A kind of leakage plate bottom leakage nozzle forming mold and using method thereof

A technology for forming molds and bushings, used in manufacturing tools, perforating tools, glass manufacturing equipment, etc., can solve the problems of bushing bottom plate deformation, bottom plate deformation, uneven length, etc., to ensure molding quality, processing accuracy, guarantee The effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

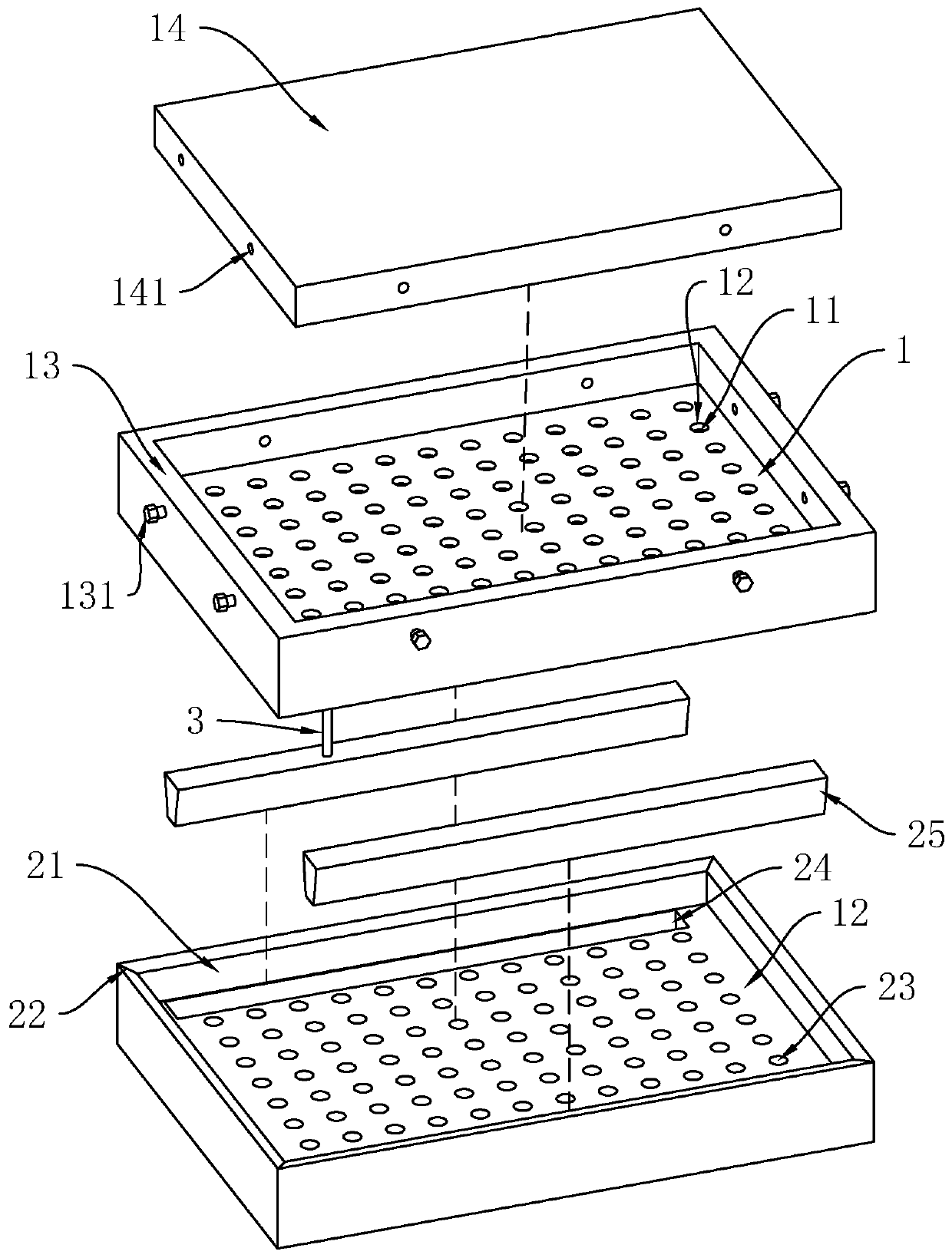

[0040] Embodiment one: refer to figure 1 , is a mold for forming a plug plate bottom plate leak nozzle disclosed by the present invention, including an upper template 1 and a lower template 2 .

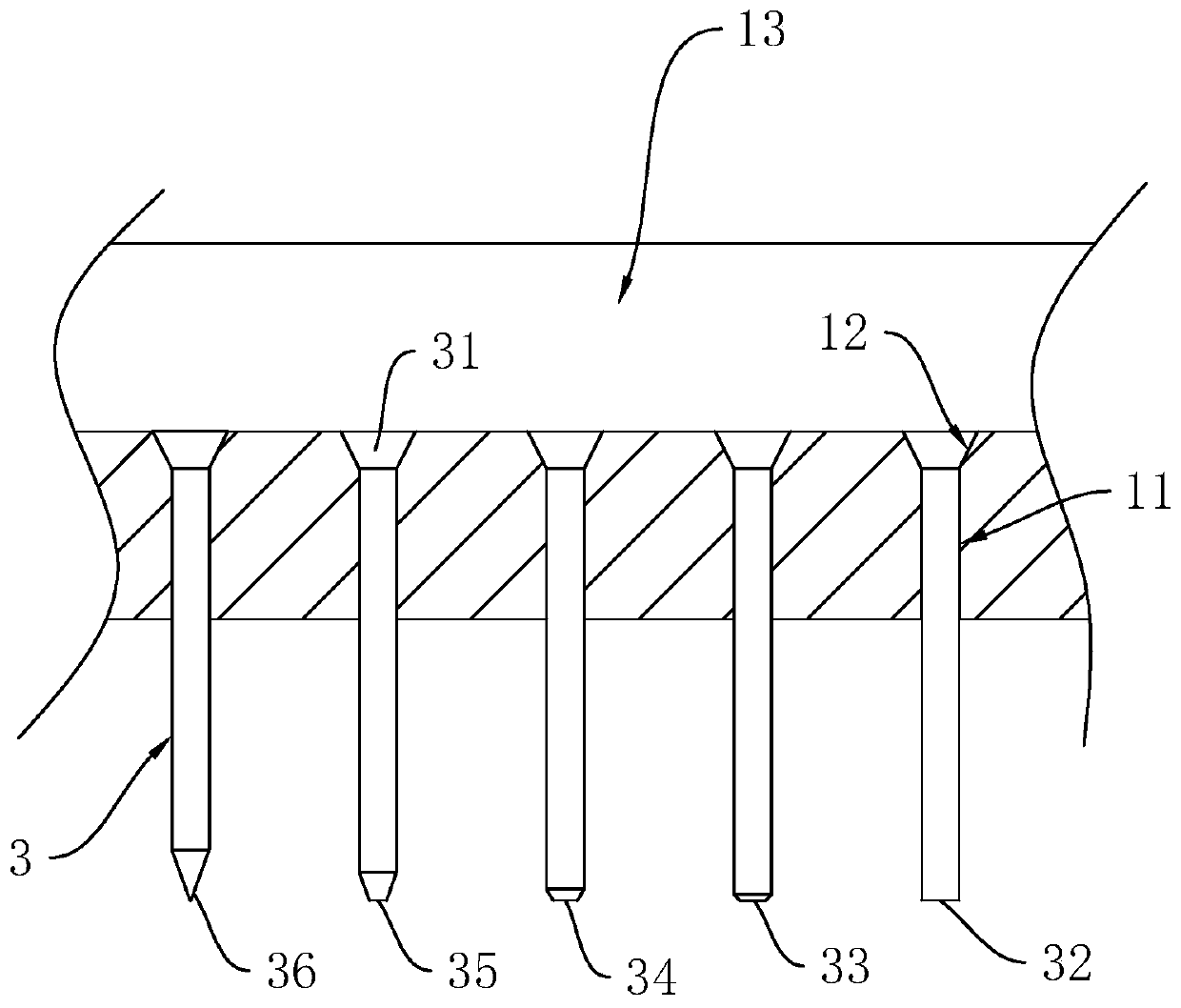

[0041] A number of installation through holes 11 are evenly opened on the upper template 1, and punching needles 3 whose lower ends extend out of the lower side of the installation through holes 11 are inserted in the installation through holes 11, and a tapered positioning hole is opened at the upper end of the installation through holes 11 12. The upper ends of the punching pins 3 are fixedly connected with a tapered tailstock 31, and after the punching pins 3 are inserted in the installation through hole 11, the tapered tailstock 31 can abut against the tapered positioning hole 12, Thereby, the punching needle 3 is prevented from detaching from the underside of the installation through hole 11 . A connecting frame 13 is affixed to the upper side of the upper template 1, and a pres...

Embodiment 2

[0045] Embodiment 2 is a method for using a mold for forming a leaky nozzle of a leaky plate bottom plate disclosed by the present invention, which includes the following steps:

[0046] Step 1, installation of the bushing bottom plate: place the bushing bottom plate in the accommodation groove 21 of the lower formwork 2, so that the bottom plate of the bushing bottom plate abuts against the bottom surface of the accommodation groove 21;

[0047] Step 2, positioning stamping of the bushing bottom plate: install the first punching needles 32 in two rows on the upper template 1, and drive the first punching needles 32 on the upper surface of the bushing bottom plate on the lower template 2 through the upper template 1 Stamping is carried out so that several cylindrical depressions with the same spacing are formed on the upper surface of the bottom plate of the leakage plate, which is the upper end position of the leakage nozzle. The stamping pressure of the upper template 1 is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com