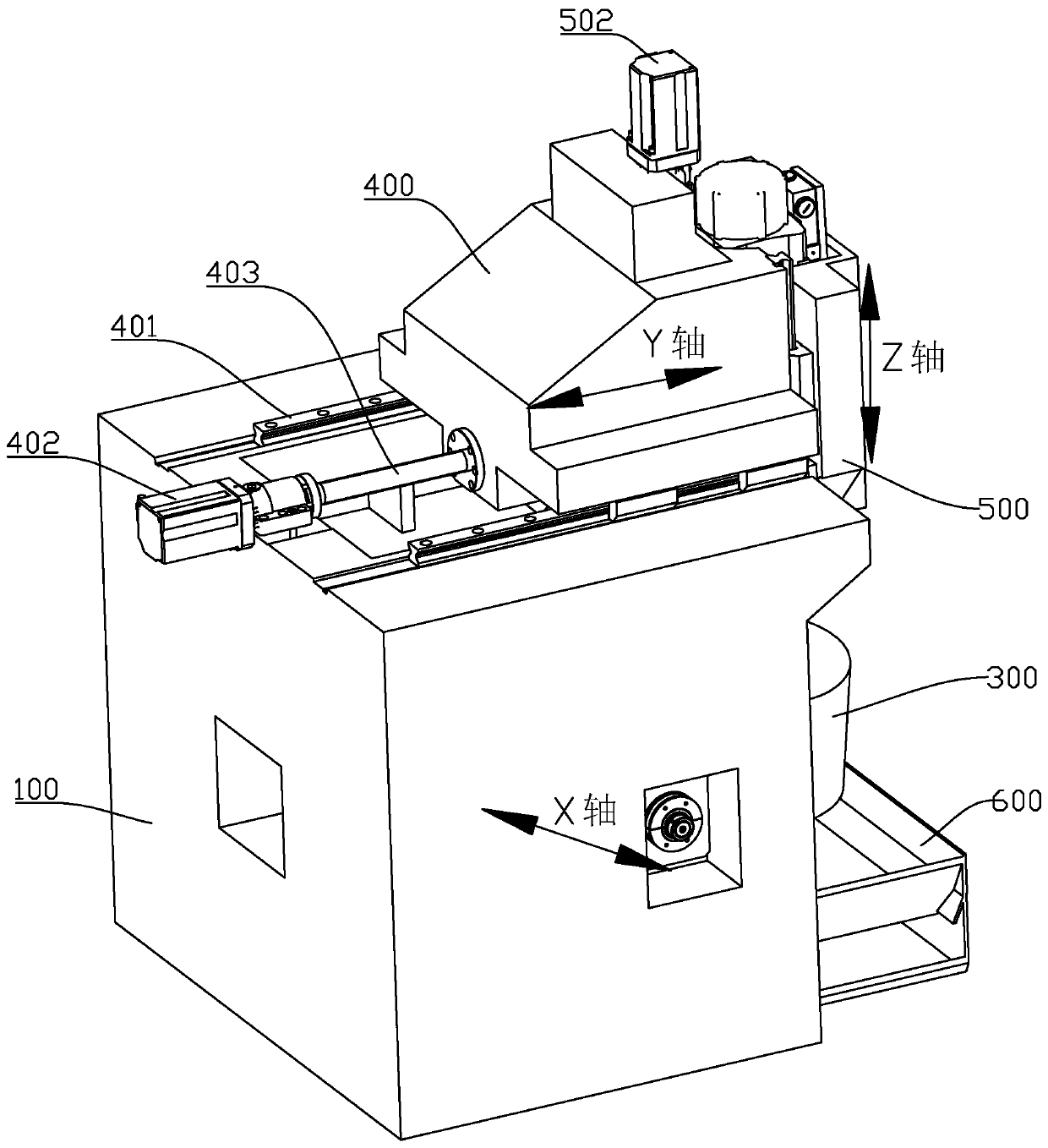

[0030] refer to Figure 1 ~ Figure 3 , the present invention provides a gear grinding machine, comprising:

[0031] A fuselage 100, the side wall of the fuselage 100 is provided with an X-axis guide rail 201 extending along the horizontal axis in the direction of the X-axis;

[0032] The second rotary axis box 200, the second rotary axis box 200 is slidably installed on the X-axis guide rail 201, and the second rotary axis box 200 is provided with a rotary axis B that is horizontal and perpendicular to the X-axis guide rail 201 shaft, the end of the shaft of the rotary shaft B extends outside the second rotary shaft box 200 and is fixedly installed with the first rotary shaft box 300, the first rotary shaft box 300 is provided with a shaft perpendicular to the rotary shaft B the workpiece spindle A axis of the axis, the end of the workpiece spindle A axis is mounted with the workpiece;

[0033] The slide table 400, the slide table 400 is installed on the fuselage 100 so as t...

Embodiment 2

[0050] This embodiment takes Embodiment 1 as the main body, and the difference is that the first drive mechanism, the second drive mechanism and the third drive mechanism in this embodiment are set as linear motors, cylinders or oil cylinders, which directly control the movement of corresponding components, Reduce the setting of the screw rod to achieve the purpose of structural optimization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com