Processing and installation method of anode horizontal bus bar of large electrolytic cell

A horizontal busbar and installation method technology, which is applied in the field of processing and installation of anode horizontal busbars in large-scale electrolytic cells, can solve the problems that the equipment cannot meet the requirements of processing and installation, and affect the energy consumption and efficiency of electrolytic cells, so as to improve the qualified rate of drilling and improve the quality of installation , Guarantee the effect of drilling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

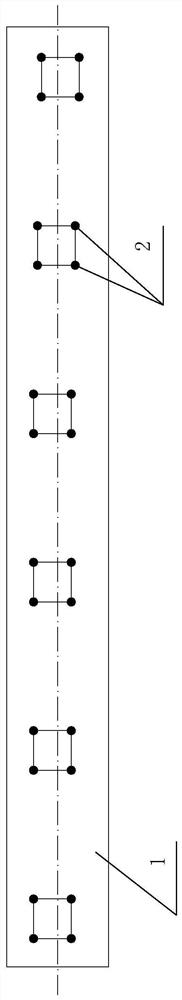

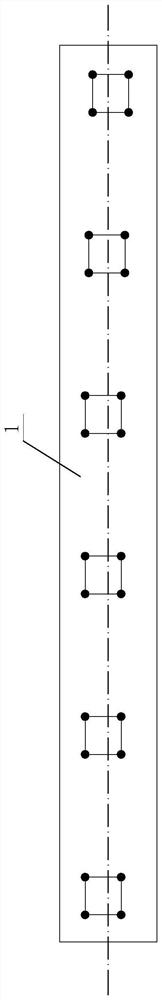

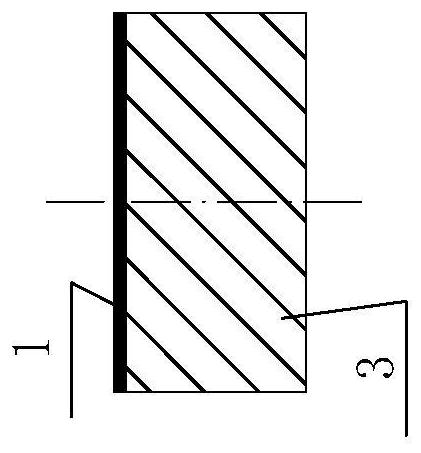

[0028] The method for processing and installing the anode horizontal busbar of a large-scale electrolytic cell of the present invention includes a machining method for the anode horizontal busbar and an installation method for the anode horizontal busbar.

[0029] Among them, the machining method of the anode horizontal bus includes straightening the anode horizontal bus, milling the end face of the anode horizontal bus, laying out the wire on the anode horizontal bus and using a template to locate the position to be drilled, fixing the positioning plate on the anode horizontal bus and drilling Holes, milling the contact plane of the anode horizontal busbar, and the steps of intermediate inspection and acceptance of the anode horizontal busbar.

[0030] Straightening the anode horizontal busbar in the machining method of the anode horizontal busbar refers to placing the anode horizontal busbar on the straightening mold platform, and using a hydraulic jack to straighten the anod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com