Multilayer circuit board with high mechanical drilling yield and manufacturing method thereof

A multi-layer circuit and mechanical drilling technology, applied in the direction of multi-layer circuit manufacturing, printed circuit manufacturing, printed circuit, etc., can solve the problems of increasing production cost, increasing false positive rate, time-consuming and laborious, etc., and improving drilling qualification efficiency, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

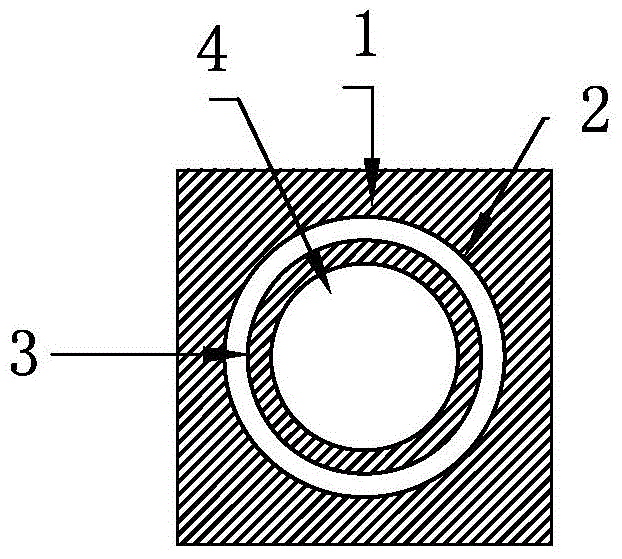

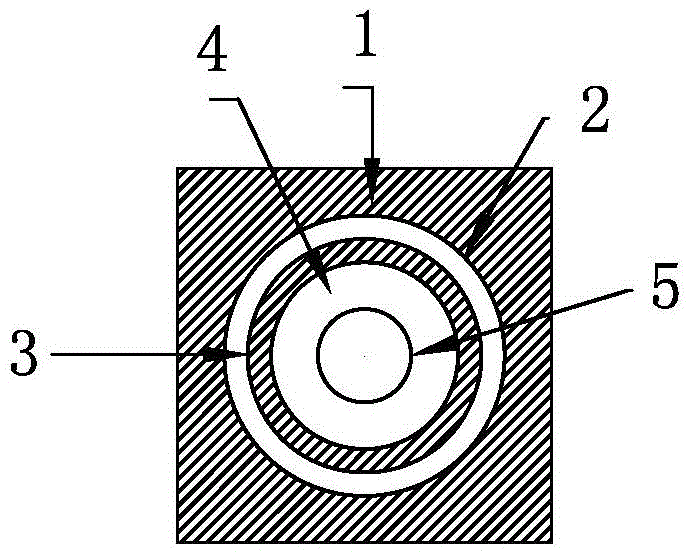

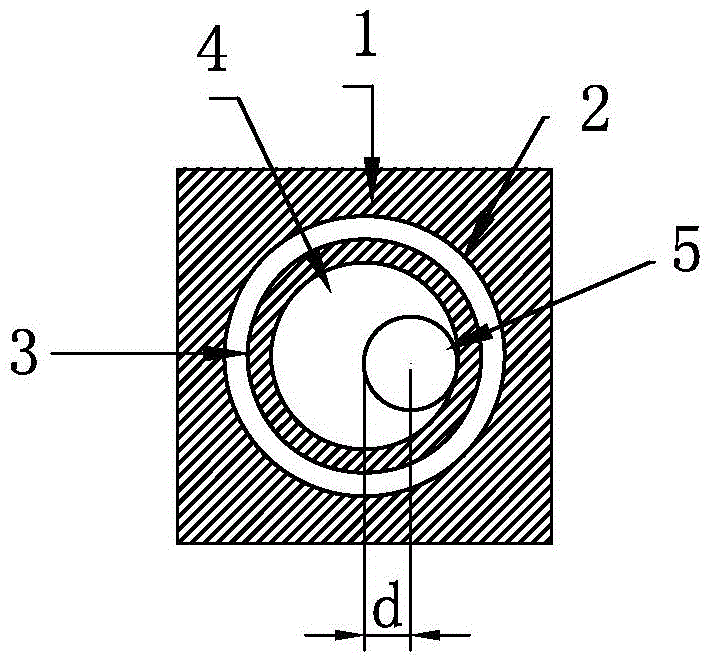

[0042] The multilayer circuit board with high mechanical drilling yield of the present invention can be a multilayer rigid-flex board or a multilayer flexible circuit board.

[0043] Multilayer circuit board of the present invention is made according to the following steps:

[0044] 1) Before laminating at least one layer of hard board made of FR-4 epoxy glass fiber board or No-Flow PP board and at least one layer of soft board made of PI material according to the method of the prior art, the multiple Select a layer of preset soft boards that have been routed in the first layer of circuit boards.

[0045] 2) Making the same original drill tape as the circuit on the preset flexible board, provided with via holes for the circuit to be drilled.

[0046] 3) On the original drill tape, 3-5 identification holes (not identified in the figure) with the same diameter as the circuit conduction hole are arranged staggeredly, and the position of the identification hole corresponds to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com