A vehicle winding coil wire head stranding machine

A technology of winding coils and stranding machines, applied in the direction of electromechanical devices, electric components, manufacturing motor generators, etc., can solve the problems of poor quality, slow twisting speed, etc., and achieve good quality, stable twisting force, and consistent pitch Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

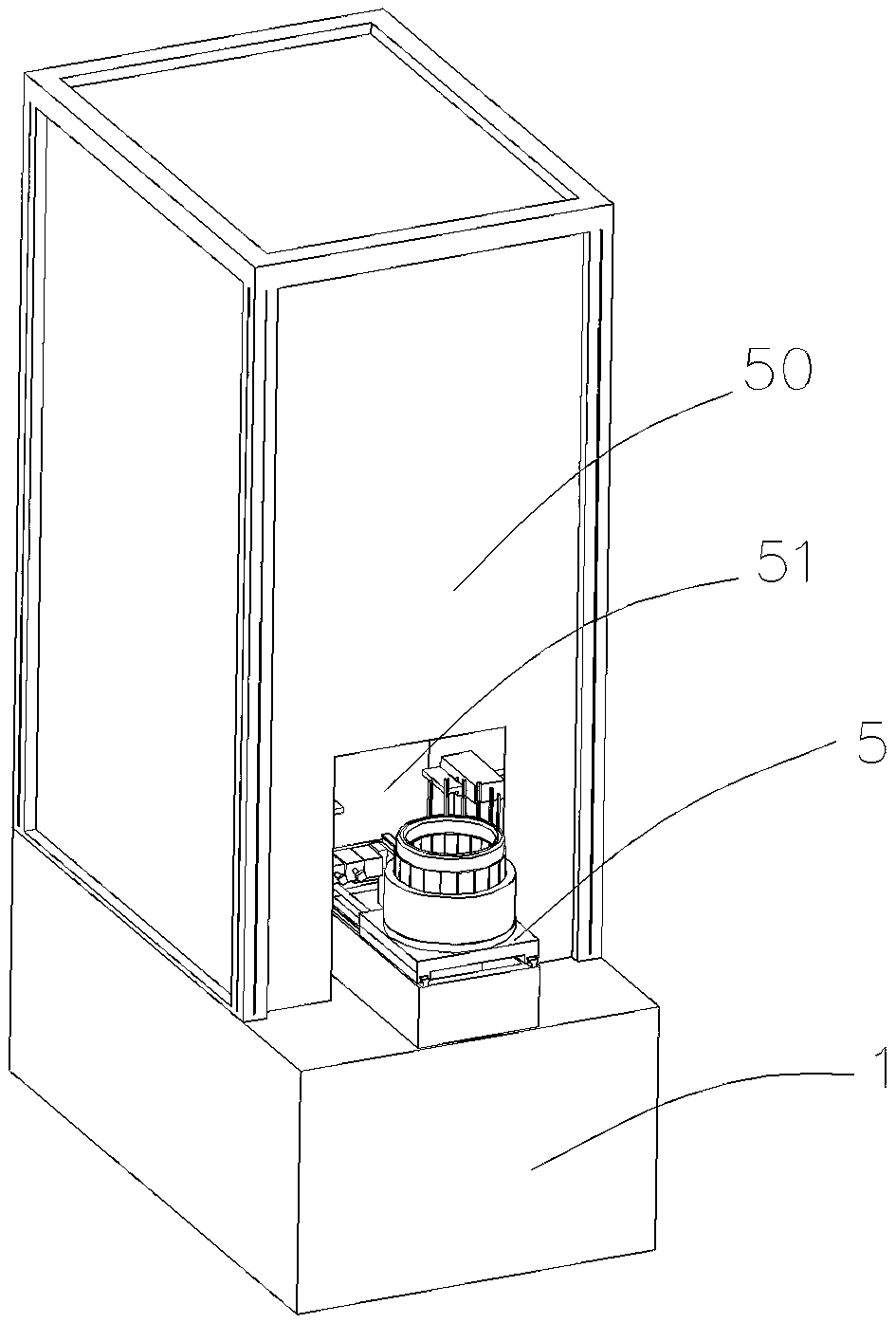

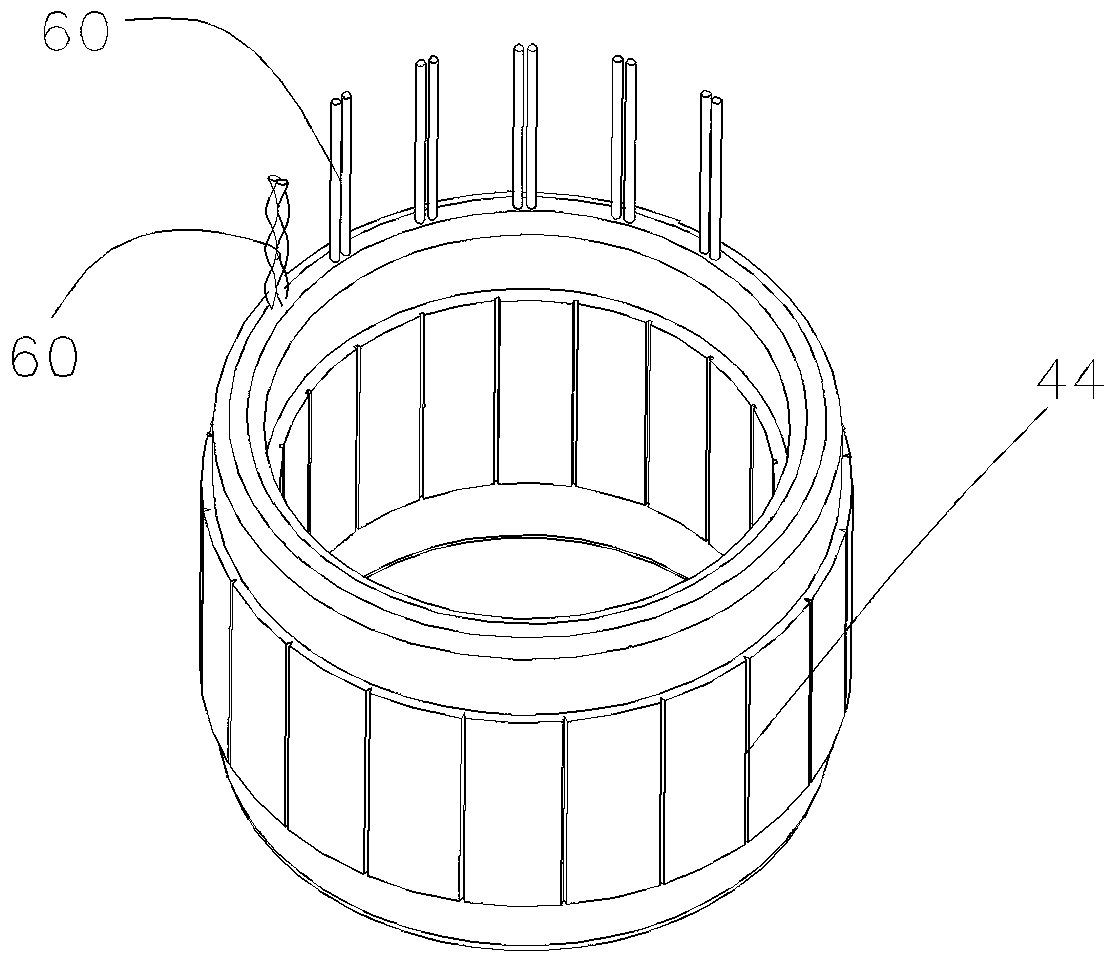

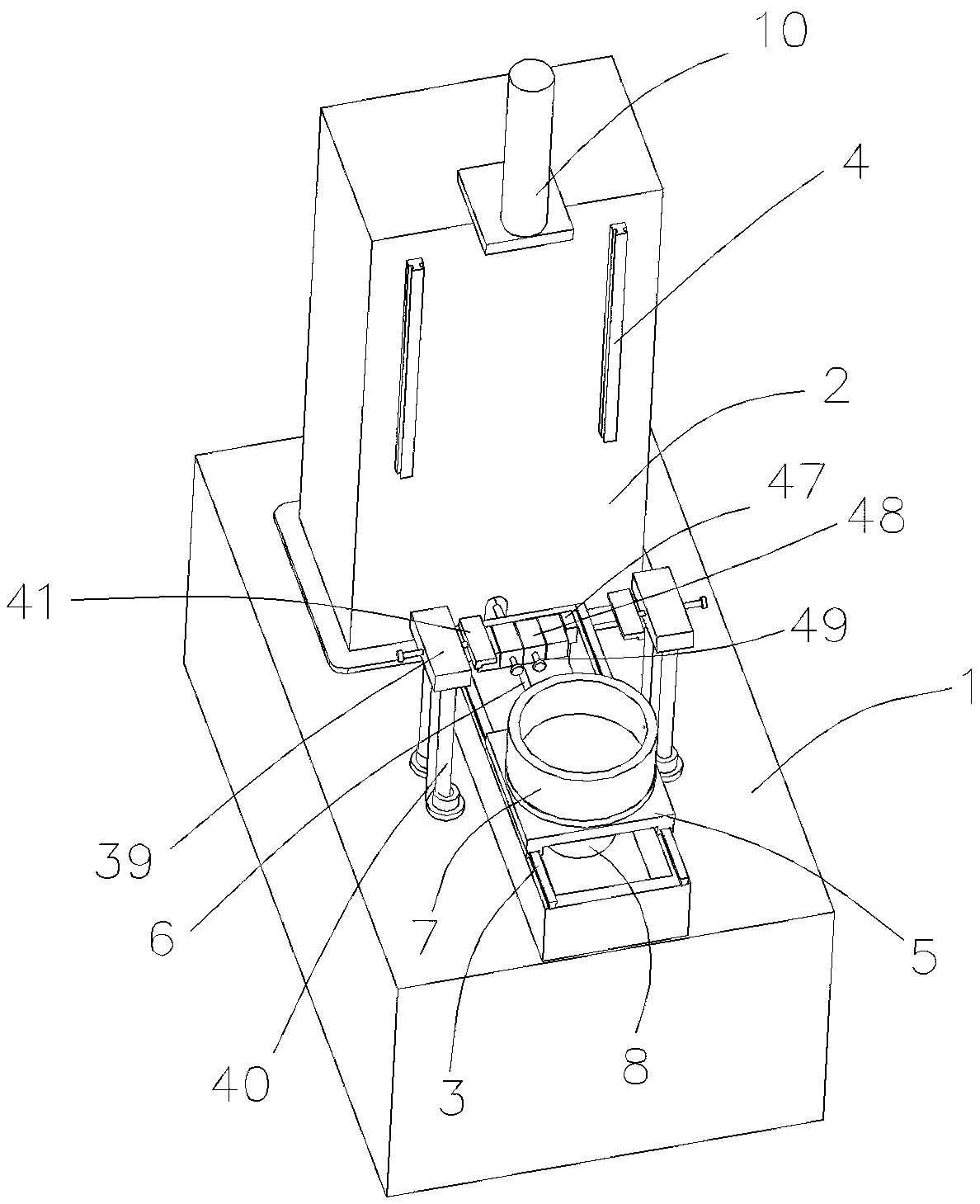

[0027] combined with Figures 1 to 11 , a kind of winding coil end stranding machine for vehicle, comprising a fuselage 1, a stand 2 is arranged on the fuselage 1, a horizontal guide rail 3 is arranged on the fuselage 1, and a vertical guide rail 3 is arranged on the stand 2 There is a vertical guide rail 4, and a clamp table 5 is slidably arranged on the horizontal guide rail 3, and the clamp table 5 is connected to a clamp table cylinder assembly 6 that drives the clamp table 5 to move back and forth on the horizontal guide rail 3, and the described clamp table 5 is provided with a fixture turntable 7, and a turntable motor 8 that drives the fixture turntable 7 to rotate is provided below the fixture table 5;

[0028] A workbench 9 capable of moving up and down is provided on the vertical guide rail 4, and a workbench cylinder asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com